Information injection-pump assembly

BOSCH

F 019 Z20 018

f019z20018

ZEXEL

101608-6292

1016086292

MITSUBISHI

ME440070

me440070

Rating:

Service parts 101608-6292 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)

15.

NOZZLE SET

Include in #1:

101608-6292

as INJECTION-PUMP ASSEMBLY

Include in #2:

104748-0482

as _

Cross reference number

BOSCH

F 019 Z20 018

f019z20018

ZEXEL

101608-6292

1016086292

MITSUBISHI

ME440070

me440070

Zexel num

Bosch num

Firm num

Name

101608-6292

F 019 Z20 018

ME440070 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D16TL K 14BN INJECTION PUMP ASSY PE

6D16TL K 14BN INJECTION PUMP ASSY PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.5

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

116

115

117

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

54.7

54.7

Boost pressure

mmHg

410

410

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.1+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

8.5

7

10

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

11.7++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

95

105

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

9.5

Boost pressure

kPa

15.3

8.6

22

Boost pressure

mmHg

115

65

165

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

10.7

Boost pressure

kPa

45.3

42.6

48

Boost pressure

mmHg

340

320

360

Timer adjustment

Pump speed

r/min

1070--

Advance angle

deg.

0

0

0

Load

4/4

Remarks

Beginning of advance.

Beginning of advance.

Timer adjustment_02

Pump speed

r/min

440

Advance angle

deg.

3

2.5

3.5

Load

0/4

Remarks

Start

Start

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Load

0/4

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1020

Advance angle

deg.

0.5

Load

4/4

Timer adjustment_05

Pump speed

r/min

1330

Advance angle

deg.

3

2.5

3.5

Load

4/4

Remarks

Finish

Finish

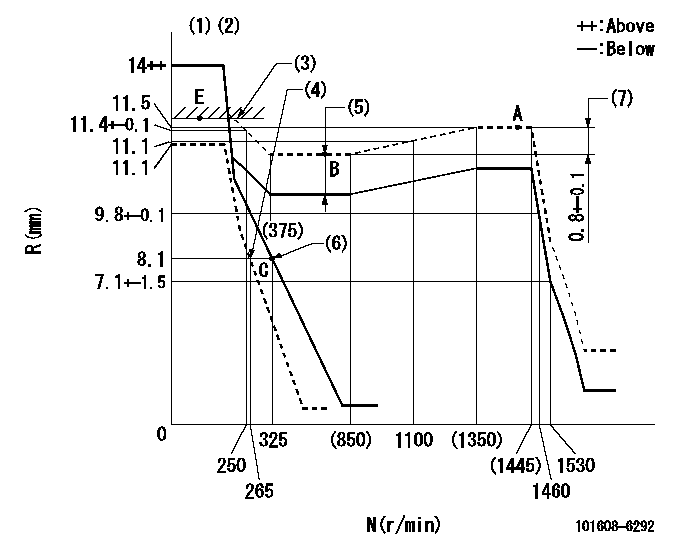

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Boost compensator stroke: BCL

(6)Main spring setting

(7)Rack difference between N = N1 and N = N2

----------

K=11 BCL=1.2+-0.1mm N1=1400r/min N2=650r/min

----------

----------

K=11 BCL=1.2+-0.1mm N1=1400r/min N2=650r/min

----------

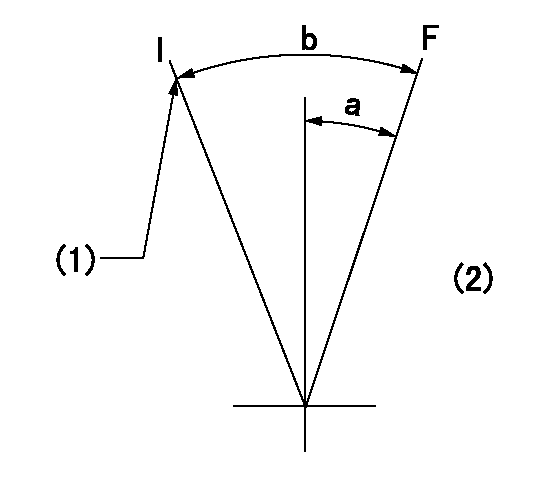

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Base lever only

----------

----------

a=(17deg)+-5deg b=(34deg)+-5deg

----------

----------

a=(17deg)+-5deg b=(34deg)+-5deg

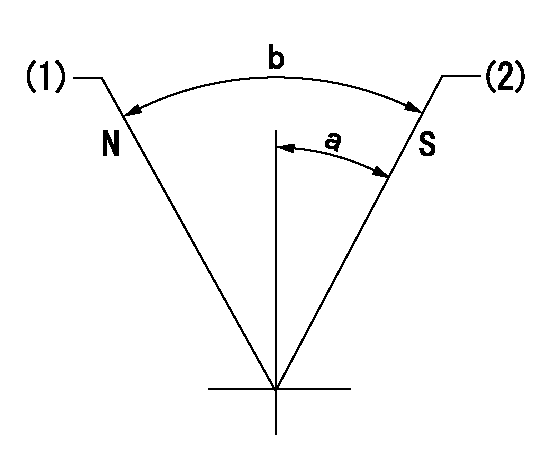

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=4-0.5mm

----------

a=28deg+-5deg b=(48deg)

----------

aa=0r/min bb=4-0.5mm

----------

a=28deg+-5deg b=(48deg)

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=6.5deg

----------

a=(3deg)

----------

aa=6.5deg

----------

a=(3deg)

Information:

AFFECTED PRODUCT

Model Identification Number

D6R III GMT00101-00170

HCD00123-00155

TBC00100-00191

D6R III LGP DMK00130-00208

JWD00250

LGP00164-00166

WRG00158-00564

D6R III XL GJB00173-00622

JDL00113-00202

LAE00125

LFM00111-00180

D6R III XW DPS00120-00132

MRT00163-00387

D6R IIIP LGP DLM00161-00162

WCB00112-00184

D6R IIIP XL HKE00146-00221

RFC00140

D6R IIIP XW DJG00250-00251

HDC00133-00211

MTJ00151-00152

PARTS NEEDED

No parts needed for this program

ACTION REQUIRED

Please refer to the attached Rework Procedure.

OWNER NOTIFICATION

U.S. and Canadian owners will receive the attached Owner Notification.

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 1.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR FLASHING INJECTOR ETRIM FILES

MODELS INVOLVED - CERTAIN D6R III, D6R IIIP XW, D6R IIIP LGP, D6R III LGP, D6R III XW, AND D6R III XL TRACK TYPE TRACTORS

Dear Caterpillar Product Owner:

New injector etrim files need to be installed on the products listed below. The upgraded files will help performance and stability of your D6R engine. You will not be charged for the service performed.

Contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

Please refer the dealer to their Service Letter dated 31Aug2006 when scheduling this service.

We regret the inconvenience this may cause you, but urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 31Aug2006 Service Letter

Rework Procedure

Field Rework Procedure

1. Using the provided machine serial number of the D6R Series III tractor in your service area, go to TMI web and look up the engine serial number.

2. Look up your engine serial number on the Excell file emailed to all machine TCs in order to access the injector serial numbers. If you don't have a copy of this file go the the Knowledge Network to get the file from the following web address: https://kn.cat.com/message.cfm?id=4388&parent=153301&type=Broadcast

3. Copy the 6 injector serial numbers for each machine in your service area and go to SIS web.

4. At the main menu click on Service Software Files.

5. Follow the directions and down load the trim file for each injector, putting them on a disk or in a file that can be accessed from ET.

6. Down load the six trim files for the injectors and program into the ECM in the correct order, using ET.

7. Make sure the machine SN and /or engine SN are included in the service letter claim

Have questions with 101608-6292?

Group cross 101608-6292 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

101608-6292

F 019 Z20 018

ME440070

INJECTION-PUMP ASSEMBLY

6D16TL

6D16TL