Information injection-pump assembly

ZEXEL

101608-9220

1016089220

NISSAN-DIESEL

16713Z6664

16713z6664

Rating:

Cross reference number

ZEXEL

101608-9220

1016089220

NISSAN-DIESEL

16713Z6664

16713z6664

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8260

Bosch type code

9 430 610 133

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131425-0420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.7

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

92

90.4

93.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

265

265

265

Average injection quantity

mm3/st.

9

7.2

10.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.7)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

92

91

93

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.95

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

97.5

93.5

101.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1-0.35

)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

86.5

82.5

90.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

150

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

(900)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1080

Advance angle

deg.

2

1.5

2.5

Timer adjustment_03

Pump speed

r/min

1225

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

1425

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

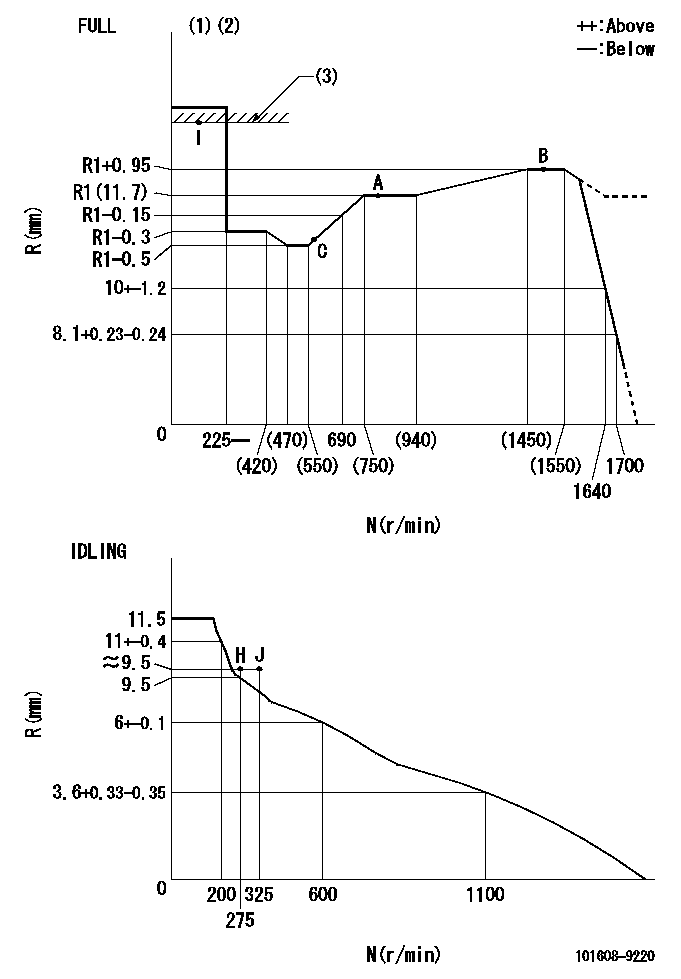

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=L95

----------

----------

T1=L95

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=100mm

----------

a=26.5deg+-5deg b=(46deg)+-3deg

----------

aa=100mm

----------

a=26.5deg+-5deg b=(46deg)+-3deg

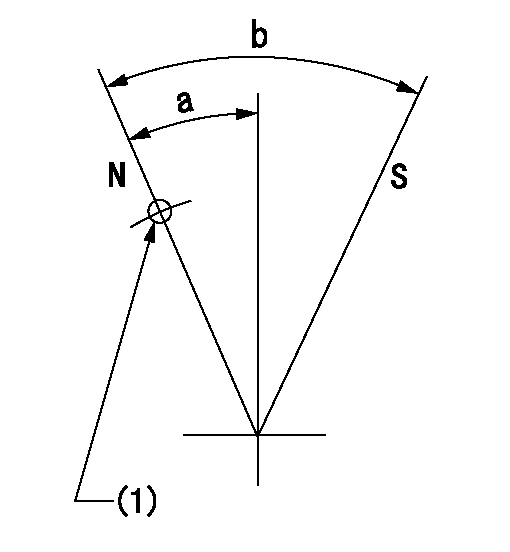

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

----------

aa=42mm

----------

a=25deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

GENERAL

Specification

Construction

Governor System Component Parts(1) Sealing metal(2) Sealing wire(3) Low- and high-speed(4) Governor spring(5) Sliding shaft(6) Stopper(7) Governor spring(8) Governor shaft(9) Governor lever(10) Tie-rod(11) Tie-rod clip(12) Tie-rod cover(13) tie-rod cover gasket(14) Tension lever(15) Start spring(16) Governor spring lever(17) Speed control lever assembly(18) Cover assembly(19) Governor cover gasket(20) Return spring(21) Stop lever assembly(22) O-ring(23) Snap ring(24) Stop lever(25) Grooved pin (3 x 20)(26) Grooved pin (3 x 14)(27) Torque spring set(28) Sealing capTORQUE SPRING

Installation of Torque Spring Set

Install and adjust the torque spring set using the following procedure:(1) Set the speed control lever to the high-idling speed position by adjusting the high-speed set bolt.(2) Turn in the torque spring set until engine speed drops about 50 rpm from high-idling speed.(3) From this position, turn back the torque spring set by the specified number of turns (N.) Lock the torque spring set at that position with the special nut.(4) Install the torque spring set sealing cap and stake the cap to prevent loosening. CAUTION There are two types of torque spring set: The single spring type and the double-spring type. Since each torque spring set has been adjusted precisely during assembly, do not tamper with the adjust screw unless it is necessary.

Torque spring setAssembling the Torque Spring Set

When the torque spring set has been disassembled or its component parts have been replaced, reassemble and adjust the torque spring set using the following procedure:

Assembling torque spring setSingle spring type

When installing the single-spring type torque spring set, use the following steps.(1) Lightly turn in adjust screw (5) (with a screw-driver operated by fingertips) until a resistance to screw rotation is felt. Lightly lock the screw at that position with locknut (4).(2) Set the scale to the zero-point. Turn in the spring case (2) until the value of load "A" shown in table below can be attained. Lock the spring case at that position with special nut (3).(3) Temporarily loosen adjust screw (5) until the value of load "A" is reduced by about 200 grams, and then retighten the screw until the value of "B" is attained. Lock the screw at that position with locknut (4).Adjust screw tightening torque: 0.8 to 1.2 kg.(4) To inspect the torque spring set for properly adjusted spring load, use a testing arrangement such as shown in the figure at right. Gradually push the scale against the torque spring set until the stopper (1) is moved (or the pointer of dial gauge deflects). Check that the load applied to the torque spring at that moment coincides with the value of load "C".

Setting of Torque Spring CHECKING

Replace the gear case and inspect the governor. When removing the gear case, be sure to remove the tie-rod cover by the side of the fuel pump and disconnect the tie-rod from the rack.If any parts are found defective, replace them.

Inspecting Torque Spring CAUTION When the governor is assumed to be malfunctioning, check the bearing on the gear case side, too.

Inspection Governor System PartsRemoval and Installation

(Refer to I-06 GEAR CASE AND OIL PUMP.)Removal(1) Removing

Specification

Construction

Governor System Component Parts(1) Sealing metal(2) Sealing wire(3) Low- and high-speed(4) Governor spring(5) Sliding shaft(6) Stopper(7) Governor spring(8) Governor shaft(9) Governor lever(10) Tie-rod(11) Tie-rod clip(12) Tie-rod cover(13) tie-rod cover gasket(14) Tension lever(15) Start spring(16) Governor spring lever(17) Speed control lever assembly(18) Cover assembly(19) Governor cover gasket(20) Return spring(21) Stop lever assembly(22) O-ring(23) Snap ring(24) Stop lever(25) Grooved pin (3 x 20)(26) Grooved pin (3 x 14)(27) Torque spring set(28) Sealing capTORQUE SPRING

Installation of Torque Spring Set

Install and adjust the torque spring set using the following procedure:(1) Set the speed control lever to the high-idling speed position by adjusting the high-speed set bolt.(2) Turn in the torque spring set until engine speed drops about 50 rpm from high-idling speed.(3) From this position, turn back the torque spring set by the specified number of turns (N.) Lock the torque spring set at that position with the special nut.(4) Install the torque spring set sealing cap and stake the cap to prevent loosening. CAUTION There are two types of torque spring set: The single spring type and the double-spring type. Since each torque spring set has been adjusted precisely during assembly, do not tamper with the adjust screw unless it is necessary.

Torque spring setAssembling the Torque Spring Set

When the torque spring set has been disassembled or its component parts have been replaced, reassemble and adjust the torque spring set using the following procedure:

Assembling torque spring setSingle spring type

When installing the single-spring type torque spring set, use the following steps.(1) Lightly turn in adjust screw (5) (with a screw-driver operated by fingertips) until a resistance to screw rotation is felt. Lightly lock the screw at that position with locknut (4).(2) Set the scale to the zero-point. Turn in the spring case (2) until the value of load "A" shown in table below can be attained. Lock the spring case at that position with special nut (3).(3) Temporarily loosen adjust screw (5) until the value of load "A" is reduced by about 200 grams, and then retighten the screw until the value of "B" is attained. Lock the screw at that position with locknut (4).Adjust screw tightening torque: 0.8 to 1.2 kg.(4) To inspect the torque spring set for properly adjusted spring load, use a testing arrangement such as shown in the figure at right. Gradually push the scale against the torque spring set until the stopper (1) is moved (or the pointer of dial gauge deflects). Check that the load applied to the torque spring at that moment coincides with the value of load "C".

Setting of Torque Spring CHECKING

Replace the gear case and inspect the governor. When removing the gear case, be sure to remove the tie-rod cover by the side of the fuel pump and disconnect the tie-rod from the rack.If any parts are found defective, replace them.

Inspecting Torque Spring CAUTION When the governor is assumed to be malfunctioning, check the bearing on the gear case side, too.

Inspection Governor System PartsRemoval and Installation

(Refer to I-06 GEAR CASE AND OIL PUMP.)Removal(1) Removing