Information injection-pump assembly

BOSCH

9 400 615 763

9400615763

ZEXEL

101607-9801

1016079801

NISSAN-DIESEL

16714Z6017

16714z6017

Rating:

Include in #2:

104746-5400

as _

Cross reference number

BOSCH

9 400 615 763

9400615763

ZEXEL

101607-9801

1016079801

NISSAN-DIESEL

16714Z6017

16714z6017

Zexel num

Bosch num

Firm num

Name

101607-9801

9 400 615 763

16714Z6017 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

MD92 * K

MD92 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8260

Bosch type code

9 430 610 133

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

18

Opening pressure

kgf/cm2

184

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8921

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.8

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

95

93.4

96.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

280

280

280

Average injection quantity

mm3/st.

12

11

13

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.8)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

95

94

96

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.9

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

100.5

96.5

104.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

125

135

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

970--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

920

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

(1000)

Advance angle

deg.

1.5

1

2

Timer adjustment_04

Pump speed

r/min

1160

Advance angle

deg.

1.5

1

2

Timer adjustment_05

Pump speed

r/min

1450

Advance angle

deg.

7

6.5

7.5

Remarks

Finish

Finish

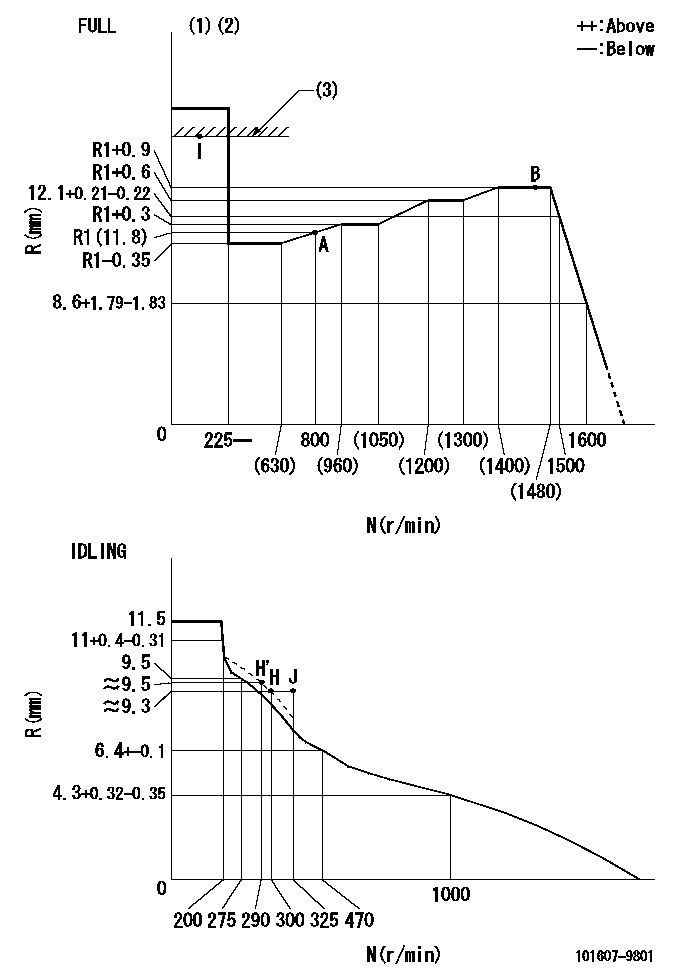

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=M00

----------

----------

T1=M00

----------

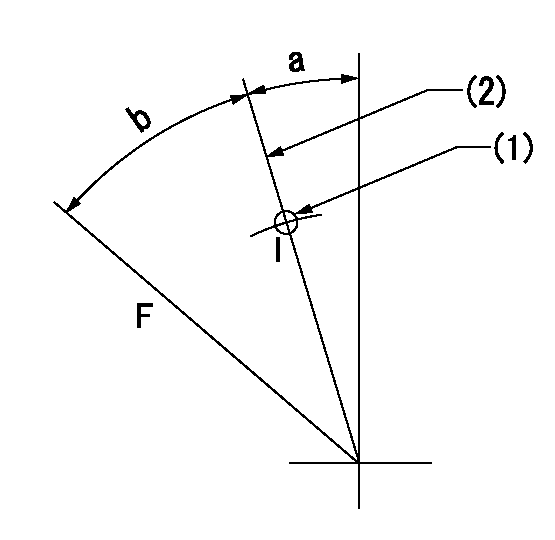

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=36mm

----------

a=6.5deg+-5deg b=(42.5deg)+-3deg

----------

aa=36mm

----------

a=6.5deg+-5deg b=(42.5deg)+-3deg

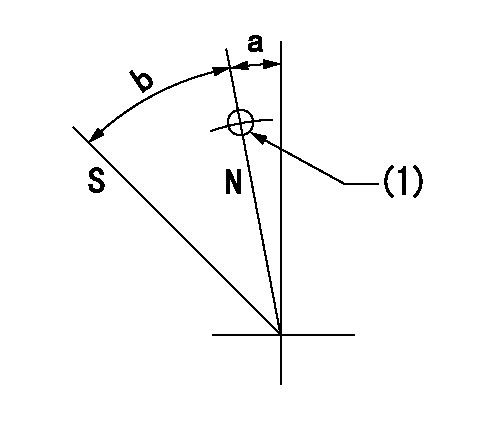

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=5deg+-5deg b=40deg+-5deg

----------

aa=42mm

----------

a=5deg+-5deg b=40deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Illustration 5 g01943178

Coil without debris

Illustration 6 g03351850

(2) Debris on the coil

Inspect the coil for debris.The debris will be visible in the form of metal shavings on the coil. Refer to Illustration. If the coil is covered in soot, use a clean magnet to locate the debris.Note: DO NOT use high-pressure fluid or other cleaning solvents. Debris may be lost during cleaning.

If debris is present and/or an injector is inoperable perform the remaining Steps that are in Special Instruction, REHS3819, "Procedure for Troubleshooting and Cleaning the Oil Rail System for the Hydraulic Electronic Unit Injector (HEUI)". Ensure that the system is flushed through six injector bores, two large and six small plugs.

Illustration 7 g03344174

Close-up view of cylinder head (3) 9S-8003 Plug (4) 214-7567 O-Ring Seal (5) 205-3079 Adapter , and sensor location (if needed)

Cylinder heads that were manufactured prior to January 2006 must relocate the HEUI pressure sensor. Refer to Illustration 7 for the proper location for the HEUI pressure sensor.

Install plug (3) with seal (4) into the port.

Install sensor into the cylinder head at cylinder number 4.

Install sensor into the cylinder head at cylinder number 4, utilizing the following components: 205-3079 Adapter , 214-7567 O-Ring Seal and 214-7568 O-Ring Seal

Illustration 8 g03355201

(6) Fuel pump (7) Gear

Install fuel pump (6) .

Illustration 9 g03345875

(6) Fuel pump (8) Bolts

Position fuel pump (6) and install bolts (8) through the front housing.

Illustration 10 g03355149

View of 242-7032 Engine Oil Lines Gp (9) 6V-9850 Elbow (10) 228-7089 O-Ring Seal (11) 378-8430 Tube As (12) 8C-8988 Elbow

Illustration 11 g03355176

Proper tightening sequence for oil line fittings

Install elbow (9) with o-ring seal (10) onto the fuel pump. Do not tighten the fitting. Refer to Illustration 10

Install elbow (12) with o-ring seal (10) onto the cylinder head port. Do not tighten the fitting.

Install tube assembly (11).

Tighten the fittings to a torque of 45 N m (33 lb ft), that are shown in Illustration 11 using the proper torque sequence.

Illustration 12 g03345035

View of 388-2124 Unit Injection Hydraulic Pump and Mounting Gp (10) 228-7089 O-Ring Seal (13) 068-4174 Elbow (14) 238-5081 O-Ring Seal (15) 6V-8724 Elbow (16) 214-7568 O-Ring Seal (17) 6V-8636 Connector (18) 030-7950 Elbow (19) 238-5082 O-Ring Seal (20) 387-9500 Tube As (21) 387-7159 Tube As (22) 2R-6806 O-Ring Connector (23) 384-0678 or 20R-1636 Unit Injector Hydraulic Pump Gp (24) 9S-8004 Plug

Use the following Steps in order to install the fittings and plugs from the current pump to the new pump. Refer to Illustration 12 for the proper location of the fittings and plugs.

Install the fitting (10) with o-ring seal (16, 17) .

Install fitting (22) with o-ring seal (16) .

Install plug (24) with o-ring seal (16)

Install elbow (15) with o-ring seal (10, 16) onto the fuel pump.

Connect the harness assembly to the connector of the fuel pump.

Install elbow (13) with o-ring seal (14). Refer to Illustration 12

Have questions with 101607-9801?

Group cross 101607-9801 ZEXEL

Nissan-Diesel

101607-9801

9 400 615 763

16714Z6017

INJECTION-PUMP ASSEMBLY

MD92

MD92