Information injection-pump assembly

BOSCH

9 400 610 738

9400610738

ZEXEL

101607-9890

1016079890

NISSAN-DIESEL

16700Z5767

16700z5767

Rating:

Service parts 101607-9890 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5519

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

101607-9890

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-5434

as _

Cross reference number

BOSCH

9 400 610 738

9400610738

ZEXEL

101607-9890

1016079890

NISSAN-DIESEL

16700Z5767

16700z5767

Zexel num

Bosch num

Firm num

Name

101607-9890

9 400 610 738

16700Z5767 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FE6B K 14BE INJECTION PUMP ASSY PE6A PE

FE6B K 14BE INJECTION PUMP ASSY PE6A PE

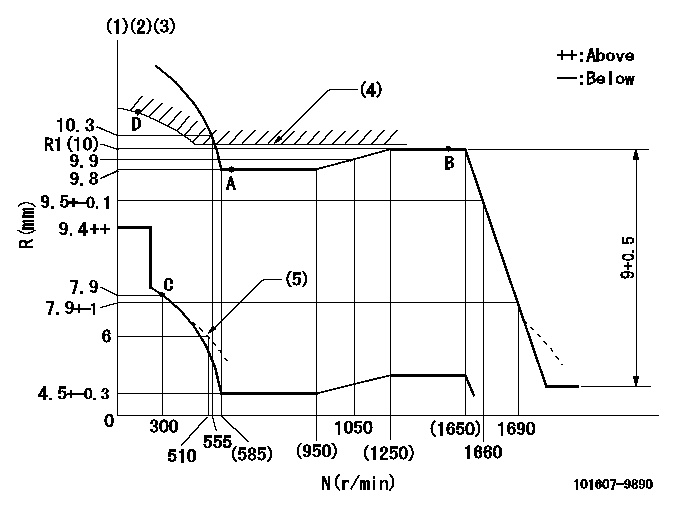

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

58.9

57.9

59.9

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

R1(10)

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

80.6

79.6

81.6

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.9+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

8.3

6.5

10.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

80

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Excess fuel setting for starting: SXL (N = N1)

(5)Damper spring setting

----------

RT=1 TH=1.8mm SXL=R1+0.2mm N1=500r/min

----------

----------

RT=1 TH=1.8mm SXL=R1+0.2mm N1=500r/min

----------

0000000901

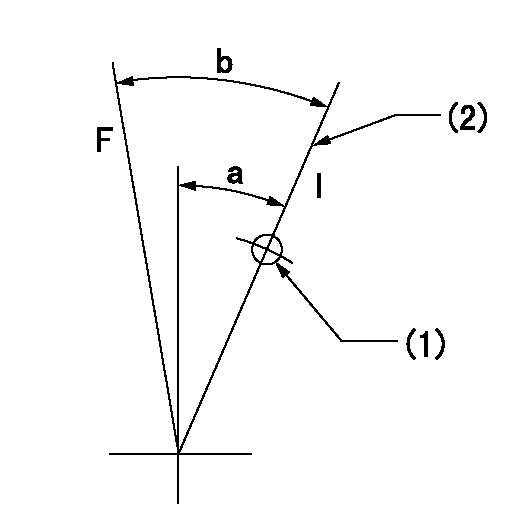

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=70mm

----------

a=18deg+-5deg b=19.5deg+-3deg

----------

aa=70mm

----------

a=18deg+-5deg b=19.5deg+-3deg

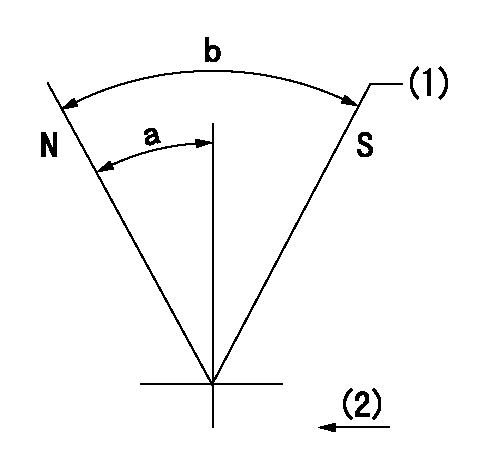

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Drive side

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

----------

aa=20mm

----------

a=40deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.If the crankshaft, gear case and/or crank gear are replaced, it is necessary to perform the injection timing correction procedure. The following steps show how to calculate/determine the new injection timing by measuring angular deviation between the crankshaft TDC and Crank Position sensor detected TDC.Note: Once complete the engine ecm must be reprogrammed with the new injection timing value. Follow all Steps below.Procedure

Illustration 1 g06220080

(1) TC Mark (Flywheel Housing)

(2) TC Mark (Flywheel)

Remove valve cover, injector, and rocker arm. Bring the piston of cylinder 4 to TDC.

Illustration 2 g06220082

(3) Dial Gauge

(4) Valve

(5) O-ring

Remove the #4 exhaust valve bridge arm and valve spring. Insert a small O-ring (5) so the valve (4) does not fall into the cylinder.

Set the dial gauge (3) on the tip of the valve (4).

Illustration 3 g06220083

(6) Tri-sqaure

(7) Flywheel Housing

(8) Flywheel

Illustration 4 g06220087

(7) Flywheel Housing

(8) Flywheel

(9) Reference Line

Turn the flywheel counterclockwise and measure the position where the tip of the valve is highest.

Stop the flywheel at the position where the tip of the valve is the highest. Put a tri-sqaure (6) on the flywheel housing (7) and the flywheel (8) and draw a reference line (9).Do not drop the valve (4) into the cylinder. When measuring the highest position of the tip of the valve do not rotate the flywheel clockwise. If you go past the highest point of the valve, back up the flywheel slightly and measure the highest point of the valve. The reference line (9) indicates the TDC of the crankshaft.

Illustration 5 g06220092

(10) Tester

(11) Crankshaft Position Sensor

Illustration 6 g06220095

(11) Crankshaft Position Sensor

(12) Ground Terminal

(13) Output Terminal

Connect the engine harness and the main switch. Connect battery.Attach the tester (10) to the output terminal (13) and the ground terminal (12) of the crankshaft position sensor (11). Turn the main switch "ON". Turn the flywheel and make sure that the voltage of the crankshaft position sensor goes from 0→ 5 V or 5 → 0 V.

Illustration 7 g06220100

(14) Pulsar Gear

(15) 14th Tooth

(16) Missing Teeth

Rotate the flywheel and align the crankshaft position sensor to the part of the pulsar gear (14) that is missing teeth (16). The 14th tooth (15) from the missing teeth is the standard. Slowly turn the flywheel counterclockwise and stop the flywheel at the point where the needle of the tester changes momentarily from 0→ 5 V, the 14th tooth. That point is where the crankshaft position sensor detects TDC.

Illustration 8 g06220101

(17) Crankshaft TDC

(18) Detection Point of Crankshaft Position Sensor TDC

Illustration 9 g06220104

(19) Interval

Set the tri-square (6) on the reference line (9) on the flywheel housing side and mark the detection point of the crankshaft position sensor TDC (18) on the flywheel.

Measure the interval (19) between the crankshaft TDC (17) and the detection point of the crankshaft position sensor TDC (18).

Calculation of the fuel injection timing correction 1 mm (0.039 inch): 0.342°.Corrected angle = 0.342° X actual interval.

Overwrite the injection timing correction value on the engine ecm registration website refer to REHS9707, "Registering

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.If the crankshaft, gear case and/or crank gear are replaced, it is necessary to perform the injection timing correction procedure. The following steps show how to calculate/determine the new injection timing by measuring angular deviation between the crankshaft TDC and Crank Position sensor detected TDC.Note: Once complete the engine ecm must be reprogrammed with the new injection timing value. Follow all Steps below.Procedure

Illustration 1 g06220080

(1) TC Mark (Flywheel Housing)

(2) TC Mark (Flywheel)

Remove valve cover, injector, and rocker arm. Bring the piston of cylinder 4 to TDC.

Illustration 2 g06220082

(3) Dial Gauge

(4) Valve

(5) O-ring

Remove the #4 exhaust valve bridge arm and valve spring. Insert a small O-ring (5) so the valve (4) does not fall into the cylinder.

Set the dial gauge (3) on the tip of the valve (4).

Illustration 3 g06220083

(6) Tri-sqaure

(7) Flywheel Housing

(8) Flywheel

Illustration 4 g06220087

(7) Flywheel Housing

(8) Flywheel

(9) Reference Line

Turn the flywheel counterclockwise and measure the position where the tip of the valve is highest.

Stop the flywheel at the position where the tip of the valve is the highest. Put a tri-sqaure (6) on the flywheel housing (7) and the flywheel (8) and draw a reference line (9).Do not drop the valve (4) into the cylinder. When measuring the highest position of the tip of the valve do not rotate the flywheel clockwise. If you go past the highest point of the valve, back up the flywheel slightly and measure the highest point of the valve. The reference line (9) indicates the TDC of the crankshaft.

Illustration 5 g06220092

(10) Tester

(11) Crankshaft Position Sensor

Illustration 6 g06220095

(11) Crankshaft Position Sensor

(12) Ground Terminal

(13) Output Terminal

Connect the engine harness and the main switch. Connect battery.Attach the tester (10) to the output terminal (13) and the ground terminal (12) of the crankshaft position sensor (11). Turn the main switch "ON". Turn the flywheel and make sure that the voltage of the crankshaft position sensor goes from 0→ 5 V or 5 → 0 V.

Illustration 7 g06220100

(14) Pulsar Gear

(15) 14th Tooth

(16) Missing Teeth

Rotate the flywheel and align the crankshaft position sensor to the part of the pulsar gear (14) that is missing teeth (16). The 14th tooth (15) from the missing teeth is the standard. Slowly turn the flywheel counterclockwise and stop the flywheel at the point where the needle of the tester changes momentarily from 0→ 5 V, the 14th tooth. That point is where the crankshaft position sensor detects TDC.

Illustration 8 g06220101

(17) Crankshaft TDC

(18) Detection Point of Crankshaft Position Sensor TDC

Illustration 9 g06220104

(19) Interval

Set the tri-square (6) on the reference line (9) on the flywheel housing side and mark the detection point of the crankshaft position sensor TDC (18) on the flywheel.

Measure the interval (19) between the crankshaft TDC (17) and the detection point of the crankshaft position sensor TDC (18).

Calculation of the fuel injection timing correction 1 mm (0.039 inch): 0.342°.Corrected angle = 0.342° X actual interval.

Overwrite the injection timing correction value on the engine ecm registration website refer to REHS9707, "Registering

Have questions with 101607-9890?

Group cross 101607-9890 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Dpico

Mitsubishi

Nissan-Diesel

101607-9890

9 400 610 738

16700Z5767

INJECTION-PUMP ASSEMBLY

FE6B

FE6B