Information injection-pump assembly

BOSCH

F 019 Z20 006

f019z20006

ZEXEL

101607-9430

1016079430

Rating:

Include in #1:

101402-7990

as _

Cross reference number

BOSCH

F 019 Z20 006

f019z20006

ZEXEL

101607-9430

1016079430

Zexel num

Bosch num

Firm num

Name

101607-9430

F 019 Z20 006

DPICO

INJECTION-PUMP ASSEMBLY

6D22 Q

6D22 Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

112

109.2

114.8

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.8+-0.5

Pump speed

r/min

450

450

450

Each cylinder's injection qty

mm3/st.

20

17

23

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

112

111

113

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

85

165

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Injection quantity adjustment_05

Adjusting point

F

Rack position

7.3+-0.5

Pump speed

r/min

335

335

335

Average injection quantity

mm3/st.

16

14.5

17.5

Fixing the rack

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

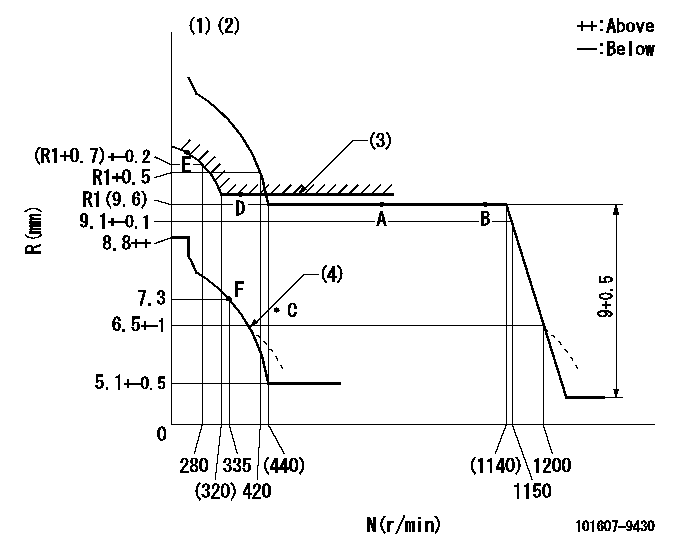

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Microswitch not operating at delivery.

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Excess fuel setting for starting: SXL (N = N1)

(4)Damper spring setting: DL

----------

SXL=(R1+0.1)+0.2mm N1=350r/min DL=6-0.2mm

----------

----------

SXL=(R1+0.1)+0.2mm N1=350r/min DL=6-0.2mm

----------

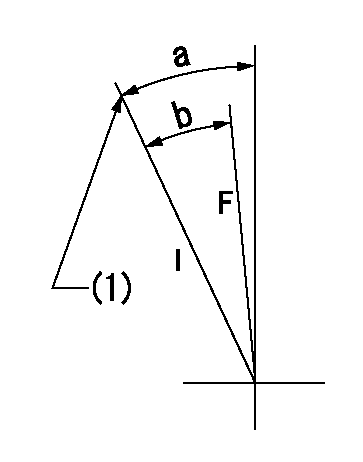

Speed control lever angle

F:Full speed

----------

----------

a=(1deg)+-5deg

----------

----------

a=(1deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=19deg+-5deg b=16.5deg+-3deg

----------

----------

a=19deg+-5deg b=16.5deg+-3deg

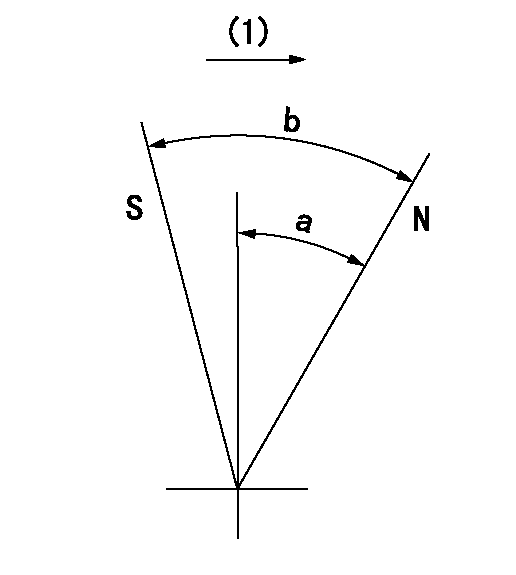

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Drive side

----------

----------

a=54deg+-5deg b=71deg+-5deg

----------

----------

a=54deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(7deg)

----------

aa=15deg

----------

a=(7deg)

Information:

Table 1

Required Parts

Qty Part Number Part Name Former Part Number

1 494-6233 Injector 307-3245(1)

(1) The former part number listed is for reference only and may differ.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

"The improved autolube injector requires a new adjustment sleeve. Follow the procedure below for the selection and adjustment of the sleeve.Changing the Metering Unit

Illustration 1 g06607746

(A) Adjustment Screw

(B) Locknut

(C) Adjustment Sleeve

Table 2

Adjustment Sleeves

Caterpillar Part Number Part Name Output cc Sleeve Color

494-6245 Sleeve 0.25 cc (0.015 cubic inch) Pink

494-6241 Sleeve 0.50 cc (0.030 cubic inch) Red

494-6242 Sleeve 0.750 cc (0.045 cubic inch) Silver

494-6243 Sleeve 1.00 cc (0.06 cubic inch) Gold

494-6244 Sleeve 1.25 cc (0.075 cubic inch) Green The automatic lubrication system offers the ability to change the amount of grease that is supplied per cycle to each grease point. Changing the grease supply amount is completed by adjusting locknut (B) or replacing adjustment sleeve (C) on the injector. See Table 2 for reference.There is a set of color-coded anodized aluminum adjustment sleeves (C) available for various lubrication dispensing amounts. Adjustment sleeves (C) provide an easy way to adjust the output of the injectors and provide a clear indication of the output setting. Adjustment sleeves (C) allow for easy system installation and preventative maintenance.Install adjustment sleeves (C) by doing the following Steps below:

Remove and discard locknut (B).

Place adjustment sleeve (C) on adjustment screw (A).

Tighten adjustment screw (A) to 6.7 N m (60 lb in).

Have questions with 101607-9430?

Group cross 101607-9430 ZEXEL

Nissan-Diesel

Dpico

101607-9430

F 019 Z20 006

INJECTION-PUMP ASSEMBLY

6D22

6D22