Information injection-pump assembly

BOSCH

9 400 615 831

9400615831

ZEXEL

101608-1950

1016081950

MITSUBISHI

ME170447

me170447

Rating:

Include in #2:

104746-5790

as _

Cross reference number

BOSCH

9 400 615 831

9400615831

ZEXEL

101608-1950

1016081950

MITSUBISHI

ME170447

me170447

Zexel num

Bosch num

Firm num

Name

101608-1950

9 400 615 831

ME170447 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D17-2 K

6D17-2 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

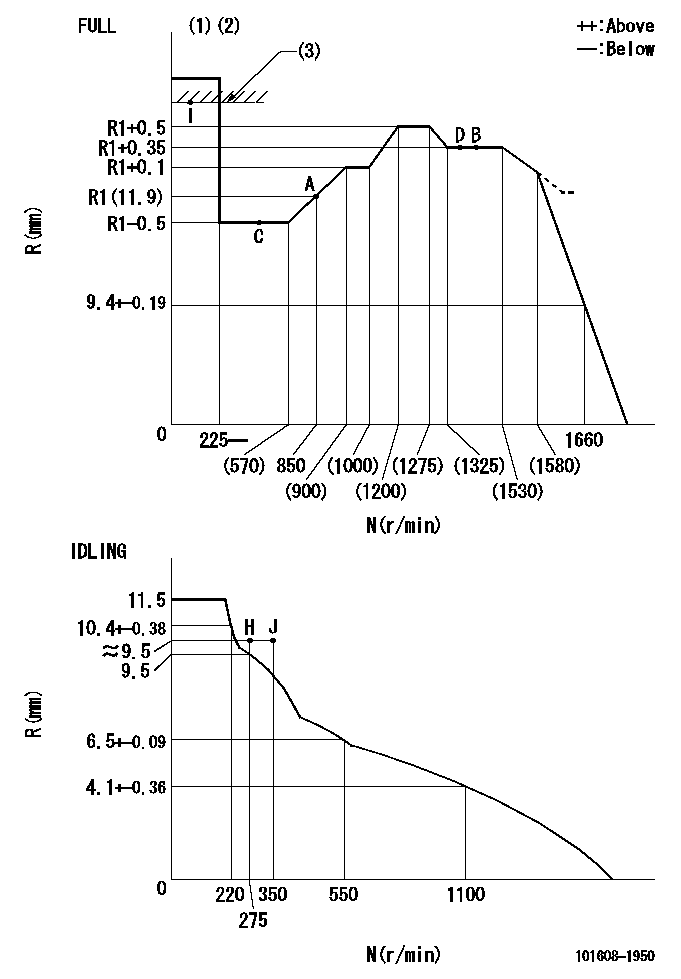

Injection quantity adjustment

Adjusting point

-

Rack position

11.9

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

81.5

79.1

83.9

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

600

600

600

Each cylinder's injection qty

mm3/st.

10.8

9.2

12.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.9)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

81.5

80.5

82.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.35

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

88

84

92

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

59.5

55.5

63.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

85

105

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1150--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1450

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=L01

----------

----------

T1=L01

----------

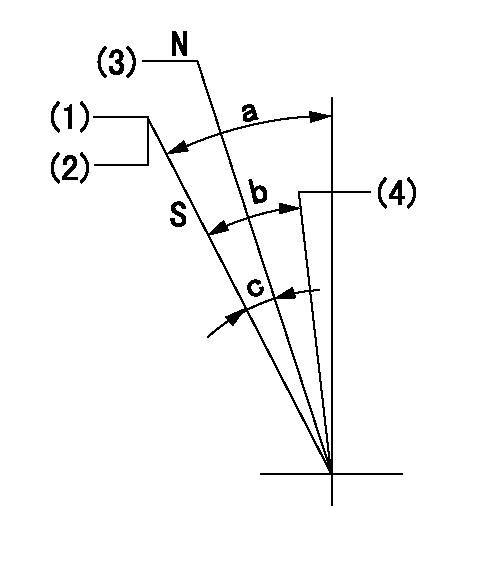

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=42deg+-3deg

----------

----------

a=18.5deg+-5deg b=42deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

(3)Rack position = approximately ee (speed lever full, speed = ff).

(4)Free (at delivery)

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm ff=0r/min

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm ff=0r/min

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

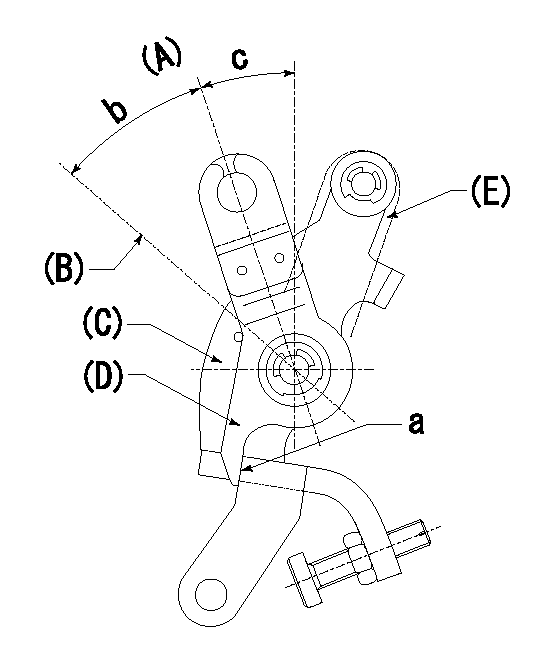

0000001501 LEVER

(A) Idle

(B) Full speed

(C) Base lever

(D) Accelerator lever

(E) Accelerator lever delivery position

1. Measure speed lever angle

(1)Measure the angle when the accelerator lever (D) contacted the base lever (C) at a.

----------

----------

b=42deg+-3deg c=18.5deg+-5deg

----------

----------

b=42deg+-3deg c=18.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=7deg

----------

a=(4deg)

----------

aa=7deg

----------

a=(4deg)

Information:

Starter Motor - Model - CA45

General Description

Designed for flange mounting, the C.A.45 starter motor has a uniform cylindrical shape with no surface protrusion. This is because the solenoid and main switch assemblies are housed within the drive end-shield, around (i.e., co-axially with) the armature shaft.The essential feature of the co-axial starter is that, the pinion alone moves axially to engage the engine flywheel. There is no longitudinal movement of the whole armature assembly, as in the axial types.Smooth engagement of the pinion with the engine flywheel is constantly ensured by using two-stage operation of the solenoid and switch mechanisms. Thus the risk of damage to both pinion and flywheel, through faulty meshing, is practically eliminated.In construction, the starter consists of three main sections, into which it can be easily dismantled.1. The solenoid switch-gear and pinion assembly housed in the drive end-shield.2. The armature, shaft and commutator assembly.3. The yoke, pole-piece and field-coil assembly.Ready access is possible therefore, to those parts most likely to require adjustment, such as the switchgear and commutator assemblies.The starter is designed for working off a 12 volt supply, with 17 amps solenoid current.Testing on the Vehicle

Ensure that the battery is in a charged condition.Switch on the lamps and operate the starter button. If the starter fails to function, but the lights maintain full brilliance, check the switch and battery connections to the starter and all external leads. Sluggish action of the starter can be caused by a poor or faulty connection.Difficulty in smooth engagement between starter and engine flywheel is probably due to dirt on the starter-shaft helices preventing free pinion movement. The shaft should be thoroughly cleaned with kerosene followed by the application of a small quantity of Caltex Thuben 90 or SAE 90 oil.Operating the Starter

When starting the engine the following points should be rigidly observed

1. Press the starter button firmly and release it immediately the engine fires.2. If the engine does not fire at once, let it come to rest before pressing the switch again.3. Do not run the battery down by keeping the starter switch pressed when the engine refuses to start. Ascertain the cause.4. On some engines it is often helpful to depress the clutch when starting.5. Do not operate the starter when the engine is running as serious damage may occur to both starter and flywheel.Maintenance

Lubrication

The large oil reservoir in the drive end shield need only be replenished during overhaul periods, when a supply of Shelltella T27 or BP Energol SHF 100 oil should be added through the oil plug.An oil impregnated sintered bronze bush is fitted at the commutator end, and needs no further attention.Brush Gear and Commutator

Inspect the brushes at intervals of approximately 500 hours. See that they are free in their guides and that the leads are quite free for movement, by easing back the brush springs and pulling gently on the flexible connections. If a brush is inclined to stick, remove it from its holder and clean the sides with a petrol moistened cloth.Be

General Description

Designed for flange mounting, the C.A.45 starter motor has a uniform cylindrical shape with no surface protrusion. This is because the solenoid and main switch assemblies are housed within the drive end-shield, around (i.e., co-axially with) the armature shaft.The essential feature of the co-axial starter is that, the pinion alone moves axially to engage the engine flywheel. There is no longitudinal movement of the whole armature assembly, as in the axial types.Smooth engagement of the pinion with the engine flywheel is constantly ensured by using two-stage operation of the solenoid and switch mechanisms. Thus the risk of damage to both pinion and flywheel, through faulty meshing, is practically eliminated.In construction, the starter consists of three main sections, into which it can be easily dismantled.1. The solenoid switch-gear and pinion assembly housed in the drive end-shield.2. The armature, shaft and commutator assembly.3. The yoke, pole-piece and field-coil assembly.Ready access is possible therefore, to those parts most likely to require adjustment, such as the switchgear and commutator assemblies.The starter is designed for working off a 12 volt supply, with 17 amps solenoid current.Testing on the Vehicle

Ensure that the battery is in a charged condition.Switch on the lamps and operate the starter button. If the starter fails to function, but the lights maintain full brilliance, check the switch and battery connections to the starter and all external leads. Sluggish action of the starter can be caused by a poor or faulty connection.Difficulty in smooth engagement between starter and engine flywheel is probably due to dirt on the starter-shaft helices preventing free pinion movement. The shaft should be thoroughly cleaned with kerosene followed by the application of a small quantity of Caltex Thuben 90 or SAE 90 oil.Operating the Starter

When starting the engine the following points should be rigidly observed

1. Press the starter button firmly and release it immediately the engine fires.2. If the engine does not fire at once, let it come to rest before pressing the switch again.3. Do not run the battery down by keeping the starter switch pressed when the engine refuses to start. Ascertain the cause.4. On some engines it is often helpful to depress the clutch when starting.5. Do not operate the starter when the engine is running as serious damage may occur to both starter and flywheel.Maintenance

Lubrication

The large oil reservoir in the drive end shield need only be replenished during overhaul periods, when a supply of Shelltella T27 or BP Energol SHF 100 oil should be added through the oil plug.An oil impregnated sintered bronze bush is fitted at the commutator end, and needs no further attention.Brush Gear and Commutator

Inspect the brushes at intervals of approximately 500 hours. See that they are free in their guides and that the leads are quite free for movement, by easing back the brush springs and pulling gently on the flexible connections. If a brush is inclined to stick, remove it from its holder and clean the sides with a petrol moistened cloth.Be

Have questions with 101608-1950?

Group cross 101608-1950 ZEXEL

Mitsubishi

101608-1950

9 400 615 831

ME170447

INJECTION-PUMP ASSEMBLY

6D17-2

6D17-2