Information injection-pump assembly

BOSCH

F 01G 09U 064

f01g09u064

ZEXEL

101608-9150

1016089150

NISSAN-DIESEL

1671395302

1671395302

Rating:

Include in #2:

105856-2520

as _

Cross reference number

BOSCH

F 01G 09U 064

f01g09u064

ZEXEL

101608-9150

1016089150

NISSAN-DIESEL

1671395302

1671395302

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

13.8

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

118

116.4

119.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.6+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

9

7.2

10.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.8)

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

118

117

119

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

94.5

91.3

97.7

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2-0.75

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

60.5

56.5

64.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

80

80

100

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R2-0.75

Boost pressure

kPa

7.3

6

8.6

Boost pressure

mmHg

55

45

65

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R2(R1-1.

2)

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

920--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

870

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

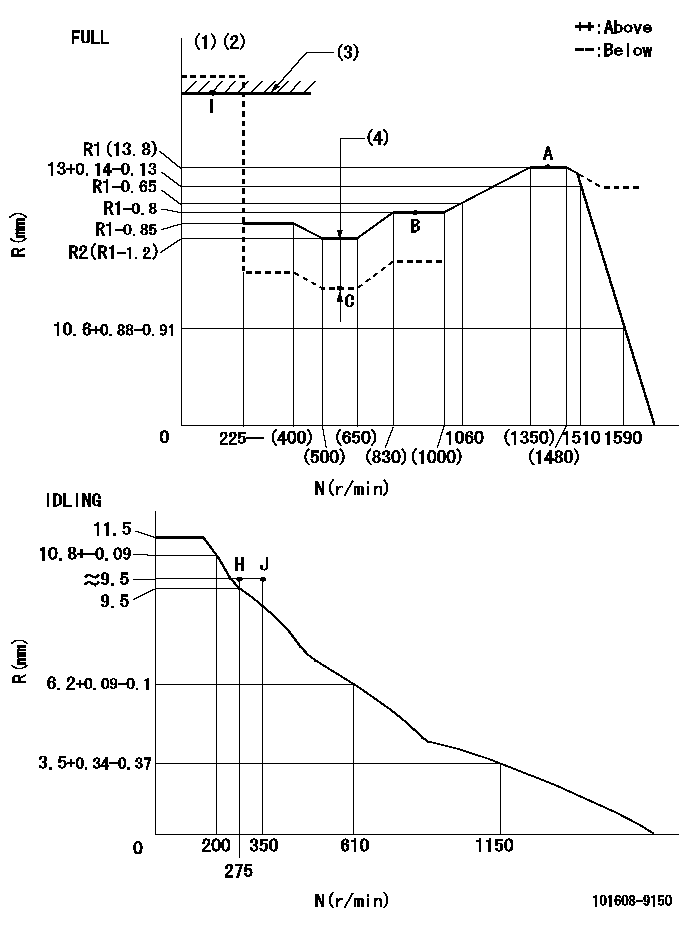

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=J98 BCL=0.75+-0.1mm

----------

----------

T1=J98 BCL=0.75+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=100mm

----------

a=26.5deg+-5deg b=42deg+-3deg

----------

aa=100mm

----------

a=26.5deg+-5deg b=42deg+-3deg

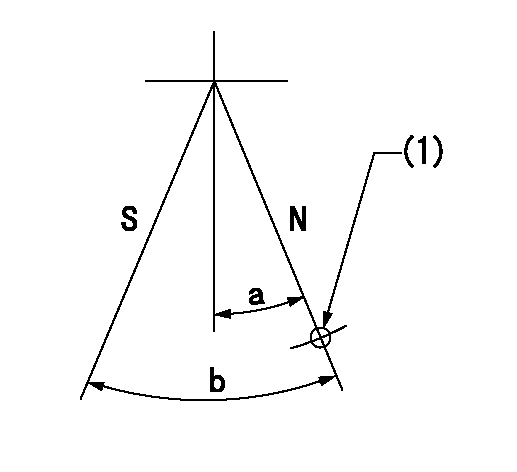

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=36mm

----------

a=20deg+-5deg b=40deg+-5deg

----------

aa=36mm

----------

a=20deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

No-load testAlternator

If a problem occurs in the charge system, check the following conditions to locate the cause of the problem. Only when inspection cannot be conducted on the alternator in the installed condition, dismount the alternator for inspection and repair. On Vehicle Inspection

(1) Cautions for handlingHandle the alternator carefully, as incorrect handling can result in alternator damage or malfunctions.(a) Do not connect the battery cables in reverse. Note the negative (-) cable is a grounding wire.(b) Do not use a high-voltage tester such as a megger.(c) When charging the battery, disconnect the cables from the battery terminals.(d) Do not disconnect the lead wire from terminal B of the alternator while the engine is operating.(e) Do not ground terminal B of the alternator since it is constantly applied with battery voltage.(f) Do not short-circuit or ground terminal L. (unit with integrated IC regulator)(g) When using a steam cleaner, do not allow steam to directly contact the alternator.(2) Inspection of adjustment voltage (unit with integrated IC regulator)(a) Disconnect the cable from the positive (+) terminal of the battery, and connect an ammeter between the terminal and cable.(b) Connect a voltmeter between terminal L and ground.(c) Make sure that the voltmeter indicates "0" when the starter switch is turned off. Make sure that the voltmeter indicates a voltage level significantly lower than the battery voltage when the starter switch is turned on (without starting the engine).(d) Short-circuit the terminal of the ammeter, and start the engine.(e) Read the indication (adjustment voltage) on the voltmeter with the ammeter indicating 5A or lower, the engine operating at 1500 to 2500 min-1, and the lamp switches turned off.

Inspection of adjustment voltage (3) Inspection of output (unit with integrated IC regulator)(a) Disconnect the grounding cable from the battery.(b) Disconnect the wire from terminal B of the alternator, and connect an ammeter, then connect a voltmeter between B and ground.(c) Reconnect the grounding cable to the battery.(d) Start the engine.(e) Immediately after the engine starts, turn on all load devices such as lamps.(f) Increase the engine speed, and read the maximum current at the specified alternator rotation speed when the voltmeter indicates 27.0 V. If the measured value conforms to the standard value, the alternator is normal.

Wiring for output test (unit with integrated IC regulator) Disassembly of Alternator

(1) Separation of front bracket from stator coreInsert the tip of a slotted screwdriver into the gap between the stator core and front bracket, and pry open.

Do not insert the screwdriver too far into the assembly to prevent damaging the stator core.

Separation of front bracket from stator core(2) Removal of pulley(a) After wrapping the rotor with a cloth for protection and holding it with a vice, unscrew the pulley nut, then remove the pulley and spacer.(b) Remove the rotor from the front bracket.

Removal of pulley(3) Removal of stator core and rectifier(a) Disconnect the lead wires between the stator core and the rectifier at the soldered sections, and remove the stator core.

Melt the soldered sections as quickly as possible. Prolonged