Information injection-pump assembly

ZEXEL

101608-1800

1016081800

Rating:

Service parts 101608-1800 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME078067

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Cross reference number

ZEXEL

101608-1800

1016081800

Zexel num

Bosch num

Firm num

Name

101608-1800

INJECTION-PUMP ASSEMBLY

6D16T 14BF PE6AD PE

6D16T 14BF PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

106

105

107

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

44

44

Boost pressure

mmHg

330

330

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8

6.5

9.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

R1-0.9

Boost pressure

kPa

20

17.3

22.7

Boost pressure

mmHg

150

130

170

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

R1(10.6)

Boost pressure

kPa

30.7

24

37.4

Boost pressure

mmHg

230

180

280

Timer adjustment

Pump speed

r/min

1150--

Advance angle

deg.

0

0

0

Load

4/4

Remarks

Beginning of advance.

Beginning of advance.

Timer adjustment_02

Pump speed

r/min

450

Advance angle

deg.

2

1.5

2.5

Load

0/4

Remarks

Start

Start

Timer adjustment_03

Pump speed

r/min

(550)

Advance angle

deg.

0

0

0

Load

0/4

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

0.5

Load

4/4

Timer adjustment_05

Pump speed

r/min

1400

Advance angle

deg.

2.5

2

3

Load

4/4

Remarks

Finish

Finish

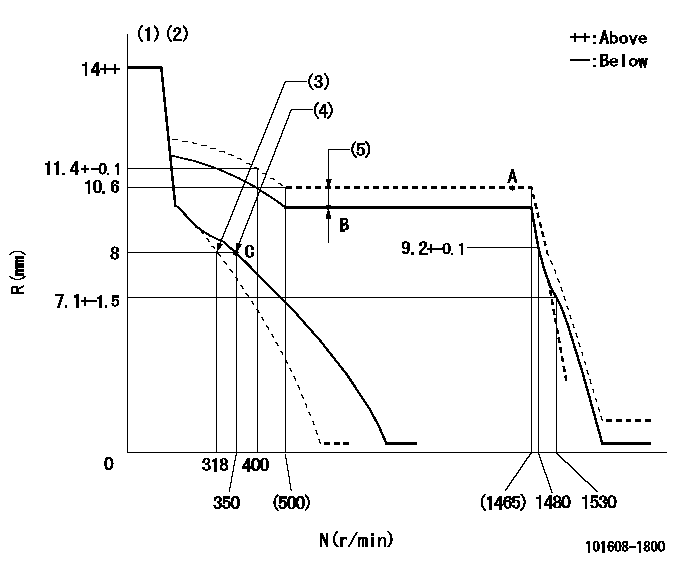

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Main spring setting

(4)Set idle sub-spring

(5)Boost compensator stroke: BCL

----------

K=13 BCL=0.9+-0.1mm

----------

----------

K=13 BCL=0.9+-0.1mm

----------

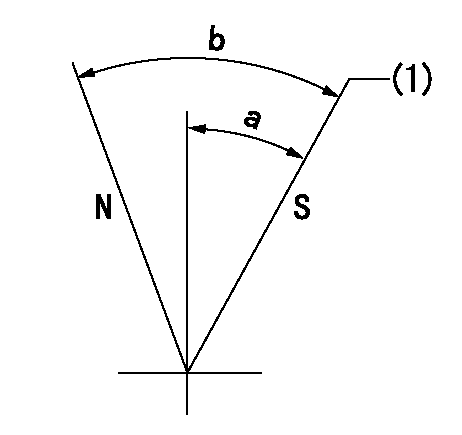

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(30deg)+-5deg b=(20deg)+-5deg

----------

----------

a=(30deg)+-5deg b=(20deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=(55deg)

----------

aa=0r/min bb=1-0.5mm

----------

a=35deg+-5deg b=(55deg)

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(1deg)

----------

aa=10deg

----------

a=(1deg)

Information:

6. Full-load Quantity for Starting a warmed-up Engine

When the engine is warmed-up, it is not necessary to operate the lever (9) for additional fuel.7. Stopping the Engine

For stopping the engine, the starting and stopping lever (9) must be pulled beyond the starting position until it rests firmly against the stop. When pulling the lever slowly, the engine will speed up again before stopping.8. Operating the Tractor

The hydraulic governor of the distributor-type pump functions in the same manner as a mechanical governor (RSV governor) of an in-line pump. It is, however, more sensitive to response than the mechanical governor.Pump Illustrations

Fuel Circuit Of Distributor - Type Pump

Checking The Fuel-Injection Pump Drive And Replacing Components (as from 3 cylinder engine)

1. Check the gearwheel and hub or injection timer. If necessary, dismantle the gearwheel from the hub or from the injection timer.2. Renew the defective component.

7-492.1 Assemble the gearwheel and hub so that the punch mark registers with the groove in the hub.Fig. 7-49, right2.2 Assemble the gearwhell to the injection timer so that the recess in the former registers with the groove in the hub.Fig. 7-49, left Important:As from 1975, the hub was modified in the case of rigid drive.

7-502.3 In the case of in-line injection pump, mount gearwheel onto steel hub.Fig. 7-50, right2.4 In the case of distributor injection pump, mount gearwheel reversed onto the hub.Fig. 7-50 left Observe markings and angular degrees.Dismantling And Installing Injectors

Dismantling:

1. Dismantle leak-off line to injector. Disconnect injection delivery line on injection.2. Dismantle stirrup and remove thrust piece.

7-513. Remove injector using extracting device No. 150800.Fig. 7-51, Attention:In addition, use threaded piece No. 110050 in case of lateral connection of injection delivery line.Fig. 7-51, leftUse extractor No. 110030 in case of top connection of injection delivery line.Fig. 7-51, right

7-52On FL 912 W remove injector by special wrench No. 110010 plus insert No. 110020.Fig. 7-52

7-534. Remove joint washer from injector or from cylinder head, as the case may be. (Extractor No. 120630)Fig. 7-53, leftIn case of FL 912 W, remove heat insulating plate (using, for example, bent wire).Fig. 7-53, rightInstalling:

7-541. Stick new joint washer with grease (graphited side facing towards injector).Fig. 7-54 On FL 912 install heat guard as shown.Fig. 7-53, right2. Install injector.

7-553. Install thrust piece and place stirrup in position.Fig. 7-55, left4. Place washer with convex side facing stirrup and screw on nut.(See Specification Data)5. On FL 912 W align injector to injection pipe.Fig. 7-55, right

7-566. Tighten injector by special wrench No. 110010 plus insert No. 110020.Fig. 7-567. Tighten injector and fit leak-oil line with new sealing rings.Removing And Refitting Injector On Engine Provided With Exhaust Air Heating

Preliminary work:

Injector is removed.1. Stick by means of grease sealing ring to injector and insert the latter in the cylinder head.

7-572. Slip rubber seal on injector and the vertical pin (see arrow) for fixture.Fig. 7-57

7-583. Apply leak oil pan (arrow). Slip spring and spacer sleeve on pin for fixture.Fig. 7-584. Apply clamping piece and fixture.5. Apply washer the curved side of which must show towards fixture; screw on

When the engine is warmed-up, it is not necessary to operate the lever (9) for additional fuel.7. Stopping the Engine

For stopping the engine, the starting and stopping lever (9) must be pulled beyond the starting position until it rests firmly against the stop. When pulling the lever slowly, the engine will speed up again before stopping.8. Operating the Tractor

The hydraulic governor of the distributor-type pump functions in the same manner as a mechanical governor (RSV governor) of an in-line pump. It is, however, more sensitive to response than the mechanical governor.Pump Illustrations

Fuel Circuit Of Distributor - Type Pump

Checking The Fuel-Injection Pump Drive And Replacing Components (as from 3 cylinder engine)

1. Check the gearwheel and hub or injection timer. If necessary, dismantle the gearwheel from the hub or from the injection timer.2. Renew the defective component.

7-492.1 Assemble the gearwheel and hub so that the punch mark registers with the groove in the hub.Fig. 7-49, right2.2 Assemble the gearwhell to the injection timer so that the recess in the former registers with the groove in the hub.Fig. 7-49, left Important:As from 1975, the hub was modified in the case of rigid drive.

7-502.3 In the case of in-line injection pump, mount gearwheel onto steel hub.Fig. 7-50, right2.4 In the case of distributor injection pump, mount gearwheel reversed onto the hub.Fig. 7-50 left Observe markings and angular degrees.Dismantling And Installing Injectors

Dismantling:

1. Dismantle leak-off line to injector. Disconnect injection delivery line on injection.2. Dismantle stirrup and remove thrust piece.

7-513. Remove injector using extracting device No. 150800.Fig. 7-51, Attention:In addition, use threaded piece No. 110050 in case of lateral connection of injection delivery line.Fig. 7-51, leftUse extractor No. 110030 in case of top connection of injection delivery line.Fig. 7-51, right

7-52On FL 912 W remove injector by special wrench No. 110010 plus insert No. 110020.Fig. 7-52

7-534. Remove joint washer from injector or from cylinder head, as the case may be. (Extractor No. 120630)Fig. 7-53, leftIn case of FL 912 W, remove heat insulating plate (using, for example, bent wire).Fig. 7-53, rightInstalling:

7-541. Stick new joint washer with grease (graphited side facing towards injector).Fig. 7-54 On FL 912 install heat guard as shown.Fig. 7-53, right2. Install injector.

7-553. Install thrust piece and place stirrup in position.Fig. 7-55, left4. Place washer with convex side facing stirrup and screw on nut.(See Specification Data)5. On FL 912 W align injector to injection pipe.Fig. 7-55, right

7-566. Tighten injector by special wrench No. 110010 plus insert No. 110020.Fig. 7-567. Tighten injector and fit leak-oil line with new sealing rings.Removing And Refitting Injector On Engine Provided With Exhaust Air Heating

Preliminary work:

Injector is removed.1. Stick by means of grease sealing ring to injector and insert the latter in the cylinder head.

7-572. Slip rubber seal on injector and the vertical pin (see arrow) for fixture.Fig. 7-57

7-583. Apply leak oil pan (arrow). Slip spring and spacer sleeve on pin for fixture.Fig. 7-584. Apply clamping piece and fixture.5. Apply washer the curved side of which must show towards fixture; screw on

Have questions with 101608-1800?

Group cross 101608-1800 ZEXEL

101608-1800

INJECTION-PUMP ASSEMBLY

6D16T

6D16T