Information injection-pump assembly

BOSCH

9 400 613 506

9400613506

ZEXEL

101608-1070

1016081070

MITSUBISHI

ME075716

me075716

Rating:

Service parts 101608-1070 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/21.6{220}

14.

NOZZLE

Include in #1:

101608-1070

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-5540

as _

Cross reference number

BOSCH

9 400 613 506

9400613506

ZEXEL

101608-1070

1016081070

MITSUBISHI

ME075716

me075716

Zexel num

Bosch num

Firm num

Name

101608-1070

9 400 613 506

ME075716 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D17 K 14BF INJECTION PUMP ASSY PE6AD PE

6D17 K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

85.1

82.5

87.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

800

800

800

Each cylinder's injection qty

mm3/st.

10.8

9.2

12.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

85.1

84.1

86.1

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.85

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

99.9

95.9

103.9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

91

81

101

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1150--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1450

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

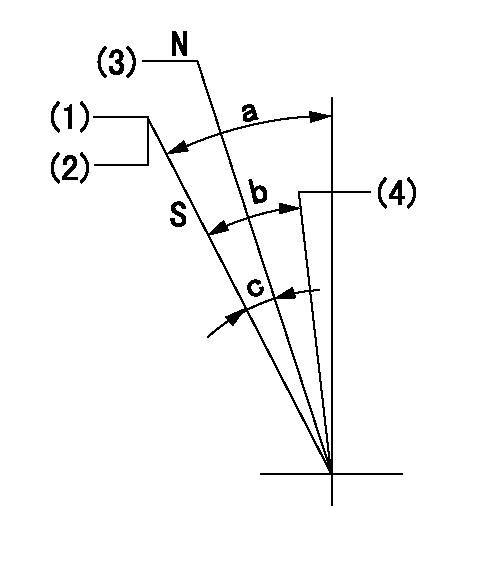

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=G43

----------

----------

T1=G43

----------

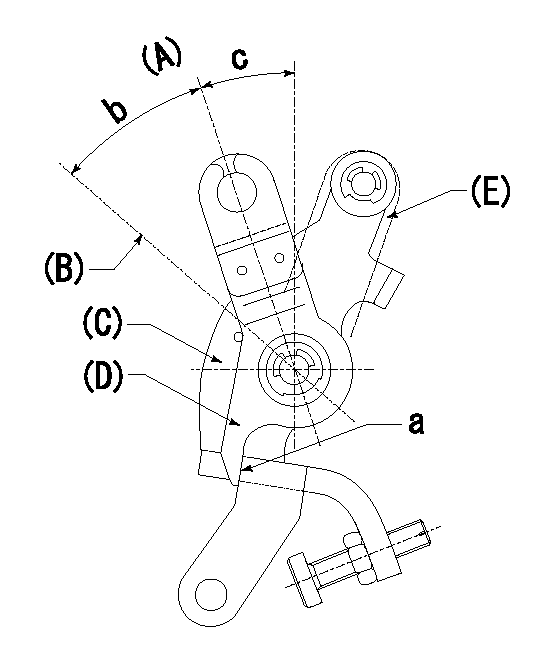

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=40mm

----------

a=18.5deg+-5deg b=(42deg)+-3deg

----------

aa=40mm

----------

a=18.5deg+-5deg b=(42deg)+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

(3)Rack position = approximately ee (speed lever full, speed = ff).

(4)Free (at delivery)

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm ff=0r/min

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm ff=0r/min

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

0000001501 LEVER

(A) Idle

(B) Full speed

(C) Base lever

(D) Accelerator lever

(E) Accelerator lever delivery position

1. Measure speed lever angle

(1)Measure the angle when the accelerator lever (D) contacted the base lever (C) at a.

----------

----------

b=(42deg)+-3deg c=18.5deg+-5deg

----------

----------

b=(42deg)+-3deg c=18.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(2deg)

----------

aa=10deg

----------

a=(2deg)

Information:

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

C175 Engine References

Reference: Troubleshooting, M0069788, "C175 Tier 4 Final Engines for Off-Highway Trucks"Reference: Testing and Adjusting, M0069782, "C175 Tier 4 Final Engines for Off-Highway Trucks"Reference: Disassembly and Assembly, M0080117, "C175 Tier 4 Final Engines for Caterpillar Built Machines"3500 Engine References

Reference: Troubleshooting, M0080819, "3516E Engine for Tier 4 Final 994K Wheel Loaders"Reference: Testing and Adjusting, M0080815, "3516E Engine for Tier 4 Final 994K Wheel Loaders"Reference: Disassembly and Assembly, M0092351, "3516E Engines for Caterpillar Built Machines"Procedure

Note: If failed parts need to be shipped back, please cap off the ports using the caps from the new part.

The DEF injector troubleshooting return form is required and included with failed part returns documenting what was found that led to DEF injector replacement. Attach photos of the DEF injector tip and the mount area along with a Product Status Report to the Service Information Management System claim.

Determine the diagnostic code. ____________________

Troubleshoot the code found using the appropriate troubleshooting manual.

When the troubleshooting procedure requests the DEF quality check, DEF injector resistance measurement, or Dosing Accuracy Test, document the results in Tables 1, 2, and 3.

Table 1

DEF Quality Results

Step Instruction Completed (Yes/No) Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test (include photo of test strip if possible)

3 DEF Concentration Test

% at 20° C (68° F)

Illustration 1 g06371891

Diesel Exhaust Fluid (DEF) Injector Resistance Measurement

Table 2

Injector Resistance Measurement

Step Instruction Completed (Yes/No) Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injector from the applicable harness.

3 Inspect the connector for damage or debris (if damaged take photo).

4 Measure the temperature of the injector (aluminum body). ° C (° F)

5 Connect 2 of the 398-4987 Probe to the DEF injector. The connectors must be used to prevent damage to the DEF injector connector.

6 Measure the resistance of the DEF injector.

Ohms

Table 3

Dosing Accuracy Test

Step Instruction Completed (Yes/No) Units

1 Follow the Testing and Adjusting, Aftertreatment SCR System Dosing - Test.

2 Take a photograph of the DEF injector mount, gasket, and bolts on the SCR inlet prior to removal.

3 Remove the injector from the SCR inlet.

4 Take a photograph of the DEF injector mount on the SCR inlet and the tip of the DEF injector. ° C (° F)

5 Run the DEF System Dosing Accuracy test through Cat ET.

6 Use a beaker to measure the amount of fluid from the dosing test. mL (oz)

7 Repeat the test to verify consistency.

mL (oz)

8 Install the injector back onto the SCR Inlet if instructed per the Troubleshooting Guide Results/Comments

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Have questions with 101608-1070?

Group cross 101608-1070 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

101608-1070

9 400 613 506

ME075716

INJECTION-PUMP ASSEMBLY

6D17

6D17