Information injection-pump assembly

BOSCH

9 400 615 854

9400615854

ZEXEL

101608-6412

1016086412

MITSUBISHI

ME441215

me441215

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump ME441215 ME441044 for Mitsubishi Engine 6D34T 6D34 Kobelco Excavator SK200-3 SK200-6

100% Apollo part number:ME441215 ME441044 || application: for Mitsubishi Engine 6D34T 6D34 Kobelco Excavator SK200-3 SK200-6

100% Apollo part number:ME441215 ME441044 || application: for Mitsubishi Engine 6D34T 6D34 Kobelco Excavator SK200-3 SK200-6

YANNAL PART 1 PC Fuel Injection Pump ME441215 101608-6412 Suitable for Mitsubishi 6D34 Engine Part

YANNAL PART Product Name: Fuel Injection Pump || Part Number: ME441215 101608-6412 || Application: Compatible for Mitsubishi 6D34 || Warranty: 1 Year || Note: Please verify your part number before ordering, any problem please feel free to contact us, thanks.

YANNAL PART Product Name: Fuel Injection Pump || Part Number: ME441215 101608-6412 || Application: Compatible for Mitsubishi 6D34 || Warranty: 1 Year || Note: Please verify your part number before ordering, any problem please feel free to contact us, thanks.

Fuel Injection Pump 101608-6412 Compatible with Kobelco 6D34T 6D34 Engine SK200-3 SK200-6

Starhycfa Product name:Fuel Injection Pump || Part Number:101608-6412 1016086412 || APPlication:Compatible with Kobelco 6D34T 6D34 Engine SK200-3 SK200-6 || 1.Please carefully compare the pictures or OE numbers to match your original parts beCompatible withe purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours beCompatible withe order. To Avoid placing wrong orders and wasting your precious time.

Starhycfa Product name:Fuel Injection Pump || Part Number:101608-6412 1016086412 || APPlication:Compatible with Kobelco 6D34T 6D34 Engine SK200-3 SK200-6 || 1.Please carefully compare the pictures or OE numbers to match your original parts beCompatible withe purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours beCompatible withe order. To Avoid placing wrong orders and wasting your precious time.

You can express buy:

Images:

USD 2375.62

[01-Nov-2022]

Service parts 101608-6412 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME440837

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

101608-6412

as INJECTION-PUMP ASSEMBLY

Include in #2:

104740-0830

as _

Cross reference number

BOSCH

9 400 615 854

9400615854

ZEXEL

101608-6412

1016086412

MITSUBISHI

ME441215

me441215

Zexel num

Bosch num

Firm num

Name

101608-6412

9 400 615 854

ME441215 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D34TL K 14BE INJECTION PUMP ASSY PE6A PE

6D34TL K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

103

102

104

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

66.7

66.7

Boost pressure

mmHg

500

500

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.2+-0.5

Pump speed

r/min

475

475

475

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

9.1++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

65

70

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

750

750

750

Rack position

R1-1.3

Boost pressure

kPa

10.7

8

13.4

Boost pressure

mmHg

80

60

100

Boost compensator adjustment_02

Pump speed

r/min

750

750

750

Rack position

R1(8.9)

Boost pressure

kPa

57.3

50.6

64

Boost pressure

mmHg

430

380

480

Timer adjustment

Pump speed

r/min

0

Advance angle

deg.

3

2

3

Load

0/4

Timer adjustment_02

Pump speed

r/min

650+-25

Advance angle

deg.

3

2

3

Load

0/4

Remarks

Start

Start

Timer adjustment_03

Pump speed

r/min

750+-25

Advance angle

deg.

0

0

0

Load

0/4

Remarks

Finish

Finish

Test data Ex:

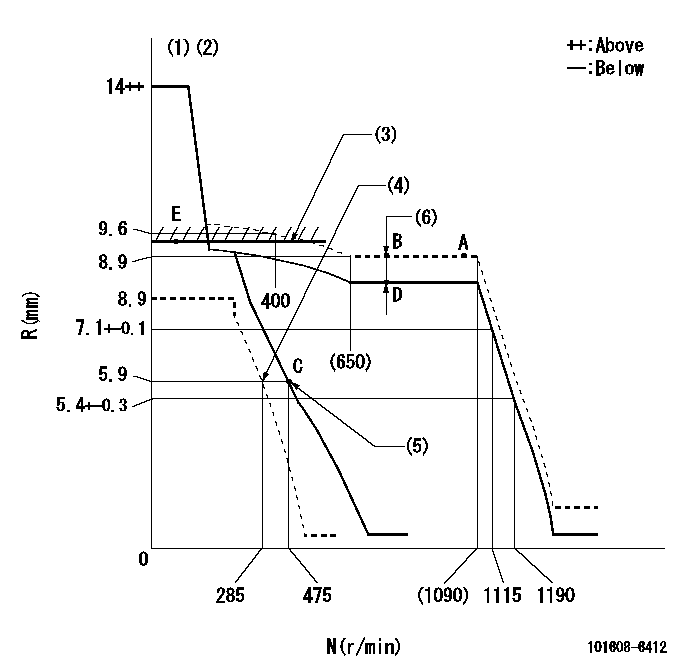

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

----------

K=19 BCL=1.3+-0.1mm

----------

----------

K=19 BCL=1.3+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=12deg+-5deg b=19deg+-5deg

----------

----------

a=12deg+-5deg b=19deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

(2)Normal

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=21deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(130deg)

----------

aa=10deg

----------

a=(130deg)

Information:

GENERAL

1. Schematic

Schematic2. Specifications INSPECTION

1. Oil pumpVisually check the pump for rough rotation or other defects. Replace the pump assembly if defective.

Checking oil pump2. Oil pressure switch (1) Test for continuity between the terminal and body with an ohmmeter as shown in the illustration. No continuity is the cause for replacing the switch.

Testing oil pressure switch (1)(2) Insert a small diameter bar into the oil hole in the switch and lightly push it in to test for no continuity as shown in the illustration. Any continuity is the cause for replacing the switch.(3) Apply a pressure air of 0.5 kgf/cm2 (7 psi) [49 kPa] to the switch through the oil hole to test for no continuity. Any continuity is the cause for replacing the switch. Also, check for air leaks. Any air leak is an indication of a ruptured diaphragm. In such a case, replace the switch.

Testing oil pressure switch (2)3. Pressure relief valve (1) Check the valve seat for contact. Check the spring for damage.(2) Measure the oil pressure at which the relief valve opens (the oil pressure with the engine running at the rated rpm). If the pressure is not correct, remove the cap nut and increase or decrease the amount of shims. The engine oil pressure tap is located on the right side of the engine.

Checking pressure relief valve

1. Schematic

Schematic2. Specifications INSPECTION

1. Oil pumpVisually check the pump for rough rotation or other defects. Replace the pump assembly if defective.

Checking oil pump2. Oil pressure switch (1) Test for continuity between the terminal and body with an ohmmeter as shown in the illustration. No continuity is the cause for replacing the switch.

Testing oil pressure switch (1)(2) Insert a small diameter bar into the oil hole in the switch and lightly push it in to test for no continuity as shown in the illustration. Any continuity is the cause for replacing the switch.(3) Apply a pressure air of 0.5 kgf/cm2 (7 psi) [49 kPa] to the switch through the oil hole to test for no continuity. Any continuity is the cause for replacing the switch. Also, check for air leaks. Any air leak is an indication of a ruptured diaphragm. In such a case, replace the switch.

Testing oil pressure switch (2)3. Pressure relief valve (1) Check the valve seat for contact. Check the spring for damage.(2) Measure the oil pressure at which the relief valve opens (the oil pressure with the engine running at the rated rpm). If the pressure is not correct, remove the cap nut and increase or decrease the amount of shims. The engine oil pressure tap is located on the right side of the engine.

Checking pressure relief valve

Have questions with 101608-6412?

Group cross 101608-6412 ZEXEL

Mitsubishi

Mitsubishi

101608-6412

9 400 615 854

ME441215

INJECTION-PUMP ASSEMBLY

6D34TL

6D34TL