Information injection-pump assembly

BOSCH

9 400 615 829

9400615829

ZEXEL

101608-1910

1016081910

MITSUBISHI

ME170441

me170441

Rating:

Include in #2:

104746-5710

as _

Cross reference number

BOSCH

9 400 615 829

9400615829

ZEXEL

101608-1910

1016081910

MITSUBISHI

ME170441

me170441

Zexel num

Bosch num

Firm num

Name

101608-1910

9 400 615 829

ME170441 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D17-2 K

6D17-2 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

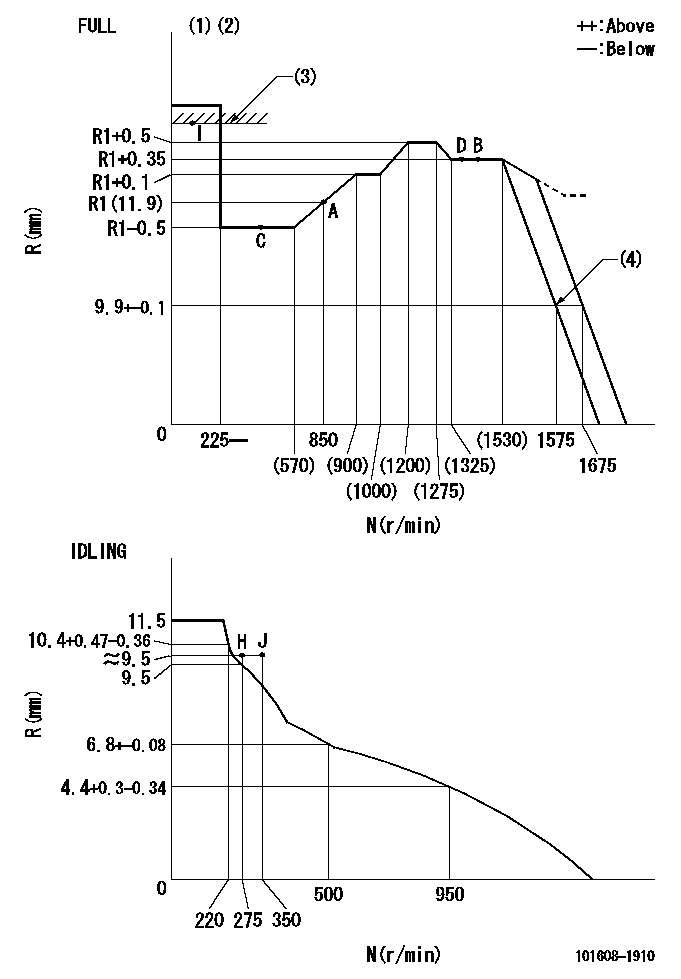

Injection quantity adjustment

Adjusting point

-

Rack position

11.9

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

81.5

79.1

83.9

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

600

600

600

Each cylinder's injection qty

mm3/st.

10.8

9.2

12.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.9)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

81.5

80.5

82.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.35

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

88

84

92

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

59.5

55.5

63.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

85

105

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1

0.5

1.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

1

0.5

1.5

Timer adjustment_05

Pump speed

r/min

1400

Advance angle

deg.

7

6.5

7.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set using the changeover lever.

----------

T1=L13

----------

----------

T1=L13

----------

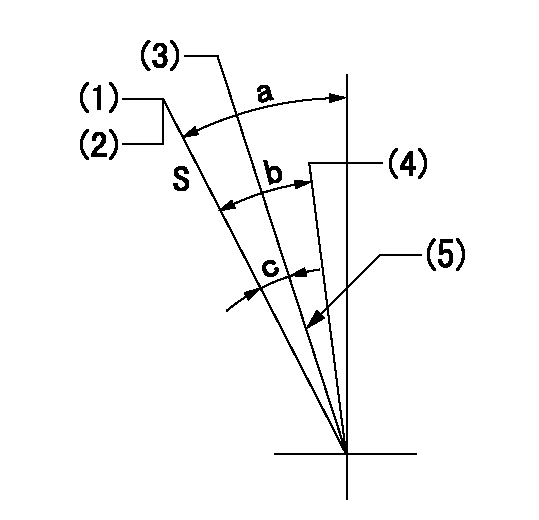

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=29mm

----------

a=10deg+-5deg b=(47.5deg)+-3deg

----------

aa=29mm

----------

a=10deg+-5deg b=(47.5deg)+-3deg

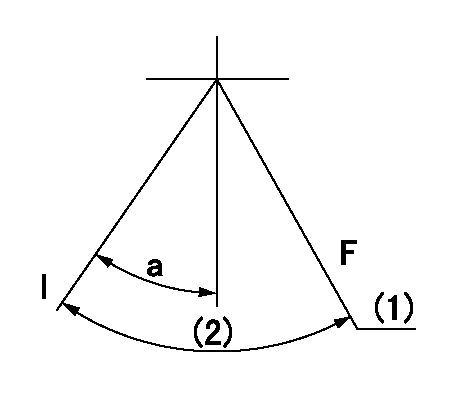

Stop lever angle

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

(3)Rack position = approximately ee (speed lever full, speed = ff).

(4)Free (at delivery)

(5)Normal use set at engine manufacturer.

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm ff=0r/min

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm ff=0r/min

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

0000001201

I:Idle

F:At operation, hold it in the full speed position.

(1)At rack position aa and pump speed bb, set the stopper bolt. (After setting it, apply red paint.)

(2)Actual measurement

----------

aa=9.9+-0.1mm bb=1575r/min

----------

a=15deg+-5deg

----------

aa=9.9+-0.1mm bb=1575r/min

----------

a=15deg+-5deg

0000001501 MICRO SWITCH

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

1. Microswitch adjustment (OPEN type)

Confirm with the lever angle at full.

(1)Speed N1

(2)Rack position Ra

2. Idle side microswitch adjustment (OPEN type)

Confirm with the lever angle at idle.

(1)Speed N2

(2)Rack position Rb

----------

N1=1675r/min Ra=9.9+-0.1mm N2=275r/min Rb=9.7+-0.1mm

----------

----------

N1=1675r/min Ra=9.9+-0.1mm N2=275r/min Rb=9.7+-0.1mm

----------

0000001601 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=3.57+-0.02V V2f=3+0.05V V2i=1+0.1V

----------

----------

V1=3.57+-0.02V V2f=3+0.05V V2i=1+0.1V

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=7deg

----------

a=(4deg)

----------

aa=7deg

----------

a=(4deg)

Information:

* Check that there is continuity between each stator lead.* If there is no continuity, the lead has broken.(2) Continuity between each lead wires and the core * Check that there is no continuity between lead wires and the core.* If there is continuity, the lead wire has short-circuited. Inspection: Brush* If the length of the brush has reached wear limit, replace the brush. Inspection: Rectifier* Check the function of diodes within rectifier properly. If any fault is found, replace the rectifier. If resistance is infinite in both cases, the diode is open.If resistance is close to 0 ohms in both cases, the diode is shorted.A, B, C: Lead connecting area of stator coilD, F: Heat sink areaE: Regulator connecting area* Inspection should be conducted twice, changed over the positive probe and the negative probe of the tester.* When inspecting using a tester, the current flowing through the rectifier is smaller than usual. Therefore, an incorrect resistance value may be indicated on the tester. Additionally, incorrect indications become larger as the range of the tester gets smaller. Set the tester to the largest possible scale. Assembly Procedure Assembly: Regulator and brush holder* To install the regulator and brush holder, follow the disassembly sequence in reverse. (See " Disassembly: Regulator and brush holder".) Assembly: Brush * Install brush on regulator and brush holder in the direction as illustrated.* After installation, solder the lead wire of brush on the regulator and brush holder. Thereafter, fit the cover as it was. Assembly: Stator* To install the stator, follow the disassembly sequence in reverse. (See " Disassembly: Stator".) Assembly: Rotor and rear bracket * If brush protrudes from regulator and brush holder, rotor cannot be installed onto the rear bracket. In this case, do the following:* Push brush into regulator and brush holder.* Insert pin into rear bracket from the rear to hold brush.* After assembly, remove pin gently.#950 Inspection Of Alternator

Performance Test* The general inspection is only a simplified check. use a test bench for accurate checking.* Connect the meters to the alternator as shown.

* To prevent possible injury, be sure to disconnect the negative terminal of

Performance Test* The general inspection is only a simplified check. use a test bench for accurate checking.* Connect the meters to the alternator as shown.

* To prevent possible injury, be sure to disconnect the negative terminal of

Have questions with 101608-1910?

Group cross 101608-1910 ZEXEL

Mitsubishi

101608-1910

9 400 615 829

ME170441

INJECTION-PUMP ASSEMBLY

6D17-2

6D17-2