Information injection-pump assembly

BOSCH

9 400 619 938

9400619938

ZEXEL

101608-1802

1016081802

MITSUBISHI

ME078437

me078437

Rating:

Service parts 101608-1802 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME078067

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Include in #1:

101608-1802

as INJECTION-PUMP ASSEMBLY

Include in #2:

104748-1704

as _

Cross reference number

BOSCH

9 400 619 938

9400619938

ZEXEL

101608-1802

1016081802

MITSUBISHI

ME078437

me078437

Zexel num

Bosch num

Firm num

Name

9 400 619 938

ME078437 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D16T * K 14BF INJECTION PUMP ASSY PE6AD PE

6D16T * K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

106

105

107

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

44

44

Boost pressure

mmHg

330

330

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

R1-0.9

Boost pressure

kPa

20

17.3

22.7

Boost pressure

mmHg

150

130

170

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

R1(10.6)

Boost pressure

kPa

30.7

24

37.4

Boost pressure

mmHg

230

180

280

Timer adjustment

Pump speed

r/min

1150--

Advance angle

deg.

0

0

0

Load

4/4

Remarks

Beginning of advance.

Beginning of advance.

Timer adjustment_02

Pump speed

r/min

450

Advance angle

deg.

2

1.5

2.5

Load

0/4

Remarks

Start

Start

Timer adjustment_03

Pump speed

r/min

(550)

Advance angle

deg.

0

0

0

Load

0/4

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

0.5

Load

4/4

Timer adjustment_05

Pump speed

r/min

1400

Advance angle

deg.

2.5

2

3

Load

4/4

Remarks

Finish

Finish

Test data Ex:

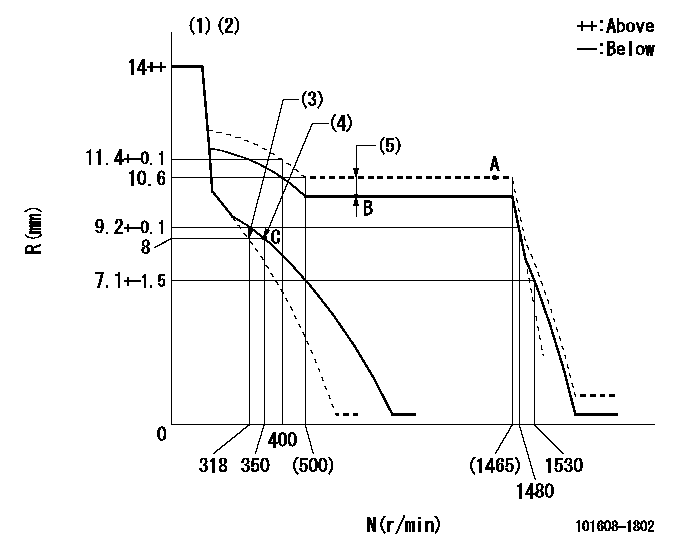

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Main spring setting

(4)Set idle sub-spring

(5)Boost compensator stroke: BCL

----------

K=13 BCL=0.9+-0.1mm

----------

----------

K=13 BCL=0.9+-0.1mm

----------

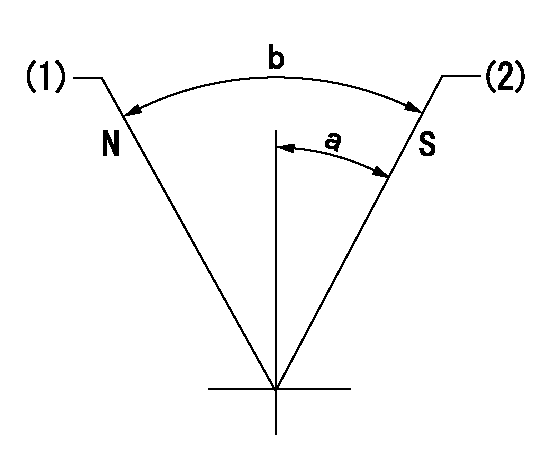

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(30deg)+-5deg b=(20deg)+-5deg

----------

----------

a=(30deg)+-5deg b=(20deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=4-0.5mm

----------

a=28deg+-5deg b=(48deg)

----------

aa=0r/min bb=4-0.5mm

----------

a=28deg+-5deg b=(48deg)

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(1deg)

----------

aa=10deg

----------

a=(1deg)

Information:

9-1345. Assemble screw to secure end plate of crankcase breather to the oil sump.Fig. 9-1346. Turn the engine over so that the cylinders are in the upward vertical position.

9-1357. Secure front vertical plate to cylinder. Secure fuel pipe for flame-type heater plug by clip.Fig. 9-135

9-1368. Position air cowling base, screw in central bolt and fit two washers. (Example: F5L)Fig. 9-136

9-1379. Install the oil cooler fitted with a a new rubber O-ring to seal against the lower part of the air cowling. Tighten the pipe unions.Fig. 9-137

9-13810. Fit bolts with washers for oil cooler.Fig. 9-138

9-13911. Secure exhaust air baffle.Fig. 9-139

9-14012. Fit rear vertical plate.Fig. 9-140

9-14113. Fit cooling blower to front-end cover.Fig. 9-141

9-14214. Position the upper cover plate on the cylinder heads.Fig. 9-14215. Connect fuel delivery lines, fitting new rubber mounting strip and new rubber sleeves.

9-14316. Connect the leak-off lines between the injectors and from one of the injectors to the injection pump. Assemble the long hollow screw in cylinder 1 and plug it to prevent the ingress of dirt.Fig. 9-143

9-14417. If the engine has a flame-type heater system, mount the solenoid valve on the front vertical plate.Fig. 9-14418. Install bracket mounting new fuel and lubricating oil filters and connect the fuel lines, fitting new gaskets.

9-14518.1. See Fig. 9-145 for F3L.

9-14618.2. See Fig. 9-146 for F4/6L.

9-14719. Install temperature sensors/contactors in cylinder heads. Starting Fig. 9-147 the following notes are applicable.

9-148 Sensor and contactor differ by their length. Fig. 9-148 shows sensor at left and contactor at right. Important:The direct-injection (D) and two-stage combustion (W) engines have contact makers (switches) of different temperature limits:D = 150° CW = 170° C

9-149 Cylinder numbering.Fig. 9-149The temperature sensor is secured to pickup point 1. A second sensor or a contactor is secured to point 2.

9-15020. Hook in the air cowling at the top and close at the bottom.Fig. 9-150

9-15121. Fit a new gasket in the oil filler cap. Replace the rubber gasket by a cork gasket.Fig. 9-15122. Close the oil filler; insert oil dipstick.

9-15223. Where an extra-long oil filler neck and dipstick guide have been provided, install filler neck with new O-ring in front-end cover and secure to cooling blower. Install dipstick guide.Fig. 9-152

9-15324. If the engine is fitted with an air compressor the oil return hole in the front cover plate must be left open. If the engine is not fitted with an air compressor a plug coated with jointing compound should be screwed into the oil return hole.Fig. 9-153 The next three operations apply only if the engine is fitted with an air compressor.

9-15425. Coat a new rubber O-seal with grease and stick it in position on the bracket of the air compressor.Fig. 9-154

9-15526. Mount the air compressor with bracket on the front cover plate.Fig. 9-155

9-15627. Install the high-pressure oil line, fitted with new gaskets, running from the oil gallery to the air compressor and tighten the female screws.Fig. 9-156

9-15728. Install new gaskets for the induction and exhaust manifolds with the flat end upwards.Fig. 9-157 On engines of more recent design, fit