Information injection-pump assembly

BOSCH

9 400 619 512

9400619512

ZEXEL

101608-6431

1016086431

Rating:

Service parts 101608-6431 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Include in #1:

101608-6431

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-0842

as _

Cross reference number

BOSCH

9 400 619 512

9400619512

ZEXEL

101608-6431

1016086431

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED4 control unit part number

407915-0

590

RED4 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Rack position

(11.1)

PWM

%

50.4

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

124.5

123.5

125.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Injection quantity adjustment_02

Rack position

(7.3)

PWM

%

29.4+-2.

8

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

11

9.5

12.5

Max. variation between cylinders

%

0

-15

15

Governor adjustment

Pump speed

r/min

600

Advance angle

deg.

3

2.5

3.5

Load

0/4

Remarks

Start

Start

Governor adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Load

0/4

Governor adjustment_03

Pump speed

r/min

(850)

Advance angle

deg.

0

0

0

Load

4/4

Remarks

Measure the actual speed.

Measure the actual speed.

Governor adjustment_04

Pump speed

r/min

1075

Advance angle

deg.

1.5

1

2

Load

4/4

Remarks

Finish

Finish

Test data Ex:

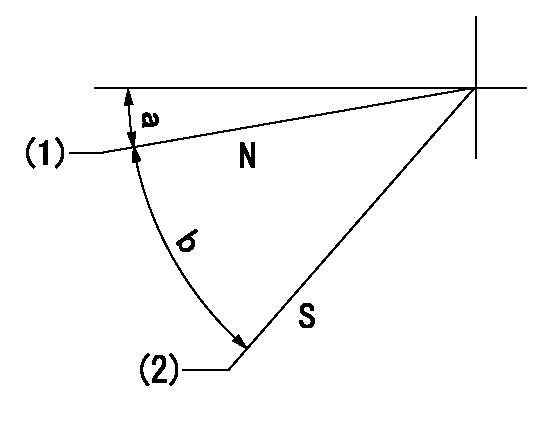

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=5deg+-5deg b=37deg+-5deg

----------

aa=20mm bb=1mm

----------

a=5deg+-5deg b=37deg+-5deg

0000000901

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=8deg

----------

a=(4deg)

----------

aa=8deg

----------

a=(4deg)

Stop lever angle

(PWM) Pulse width modulation (%)

(R) Rack position (mm)

Rack sensor output characteristics

1. Rack limit adjustment

(1)Measure the rack position R2 for PWM a2%.

(2)Confirm that it is within the range R2 = 15+-1 mm.

(3)Measure the rack position R1 at PWM a %.

(4)Confirm that it is within the range R2 - R1 = 10+-0.1 mm.

2. Check the limp home operation.

(1)Move the switch box's limp home switch to the limp home side.

(2)Confirm rack position L1 (mm ) and L2 (mm) for PWM in the above table.

3. Check the pull down operation.

(1)Confirm that the rack position is 19 mm at PWM B%.

(2)In the conditions described in the above table, move the switch box's pull down switch to the pull down side and confirm that the rack position momentarily becomes 1 mm or less.

----------

a1=16.25% a2=72.5% L1=1--mm L2=19++mm A=5% B=95%

----------

----------

a1=16.25% a2=72.5% L1=1--mm L2=19++mm A=5% B=95%

----------

Information:

1. Determining Overhaul Timing

The timing of engine overhauls should be determined primarily in accordance with reductions in compression pressure. A reduction in compression pressure may be accompanied by one or more of the following externally observable symptoms:(a) Reduced power(b) Increased fuel consumption(c) Increased engine-oil consumption(d) Increased blowby gas through breather (possibly owing to wear on cylinder liners and piston rings)(e) Gas leakage (possibly owing to poor seating of intake and exhaust valves)(f) Starting problems(g) Increased engine noise(h) Abnormal exhaust-gas color after engine warmupAlthough these symptoms can be caused by a reduction in compression pressure, they can be caused also by other problems that are not related to engine deterioration. Notably, symptoms (b) and (f) may be affected significantly by the injection pump's injection rate, by the injection timing, by plunger wear, by injector defects, and/or by the battery, starter, and other electrical equipment. Symptoms (d) should be given special attention since a decrease in compression pressure owing to wear on the cylinder liners and piston rings is one of the most obvious signs that the engine needs an overhaul. It is essential, however, to measure the compression pressure in each cylinder and to use the results as the primary criteria for making a decision to overhaul the engine.2. Measuring Compression Pressure

2.1 Preparation for InspectionPerform the following checks before starting the inspection.(1) Make sure the engine oil, air cleaner, starter, and battery are normal.(2) Make sure the engine is warm.2.2 Inspection(1) Move the control lever to the stop position.(2) Remove all glow plugs, then connect the Compression Gauge Adapter (ST333060) and compression gauge to the cylinder whose compression pressure is to be checked.(3) Crank the engine using the starter until the needle of the compression gauge stops moving, then read the pressure indication.(4) If the measurement is lower than the specified limit, perform an overhaul.

(a) Measure the compression pressure of every cylinder. Measuring the compression pressures of two or three cylinders and simply assuming the compression pressures of the other cylinders is dangerous.(b) The compression pressure varies with the engine speed, so it is important to take all measurements with the same engine speed.

Unit: MPa {kgf/cm2} (psi) Take measurements with an engine speed of 240 min-1.

Compression gauge and adapter

Measuring compression pressure

(a) It is important to measure compression pressures regularly and to keep track of changes in them.(b) During the engine's run-in period and after an overhaul, the compression pressures will increase slightly as the piston rings, valve seats, and other parts fit snugly in position. The pressures will then decrease as parts wear.

3. Troubleshooting

3.1 OverviewDiesel-engine fault symptoms tend to have multiple causes, which influence each other. Consequently, it is often difficult to locate a fault based on the symptoms. Particular care is required when diagnosing faults related to the injection pump, injectors, and compression pressures since such faults may produce the same symptoms.For the above-mentioned reasons, the inspection sequences in the troubleshooting charts on the following pages start with items where the likelihood of a fault is greatest with

The timing of engine overhauls should be determined primarily in accordance with reductions in compression pressure. A reduction in compression pressure may be accompanied by one or more of the following externally observable symptoms:(a) Reduced power(b) Increased fuel consumption(c) Increased engine-oil consumption(d) Increased blowby gas through breather (possibly owing to wear on cylinder liners and piston rings)(e) Gas leakage (possibly owing to poor seating of intake and exhaust valves)(f) Starting problems(g) Increased engine noise(h) Abnormal exhaust-gas color after engine warmupAlthough these symptoms can be caused by a reduction in compression pressure, they can be caused also by other problems that are not related to engine deterioration. Notably, symptoms (b) and (f) may be affected significantly by the injection pump's injection rate, by the injection timing, by plunger wear, by injector defects, and/or by the battery, starter, and other electrical equipment. Symptoms (d) should be given special attention since a decrease in compression pressure owing to wear on the cylinder liners and piston rings is one of the most obvious signs that the engine needs an overhaul. It is essential, however, to measure the compression pressure in each cylinder and to use the results as the primary criteria for making a decision to overhaul the engine.2. Measuring Compression Pressure

2.1 Preparation for InspectionPerform the following checks before starting the inspection.(1) Make sure the engine oil, air cleaner, starter, and battery are normal.(2) Make sure the engine is warm.2.2 Inspection(1) Move the control lever to the stop position.(2) Remove all glow plugs, then connect the Compression Gauge Adapter (ST333060) and compression gauge to the cylinder whose compression pressure is to be checked.(3) Crank the engine using the starter until the needle of the compression gauge stops moving, then read the pressure indication.(4) If the measurement is lower than the specified limit, perform an overhaul.

(a) Measure the compression pressure of every cylinder. Measuring the compression pressures of two or three cylinders and simply assuming the compression pressures of the other cylinders is dangerous.(b) The compression pressure varies with the engine speed, so it is important to take all measurements with the same engine speed.

Unit: MPa {kgf/cm2} (psi) Take measurements with an engine speed of 240 min-1.

Compression gauge and adapter

Measuring compression pressure

(a) It is important to measure compression pressures regularly and to keep track of changes in them.(b) During the engine's run-in period and after an overhaul, the compression pressures will increase slightly as the piston rings, valve seats, and other parts fit snugly in position. The pressures will then decrease as parts wear.

3. Troubleshooting

3.1 OverviewDiesel-engine fault symptoms tend to have multiple causes, which influence each other. Consequently, it is often difficult to locate a fault based on the symptoms. Particular care is required when diagnosing faults related to the injection pump, injectors, and compression pressures since such faults may produce the same symptoms.For the above-mentioned reasons, the inspection sequences in the troubleshooting charts on the following pages start with items where the likelihood of a fault is greatest with