Information injection-pump assembly

ZEXEL

101608-9230

1016089230

NISSAN-DIESEL

16713Z6665

16713z6665

Rating:

Cross reference number

ZEXEL

101608-9230

1016089230

NISSAN-DIESEL

16713Z6665

16713z6665

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8260

Bosch type code

9 430 610 133

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8921

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.8

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

95

93.4

96.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

280

280

280

Average injection quantity

mm3/st.

12

11

13

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.8)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

95

94

96

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.9

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

100.5

96.5

104.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

125

135

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

970--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

920

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

(1000)

Advance angle

deg.

1.5

1

2

Timer adjustment_04

Pump speed

r/min

1160

Advance angle

deg.

1.5

1

2

Timer adjustment_05

Pump speed

r/min

1450

Advance angle

deg.

7

6.5

7.5

Remarks

Finish

Finish

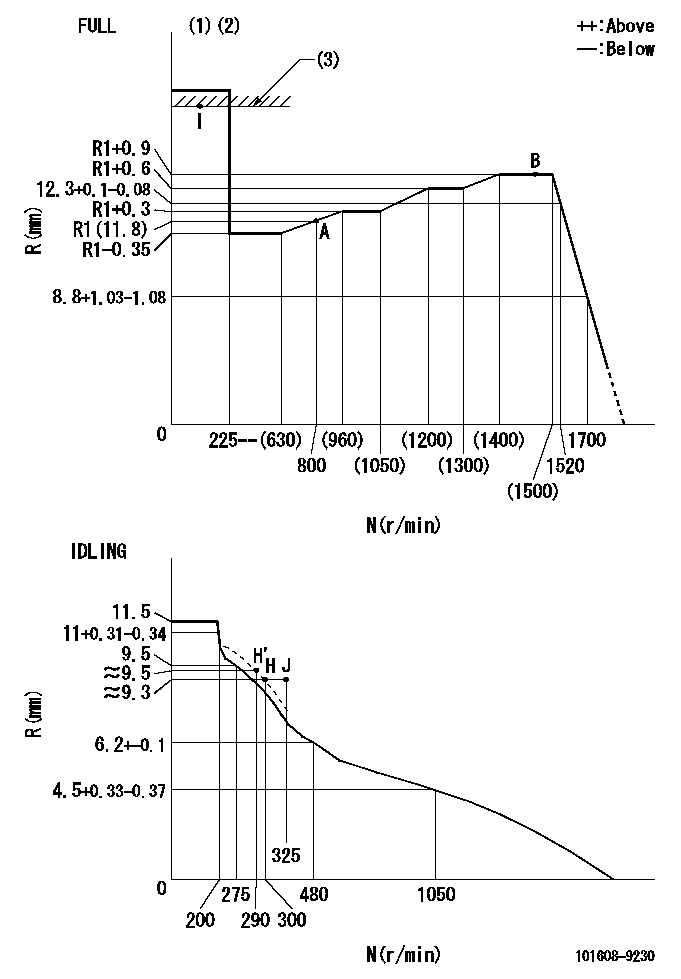

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=L85

----------

----------

T1=L85

----------

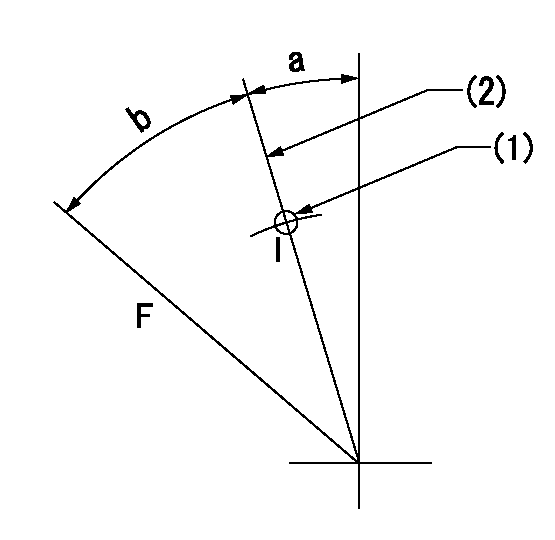

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=38mm

----------

a=6.5deg+-5deg b=35deg+-3deg

----------

aa=38mm

----------

a=6.5deg+-5deg b=35deg+-3deg

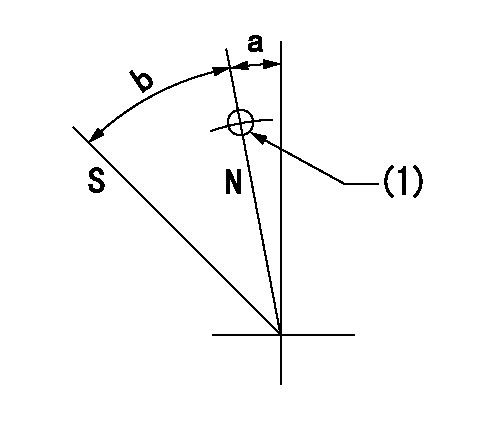

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=5deg+-5deg b=40deg+-5deg

----------

aa=42mm

----------

a=5deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

GENERAL

Specifications

Construction

Cooling System Component Parts(1) Cooling fan(2) Water pump pulley(3) Water pump assembly(4) V-belt(5) Thermostat(6) Thermostat fitting(7) Thermoswitch(8) Bypass pipeFAN AND FAN BELT

Fan Belt Inspection

For fan belt tension, see 0-06 MAINTENANCE.

Inspecting Fan BeltFan Inspection

Check the fan for cracks, damaged and deformation. If any, replace the fan.

Inspecting FanWATER PUMP

Removal and Installation

(1) Remove the fan and fan belt.(2) Remove the water pump.(3) When installing the water pump, reverse the above-mentioned order of removal.

Removing Water PumpInspection

Check the water pump for water leak, rough rotation, and cracks. If any, replace the water pump assembly.THERMOSTAT

Removal and Installation

Pay attention to the following:(1) Never allow the flange to protrude from the faucet joint.(2) Renew the gasket.

Installing ThermostatInspection

If the thermostat does not operate properly, replace it.

Inspecting Thermostat WATER TEMPERATURE GAUGE UNIT AND THERMOSWITCH

Inspection of Water Temperature Gauge Unit

If the gauge does not function properly, replace it.

Inspecting Temperature Gauge Unit CAUTION Handle hot oil with special care not to cause a scald or a fire.Inspection of Thermoswitch

Inspecting Thermoswitch CAUTION Handle hot oil with special care not to cause a scald or a fire.

Specifications

Construction

Cooling System Component Parts(1) Cooling fan(2) Water pump pulley(3) Water pump assembly(4) V-belt(5) Thermostat(6) Thermostat fitting(7) Thermoswitch(8) Bypass pipeFAN AND FAN BELT

Fan Belt Inspection

For fan belt tension, see 0-06 MAINTENANCE.

Inspecting Fan BeltFan Inspection

Check the fan for cracks, damaged and deformation. If any, replace the fan.

Inspecting FanWATER PUMP

Removal and Installation

(1) Remove the fan and fan belt.(2) Remove the water pump.(3) When installing the water pump, reverse the above-mentioned order of removal.

Removing Water PumpInspection

Check the water pump for water leak, rough rotation, and cracks. If any, replace the water pump assembly.THERMOSTAT

Removal and Installation

Pay attention to the following:(1) Never allow the flange to protrude from the faucet joint.(2) Renew the gasket.

Installing ThermostatInspection

If the thermostat does not operate properly, replace it.

Inspecting Thermostat WATER TEMPERATURE GAUGE UNIT AND THERMOSWITCH

Inspection of Water Temperature Gauge Unit

If the gauge does not function properly, replace it.

Inspecting Temperature Gauge Unit CAUTION Handle hot oil with special care not to cause a scald or a fire.Inspection of Thermoswitch

Inspecting Thermoswitch CAUTION Handle hot oil with special care not to cause a scald or a fire.