Information injection-pump assembly

BOSCH

9 400 615 818

9400615818

ZEXEL

101608-1770

1016081770

MITSUBISHI

ME219005

me219005

Rating:

Include in #1:

107692-1801

as _

Cross reference number

BOSCH

9 400 615 818

9400615818

ZEXEL

101608-1770

1016081770

MITSUBISHI

ME219005

me219005

Zexel num

Bosch num

Firm num

Name

101608-1770

9 400 615 818

ME219005 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D34T K

6D34T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.5

3.45

3.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.2

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

76

75

77

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7+-0.5

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

65

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

0

Advance angle

deg.

2

1.5

2.5

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2

1.5

2.5

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_03

Pump speed

r/min

850+-25

Advance angle

deg.

0

0

0

Remarks

Finish

Finish

Test data Ex:

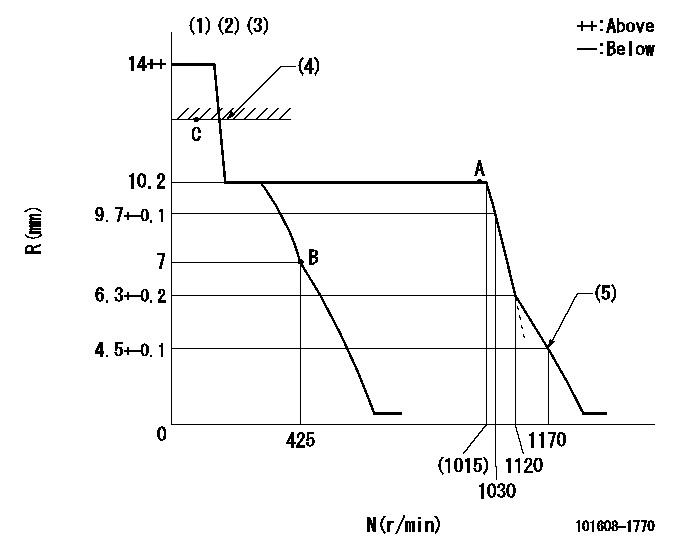

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Deliver with the torque spring and the torque control spring not operating.

(4)RACK LIMIT

(5)Set idle sub-spring

----------

K=13

----------

----------

K=13

----------

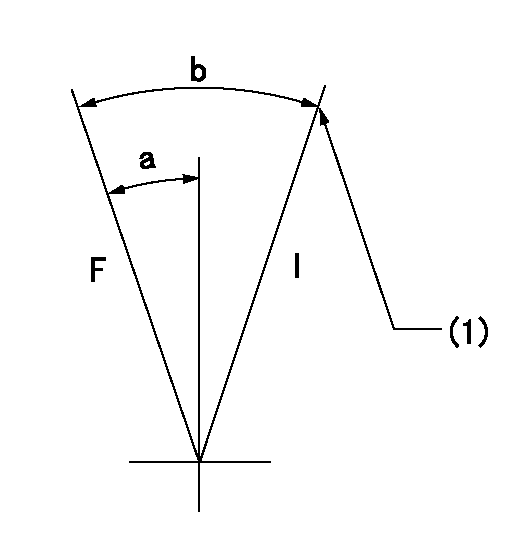

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=5deg+-5deg b=18deg+-5deg

----------

----------

a=5deg+-5deg b=18deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(130deg)

----------

aa=16deg

----------

a=(130deg)

Information:

Checking The Piston

1. If the cylinder is renewed, a new piston must be fitted. Normal and oversizes are given in the specifications.2. Inspect the piston for damage or visible wear, including the bosses.

3-613. Remove the compression rings and bevelled scraper ring. (Use piston-ring expander No. 130300)Fig. 3-61

3-624. Open and remove the expander spring for the bevelled scraper ring.Fig. 3-625. Clean the piston-ring grooves.

3-636. Measure axial piston ring clearance by using commercial tools.Fig. 3-63, leftMeasure first piston ring groove, if trapezoidal, by means of trapezoidal groove wear gauge No. 130360.Fig. 3-63, right

3-64 If, when measuring a piston with trapezoidal ring groove, a gap "S" (Fig. 3-64) is found to exist between the inserted gauge and the piston, this means that the axial piston ring clearance is within the tolerances stated in the Specification Data and the piston is fit for further use.

3-65But if the gauge contacts the side of the piston (see Fig. 3-65), i.e. without gap, the piston has to be renewed.

3-667. Insert all the piston rings singly in the cylinder and press down with the piston to a distance of 30 mm from the cylinder head contacting surface. Measure the gap clearance of the piston ring.Fig. 3-668. Compare the gap clearances of the piston rings with the values given in the specifications.9. Renew defective pistons together with gudgeon pin and rings. Renew also cylinders.

3-6710. When installing the piston rings start by fitting the expander spring for the bevelled scraper ring in the bottom groove.Fig. 3-67

3-6811. Assemble the piston rings with the aid of piston-ring expander No. 130300, in the following sequence:No. 3 (No. 4) Slotted, double-chamfered oil-control ring, chromium-plated.(No. 3) Tapered compression ring, ferrox finished; install with face marked "top" upwards.No. 2 Tapered compression ring, ferrox finished; install with face marked "top" upwards.No. 1 Top, double-trapezoidal compression ring, chromium-plated. "top" upwards.Fig. 3-68 Place the rings so that the gaps are evenly spaced around the piston.

3-6912. Check piston pin for wear using a bevelled steel straight edge or measuring angle, Fig. 3-69.

3-70 Secure the opposite end of the gudgeon pin in position. Place the piston on the small end of the connecting rod so that the exhaust air side of the piston (marked on the piston crown) is in the same direction as the open side of the connecting-rod bearing. Press in the gudgeon pin.Fig. 3-70Checking The Connecting Rod

Gauging and replacing piston pin bush

3-711. Set inside micrometer to starting dimension using a micrometer frame (see Technical Data).Fig. 3-71

3-722. Measure the piston pin bush at points one and two in the planes "a" and "b".Fig. 3-72 Attention:Compare recorded values with those specified in the Technical Data.

3-733. Pull out old piston pin bush with fixture No. 131310 and pull in new piston pin bush with the same device.Fig. 3-73

3-74 Note for installation:Pull in the new piston pin bush flush, making sure that the oil bores in bush and connecting rod coincide.Fig. 3-74Gauging And Replacing Big-End Bearings

3-75The big-end bearings are of finished type. They are made of two half

1. If the cylinder is renewed, a new piston must be fitted. Normal and oversizes are given in the specifications.2. Inspect the piston for damage or visible wear, including the bosses.

3-613. Remove the compression rings and bevelled scraper ring. (Use piston-ring expander No. 130300)Fig. 3-61

3-624. Open and remove the expander spring for the bevelled scraper ring.Fig. 3-625. Clean the piston-ring grooves.

3-636. Measure axial piston ring clearance by using commercial tools.Fig. 3-63, leftMeasure first piston ring groove, if trapezoidal, by means of trapezoidal groove wear gauge No. 130360.Fig. 3-63, right

3-64 If, when measuring a piston with trapezoidal ring groove, a gap "S" (Fig. 3-64) is found to exist between the inserted gauge and the piston, this means that the axial piston ring clearance is within the tolerances stated in the Specification Data and the piston is fit for further use.

3-65But if the gauge contacts the side of the piston (see Fig. 3-65), i.e. without gap, the piston has to be renewed.

3-667. Insert all the piston rings singly in the cylinder and press down with the piston to a distance of 30 mm from the cylinder head contacting surface. Measure the gap clearance of the piston ring.Fig. 3-668. Compare the gap clearances of the piston rings with the values given in the specifications.9. Renew defective pistons together with gudgeon pin and rings. Renew also cylinders.

3-6710. When installing the piston rings start by fitting the expander spring for the bevelled scraper ring in the bottom groove.Fig. 3-67

3-6811. Assemble the piston rings with the aid of piston-ring expander No. 130300, in the following sequence:No. 3 (No. 4) Slotted, double-chamfered oil-control ring, chromium-plated.(No. 3) Tapered compression ring, ferrox finished; install with face marked "top" upwards.No. 2 Tapered compression ring, ferrox finished; install with face marked "top" upwards.No. 1 Top, double-trapezoidal compression ring, chromium-plated. "top" upwards.Fig. 3-68 Place the rings so that the gaps are evenly spaced around the piston.

3-6912. Check piston pin for wear using a bevelled steel straight edge or measuring angle, Fig. 3-69.

3-70 Secure the opposite end of the gudgeon pin in position. Place the piston on the small end of the connecting rod so that the exhaust air side of the piston (marked on the piston crown) is in the same direction as the open side of the connecting-rod bearing. Press in the gudgeon pin.Fig. 3-70Checking The Connecting Rod

Gauging and replacing piston pin bush

3-711. Set inside micrometer to starting dimension using a micrometer frame (see Technical Data).Fig. 3-71

3-722. Measure the piston pin bush at points one and two in the planes "a" and "b".Fig. 3-72 Attention:Compare recorded values with those specified in the Technical Data.

3-733. Pull out old piston pin bush with fixture No. 131310 and pull in new piston pin bush with the same device.Fig. 3-73

3-74 Note for installation:Pull in the new piston pin bush flush, making sure that the oil bores in bush and connecting rod coincide.Fig. 3-74Gauging And Replacing Big-End Bearings

3-75The big-end bearings are of finished type. They are made of two half

Have questions with 101608-1770?

Group cross 101608-1770 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

101608-1770

9 400 615 818

ME219005

INJECTION-PUMP ASSEMBLY

6D34T

6D34T