Information injection-pump assembly

BOSCH

9 400 615 821

9400615821

ZEXEL

101608-1830

1016081830

MITSUBISHI

ME219043

me219043

Rating:

Include in #2:

104742-1700

as _

Cross reference number

BOSCH

9 400 615 821

9400615821

ZEXEL

101608-1830

1016081830

MITSUBISHI

ME219043

me219043

Zexel num

Bosch num

Firm num

Name

101608-1830

9 400 615 821

ME219043 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D34T K

6D34T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.1

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

77

76

78

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.6+-0.5

Pump speed

r/min

475

475

475

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

65

70

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

0

Advance angle

deg.

2

1.5

2.5

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2

1.5

2.5

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_03

Pump speed

r/min

700+-25

Advance angle

deg.

0

0

0

Remarks

Finish

Finish

Test data Ex:

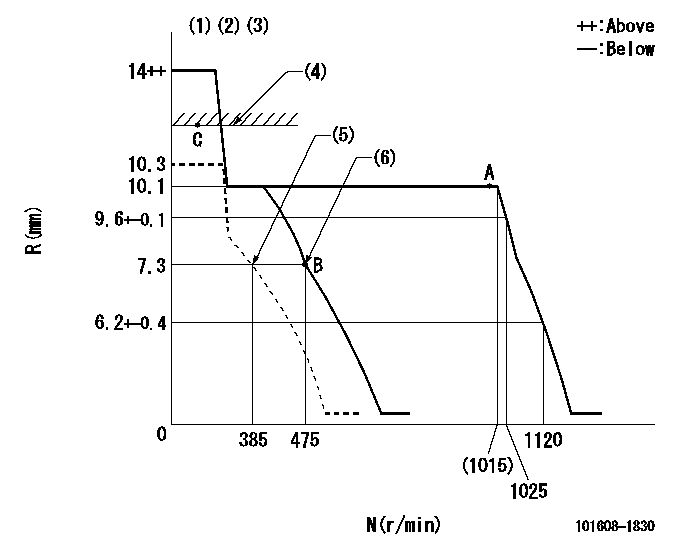

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Supplied with torque spring not set.

(4)RACK LIMIT

(5)Set idle sub-spring

(6)Main spring setting

----------

K=8

----------

----------

K=8

----------

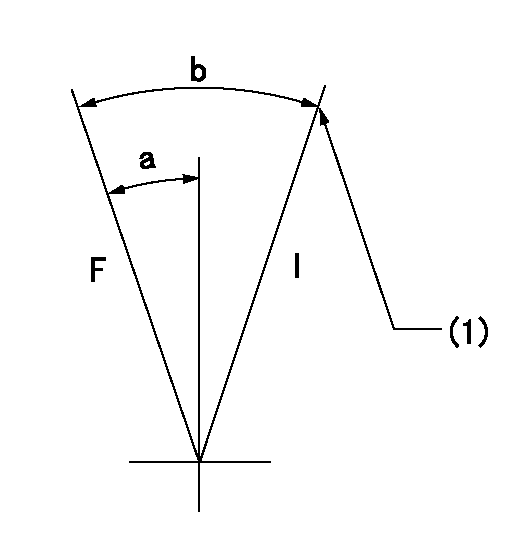

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=0deg+-5deg b=20deg+-5deg

----------

----------

a=0deg+-5deg b=20deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(130deg)

----------

aa=16deg

----------

a=(130deg)

Information:

To Reassemble

1. Fit oil feed connection to rocker shaft and secure with the locating screw, ensuring that the screw enters the locating hole in the shaft.2. Refit the support brackets, springs, and rocker levers in the correct order (Fig. E.4). The support brackets are interchangeable and when fitting them ensure that the securing stud/setscrew holes are to the right viewing the shaft from the front end, with each pair of rockers inclined away from each other at the valve end.3. Fit securing washer and circlip to each end of the shaft.Push Rods

Check the push rods for straightness. If any are bent, fit replacements.Valve Stem Oil Seals

Where oversize valves are fitted, always ensure that correct size valve seals or 'O' rings are used.

E3 1. Collets2. Valve Spring Cap3. Oil Deflector4. Inner Valve Spring5. Outer Valve Spring6. Valve Spring Seat7. Exhaust Valve8. Inlet ValveAll hydraulically governed engines and certain mechanically governed engines have rubber oil deflectors fitted to inlet valve stems only (see Fig. E.3). When fitting these oil deflectors, the open end should be towards the cylinder head.With the majority of mechanically governed engines, oil seals are fitted to both inlet and exhaust valves. Earlier engines had a shallow rubber oil deflector fitted to the valve stems and positioned above the conical valve spring seating collar, the open end of the deflector being fitted towards the cylinder head. Later engines have a thin valve spring seating washer and a rubber oil seal which fits over the integral valve guide protrusion. In some cases, this latter seal has a nylon insert. The later sealing arrangement, due to a change in the diameter of the valve guide protrusion, is not interchangeable with the earlier sealing arrangement.On some engines, the seals are manufactured from Viton or silicon rubber material and they have a garter spring fitted around their outer circumference.In manufacturing, some engines have a red coloured material for inlet valve seals and black for exhaust valve seals. The red seal may only be fitted over the inlet valve. It is unsuitable for exhaust valves but the black seal may be fitted to either exhaust or inlet.The 4.2482 engine has a valve stem oil seal on both inlet and exhaust valves. The seals have garter springs round the seal neck for improved oil control.To Re-Assemble the Cylinder Head

1. Lightly oil valve stems.2. Fit valve to its correct guide or bore.3. Fit valve stem oil seals.4. Locate spring seat washers, valve springs and spring caps in position.5. Compress each valve spring and fit the valve collets.

E11, Valve Cap Sealing Arrangement As from Engine No. LD-----U778518H, 'O' ring seals have been fitted in the valve spring caps under the collets. The valve spring caps have been changed which have a deeper body so that the seal can be fitted as shown in Fig. E.11. The new caps are fitted to both valves, but the seals are fitted to exhaust valves only. T4.236 engines have two 'O' rings fitted in each valve spring cap.Cylinder Head

1. Fit oil feed connection to rocker shaft and secure with the locating screw, ensuring that the screw enters the locating hole in the shaft.2. Refit the support brackets, springs, and rocker levers in the correct order (Fig. E.4). The support brackets are interchangeable and when fitting them ensure that the securing stud/setscrew holes are to the right viewing the shaft from the front end, with each pair of rockers inclined away from each other at the valve end.3. Fit securing washer and circlip to each end of the shaft.Push Rods

Check the push rods for straightness. If any are bent, fit replacements.Valve Stem Oil Seals

Where oversize valves are fitted, always ensure that correct size valve seals or 'O' rings are used.

E3 1. Collets2. Valve Spring Cap3. Oil Deflector4. Inner Valve Spring5. Outer Valve Spring6. Valve Spring Seat7. Exhaust Valve8. Inlet ValveAll hydraulically governed engines and certain mechanically governed engines have rubber oil deflectors fitted to inlet valve stems only (see Fig. E.3). When fitting these oil deflectors, the open end should be towards the cylinder head.With the majority of mechanically governed engines, oil seals are fitted to both inlet and exhaust valves. Earlier engines had a shallow rubber oil deflector fitted to the valve stems and positioned above the conical valve spring seating collar, the open end of the deflector being fitted towards the cylinder head. Later engines have a thin valve spring seating washer and a rubber oil seal which fits over the integral valve guide protrusion. In some cases, this latter seal has a nylon insert. The later sealing arrangement, due to a change in the diameter of the valve guide protrusion, is not interchangeable with the earlier sealing arrangement.On some engines, the seals are manufactured from Viton or silicon rubber material and they have a garter spring fitted around their outer circumference.In manufacturing, some engines have a red coloured material for inlet valve seals and black for exhaust valve seals. The red seal may only be fitted over the inlet valve. It is unsuitable for exhaust valves but the black seal may be fitted to either exhaust or inlet.The 4.2482 engine has a valve stem oil seal on both inlet and exhaust valves. The seals have garter springs round the seal neck for improved oil control.To Re-Assemble the Cylinder Head

1. Lightly oil valve stems.2. Fit valve to its correct guide or bore.3. Fit valve stem oil seals.4. Locate spring seat washers, valve springs and spring caps in position.5. Compress each valve spring and fit the valve collets.

E11, Valve Cap Sealing Arrangement As from Engine No. LD-----U778518H, 'O' ring seals have been fitted in the valve spring caps under the collets. The valve spring caps have been changed which have a deeper body so that the seal can be fitted as shown in Fig. E.11. The new caps are fitted to both valves, but the seals are fitted to exhaust valves only. T4.236 engines have two 'O' rings fitted in each valve spring cap.Cylinder Head

Have questions with 101608-1830?

Group cross 101608-1830 ZEXEL

Mitsubishi

Mitsubishi

101608-1830

9 400 615 821

ME219043

INJECTION-PUMP ASSEMBLY

6D34T

6D34T