Information injection-pump assembly

ZEXEL

101608-6141

1016086141

Rating:

Cross reference number

ZEXEL

101608-6141

1016086141

Zexel num

Bosch num

Firm num

Name

101608-6141

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

108

107

109

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

50.7

50.7

Boost pressure

mmHg

380

380

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.6+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

9.5

8

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

120

110

130

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

R1-0.7

Boost pressure

kPa

22.7

20

25.4

Boost pressure

mmHg

170

150

190

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

R1(10.6)

Boost pressure

kPa

37.3

30.6

44

Boost pressure

mmHg

280

230

330

Timer adjustment

Pump speed

r/min

1100++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1100.

Do not advance until starting N = 1100.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

4

4

4

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

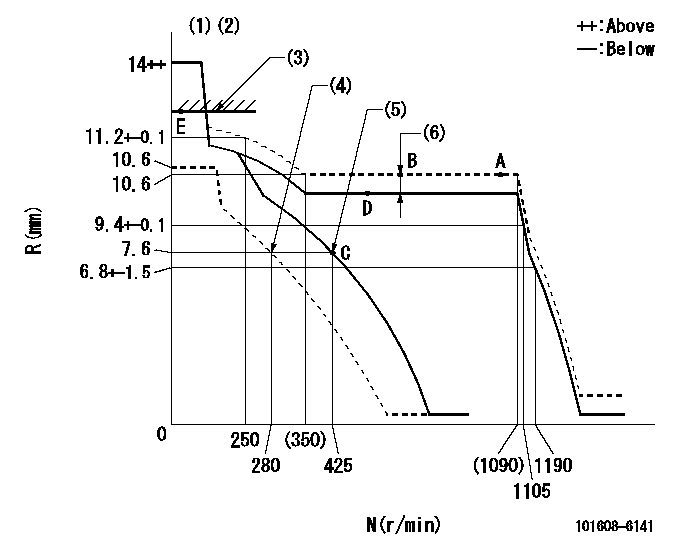

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

----------

K=10 BCL=0.7+-0.1mm

----------

----------

K=10 BCL=0.7+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(20deg)+-5deg b=(5deg)+-5deg

----------

----------

a=(20deg)+-5deg b=(5deg)+-5deg

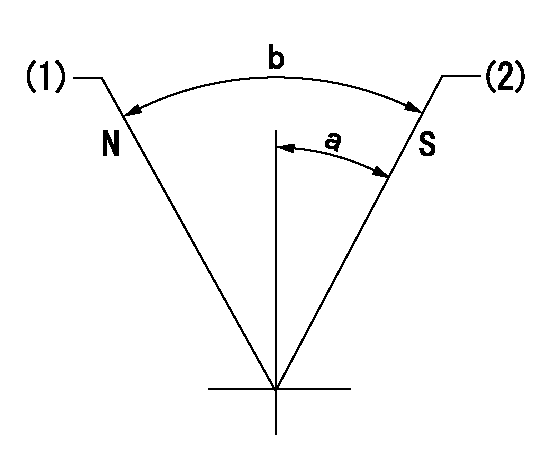

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(7deg)

----------

aa=14deg

----------

a=(7deg)

Information:

This is a 1.5-hour job for Group 2

1) An additional allowance of 4.0 hours can be claimed if the pump needs to be replaced after failing inspection.

2) Should the Dealer not have access to a Bore Scope an allowance of $250 per Dealer is allowed for the purchase of this tool.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

For NACD

Caterpillar Inc.

Attn: Supplier Recovery

Service Claims Room

8201 N. University

Peoria, IL 61615

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

SAFETY - PRODUCT IMPROVEMENT PROGRAM FOR THE INSPECTION AND POSSIBLE REPLACEMENT OF THE FUEL INJECTION PUMP ON CERTAIN TURBOCHARGED 414E, 416E, 420E, AND 430E BACKHOE LOADERS

MODELS INVOLVED - 414E, 416E, 420E, 430E

Dear Caterpillar Product Owner:

The Fuel Injection Pump needs to be inspected and possibly replaced on the products listed below. The existing Fuel Injection Pump can cause an unexpected increase in engine speed which may result in personal injury or death.

You will not be charged for the service performed.

Contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

Please refer the dealer to their Service Letter dated 08May2008 when scheduling this service.

We regret the inconvenience this may cause you, but urge you to have this service performed for your added safety and satisfaction.

Caterpillar Inc.

Identification #(s)

Attached to 08May2008 Service Letter

Rework Procedure

Tools required for the inspection of the fuel injection pump are:

17 mm hexagonal socket 3/8" drive.

3/8" drive ratchet wrench with 300 mm extension

Bore Scope with flexible end and ninety degree viewing lens. The Bore Scope has to be capable of being inserted in a 10 mm diameter hole. A 6 mm Bore Scope is recommended for optimium viewing.

1) Before proceeding, first check the serial number shown on the pump identification plate. Image 1.1.1

Image1.1.1

If the machine is identified in the Affected Product and the fuel pump serial number ends with the letter "B" as indicated in image 1.1.1 then the fuel pump should be further inspected.

2) Remove engine compartment door by removing the three bolts holding the door in place using a 13 mm ratchet and socket. Pull the rear of the door away from the machine and then pull the door towards the rear of the machine to remove it from the radiator guard. Image 1.2.1

Image1.2.1

3) Record pump and engine serial number.

Only carry out the following procedure if the pump type number is identified with the "B". (The pumps without the "B" are not affected by this problem).

4) Ensure the area around the fuel return connection is clean. The connection is on the top of the fuel pump toward the front of the engine. Image 1.3.1

Image1.3.1

5) Use a 17 mm X 3/8" drive hexagonal socket, extension 3/8" x 3/8" x 300 mm length and ratchet wrench 3/8" drive to release and remove the return connection fitting.

Note: Be careful not to damage the fitting and o-rings (image 1.4.1), and ensure nothing is

Have questions with 101608-6141?

Group cross 101608-6141 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

101608-6141

INJECTION-PUMP ASSEMBLY