Information injection-pump assembly

BOSCH

9 400 615 817

9400615817

ZEXEL

101608-1761

1016081761

MITSUBISHI

ME170302

me170302

Rating:

Include in #1:

107692-1800

as _

Cross reference number

BOSCH

9 400 615 817

9400615817

ZEXEL

101608-1761

1016081761

MITSUBISHI

ME170302

me170302

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8260

Bosch type code

9 430 610 133

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

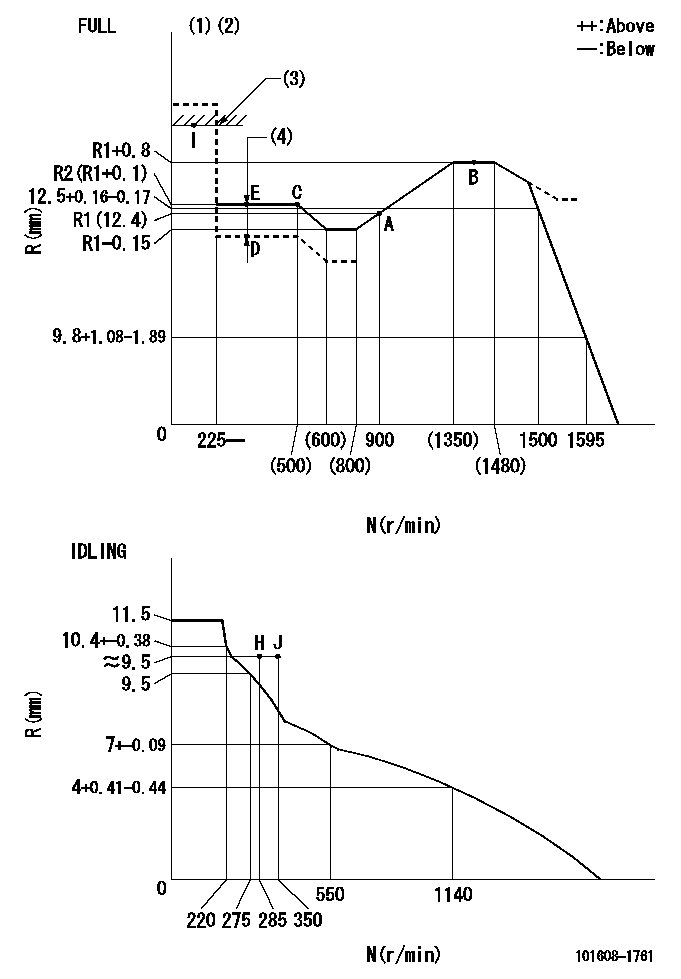

Injection quantity adjustment

Adjusting point

-

Rack position

12.4

Pump speed

r/min

900

900

900

Each cylinder's injection qty

mm3/st.

110.5

107.2

113.8

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

12.5

10.6

14.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.4)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

110.5

109.5

111.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

70.6

70.6

Boost pressure

mmHg

530

530

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.8

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

115.5

111.5

119.5

Fixing the lever

*

Boost pressure

kPa

70.6

70.6

Boost pressure

mmHg

530

530

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1+0.1)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

130.5

126.5

134.5

Fixing the lever

*

Boost pressure

kPa

70.6

70.6

Boost pressure

mmHg

530

530

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2-1.35

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

88

84

92

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

160

160

170

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

R2-1.35

Boost pressure

kPa

13.3

13.3

13.3

Boost pressure

mmHg

100

100

100

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

R2-0.55

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Boost compensator adjustment_03

Pump speed

r/min

400

400

400

Rack position

R2(R1+0.

1)

Boost pressure

kPa

57.3

57.3

57.3

Boost pressure

mmHg

430

430

430

Timer adjustment

Pump speed

r/min

(N1+50)-

-

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

0.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

3.5

3.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=N21 BCL=1.35+-0.1mm

----------

----------

T1=N21 BCL=1.35+-0.1mm

----------

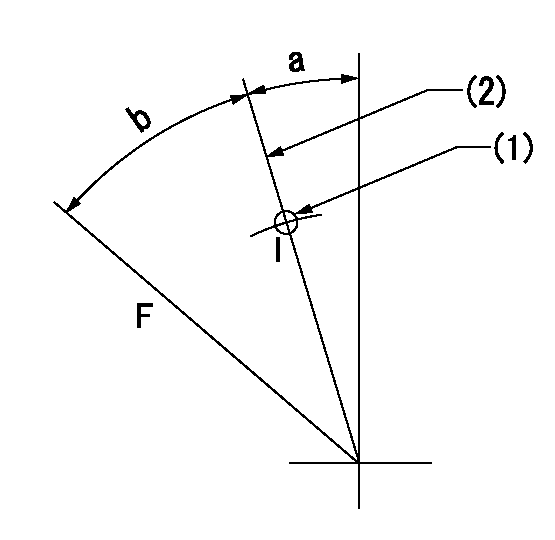

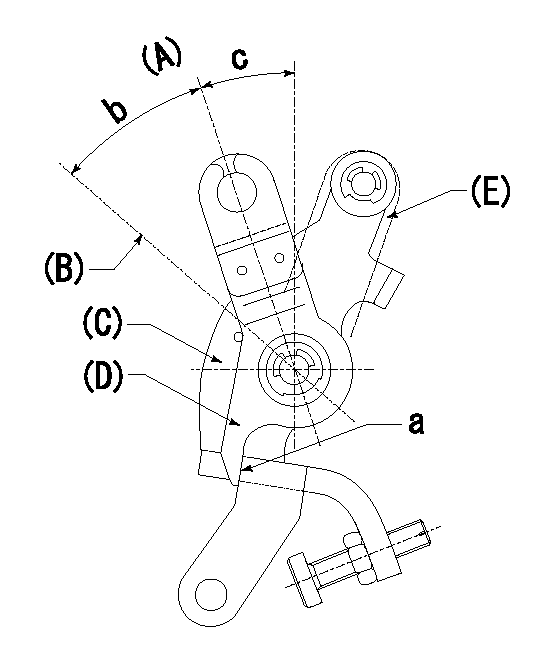

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=40mm

----------

a=19deg+-5deg b=41.5deg+-3deg

----------

aa=40mm

----------

a=19deg+-5deg b=41.5deg+-3deg

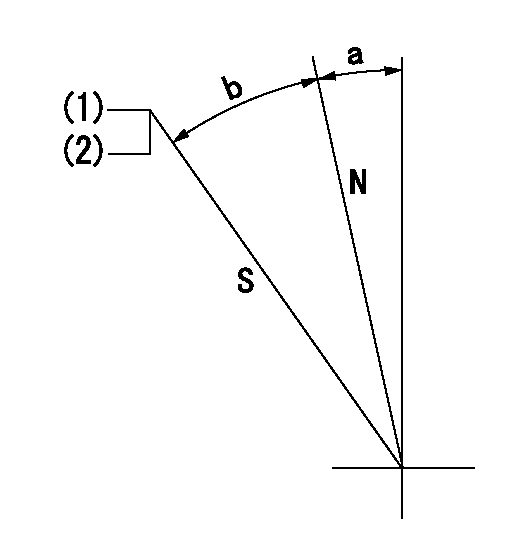

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)With the speed lever at Full, set the stopper bolt so that speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt at the speed lever's idle position, confirm that there is no injection at pump speed cc and rack position dd (non-injection rack position).

----------

aa=1400r/min bb=7-0.5mm cc=285r/min dd=(7.3)mm

----------

a=11.5deg+-5deg b=28deg+-5deg

----------

aa=1400r/min bb=7-0.5mm cc=285r/min dd=(7.3)mm

----------

a=11.5deg+-5deg b=28deg+-5deg

0000001501 LEVER

(A) Idle

(B) Full speed

(C) Base lever

(D) Accelerator lever

(E) Accelerator lever delivery position

1. Measure speed lever angle

(1)Measure the angle when the accelerator lever (D) contacted the base lever (C) at a.

----------

----------

b=41.5deg+-3deg c=19deg+-5deg

----------

----------

b=41.5deg+-3deg c=19deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

2-302. Dismantle the vee-belt idler or cover. Slacken the screw on the injection pump drive with special spanner No. 110310.Fig. 2-30

2-31

2-323. Slowly rotate the injection pump shaft in the direction of normal rotation until the pump starts to deliver fuel. (Use double spanner No. 110330 or a 19 mm socket spanner)Fig. 2-31 and 2-324. Check that fuel comes out from overflow pipe (when operating test unit or pump) only in droplets at intervals of 5-8 seconds.5. Retain the injection pump shaft in this position and tighten the screws on the injection pump drive, using special spanner No. 110310.6. Re-check the fuel-injection point and correct, if necessary. Turn off the high-pressure tester.

2-337. Assemble the vee-belt idler or cover with a new rubber O-ring. Dismantle the timing device. Connect the fuel lines, free from tension, and assemble the cover on the injection pump.Fig. 2-33Testing The Injection Nozzle (by testing outfit)

Injector is removed.

2-341. Connect injector to outfit.Fig. 2-34

2-352. With pressure gauge cut in, press outfit pump lever several times. Read opening pressure (Fig. 2-35) and inspect spray pattern. Compare readings with Specification Data. Important:At 25 - 30 bar below specified opening pressure, check that no fuel will dribble from nozzle.

2-363. Adjust nozzle opening pressure by shims below the spring (adding shims increases pressure and vice versa). Shims of the following thicknesses are available: 1.0; 1.05; 1.1; 1.15; etc. up to 1.95 mm.Fig. 2-36 Note for Refitment:By adding shims the pressure will be increased; by removing them the pressure will be decreased.

2-37For FL 912W, adjust release pressure by means of set-screw. By turning in screw, release pressure is increased; by turning it out, pressure is decreased.Fig. 2-37

2-384. Repeat test and recheck spray pattern. The jet(s) should be solid without surrounding mist. Fig. 2-38

2-39FL 912/W: one jet onlyFig. 2-395. Check that there is no after-dribble.6. If nozzle works unsatisfactorily, replace.Testing The Injection Pump (by special outfit)

The test is confined to making sure that the delivery valves and pump elements are free from leaks. The fuel feed pump intake is connected to the fuel tank or a receptacle containing filtered fuel. Proper fuel delivery is a prerequisite.

2-401. Disconnect injection line(s) on the fuel-injection pump. Evacuate the air from the fuel injection pump. Connect the tester to the pump element to be checked.Fig. 2-40

2-412. Open the second connection of the tester and evacuate the air. When the escaping fuel is free from bubbles, close the second connection.Fig. 2-41 The manual operation of the fuel-injection pump elements differs from one type of engine to another.F2L: Rotate the crankshaft until the air is evacuated or until the pressure has built up.

2-42As from 3 cylinder engine: Lower the tappet of the element to be checked by turning the crankshaft and then pump with a lever.Fig. 2-423. To check a pressure relief valve, generate a pressure of 150 bar. The indicator of the pressure gauge may not drop back more than 10 bar during a minute.

2-434. Generate a pressure peak of 350 bar. This must be clearly indicated by