Information injection-pump assembly

BOSCH

9 400 610 752

9400610752

ZEXEL

101608-1380

1016081380

Rating:

Service parts 101608-1380 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME078066

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 610 752

9400610752

ZEXEL

101608-1380

1016081380

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

82

81

83

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.6

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

100

96

104

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.6+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

11.5

10

13

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

1200--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

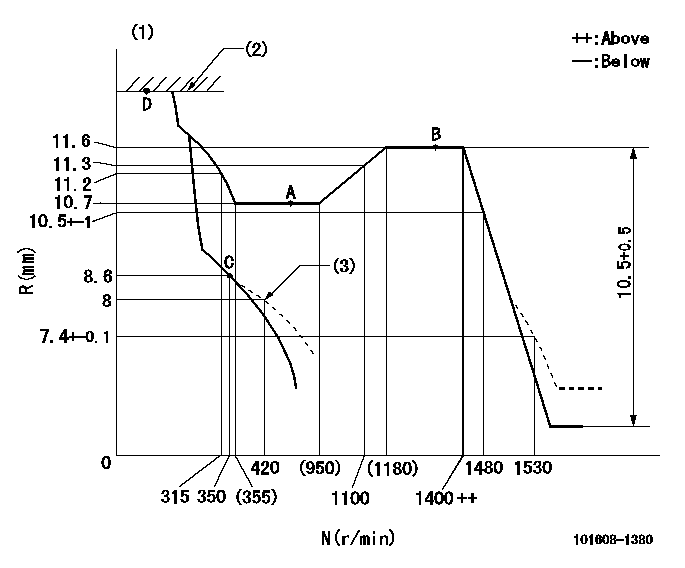

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Excess fuel setting for starting

(3)Damper spring setting

----------

----------

----------

----------

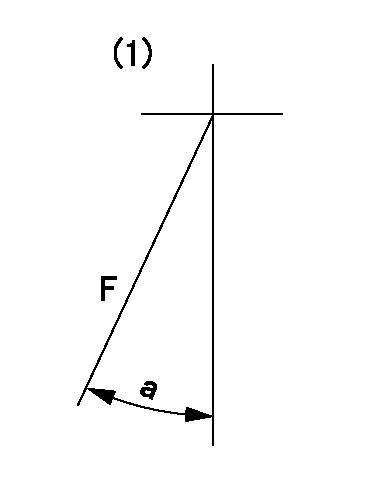

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(18deg)+-5deg b=(6deg)+-5deg

----------

----------

a=(18deg)+-5deg b=(6deg)+-5deg

0000000901

F:Full load

(1)Fix the lever at the full load position

----------

----------

a=16deg+-5deg

----------

----------

a=16deg+-5deg

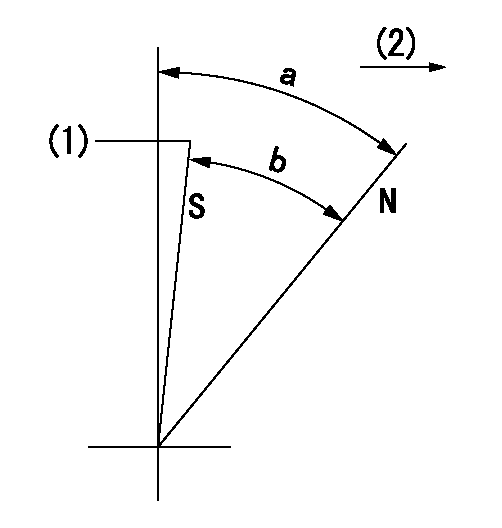

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set stopper bolt so that rack position = aa (after adjusting, apply red paint).

(2)Drive side

----------

aa=5.9-0.5mm

----------

a=57deg+-5deg b=52deg+7eg-5deg

----------

aa=5.9-0.5mm

----------

a=57deg+-5deg b=52deg+7eg-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(0deg)

----------

aa=12deg

----------

a=(0deg)

Information:

Table 1

Diagnostic Trouble Codes

J1939 Code and Description CDL Code and Description

4334–20

Aftertreatment #1 DEF #1 Pressure (absolute) : Data Drifted High 3090–20

Aftertreatment #1 DEF Pressure Sensor : Data Drifted High

4334-21

Aftertreatment #1 DEF #1 Pressure (absolute) : Data Drifted Low 3090-21

Aftertreatment #1 DEF Pressure Sensor : Data Drifted Low

3361-5

Aftertreatment #1 DEF Dosing Unit : Current Below Normal 3821-5

Aftertreatment #1 Diesel Exhaust Fluid Dosing Valve Actuator : Current Below Normal

3361-6

Aftertreatment #1 DEF Dosing Unit : Current Above Normal 3821-6

Aftertreatment #1 Diesel Exhaust Fluid Dosing Valve Actuator : Current Above Normal

3516-12

Aftertreatment #1 DEF Concentration : Failure 3100-12

Aftertreatment #1 DEF Tank Fluid Quality Sensor : Failure

Table 2

Event Codes

J1939 Code and Description CDL Code and Description

5392-31

Aftertreatment Diesel Exhaust Fluid Dosing Unit Loss of Prime E1370 (2)

Aftertreatment #1 DEF Dosing Unit Loss of Prime

4334-18

Aftertreatment #1 DEF #1 Pressure (absolute) : Low - moderate severity (2) E931 (2)

Low Aftertreatment #1 DEF Pressure

4334-16

Aftertreatment #1 DEF #1 Pressure (absolute) : High - moderate severity (2) E930 (2)

High Aftertreatment #1 DEF Pressure

3516-16

Aftertreatment #1 DEF Concentration : High - moderate severity (2) E1365 (2)

High Aftertreatment #1 DEF Concentration

3516-18

Aftertreatment #1 DEF Concentration : Low - moderate severity (2) E1364 (2)

Low Aftertreatment #1 DEF Concentration

5246-15

Aftertreatment SCR Operator Inducement Severity : High - least severe (1) E1389 (1)

Aftertreatment #1 SCR Operator Inducement

5246-16

Aftertreatment SCR Operator Inducement Severity : High - moderate severity (2) E1389 (2)

Aftertreatment #1 SCR Operator Inducement

5246-0

Aftertreatment SCR Operator Inducement Severity : High - most severe (3) E1389 (3)

Aftertreatment #1 SCR Operator Inducement Ensure that DEF fluid conforms to specification ISO 22241 requirements and fluid handling, filling, and storage procedures are strictly followed.All transfer equipment and storage containers should be used exclusively for DEF and should not be reused for other fluids. For example coolants, fuels, oils, and windshield washer fluid.If contamination of the DEF system is suspected, refer to Troubleshooting, DEF Concentration is Incorrect. Ensure that the correct troubleshooting steps are followed. To test for contamination of the DEF tank, refer to Systems Operation Testing and Adjusting, Diesel Exhaust Fluid Quality - Test.If the DEF is contaminated, Caterpillar recommends that the DEF tank is flushed. Refer to Systems Operation Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush for the correct procedure.