Information injection-pump assembly

BOSCH

F 019 Z20 005

f019z20005

ZEXEL

101607-9141

1016079141

Rating:

Include in #2:

104746-5260

as _

Cross reference number

BOSCH

F 019 Z20 005

f019z20005

ZEXEL

101607-9141

1016079141

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

112

109.2

114.8

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.8+-0.5

Pump speed

r/min

450

450

450

Each cylinder's injection qty

mm3/st.

20

17

23

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

112

111

113

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

85

165

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Injection quantity adjustment_05

Adjusting point

F

Rack position

7.3+-0.5

Pump speed

r/min

335

335

335

Average injection quantity

mm3/st.

16

14.5

17.5

Fixing the rack

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

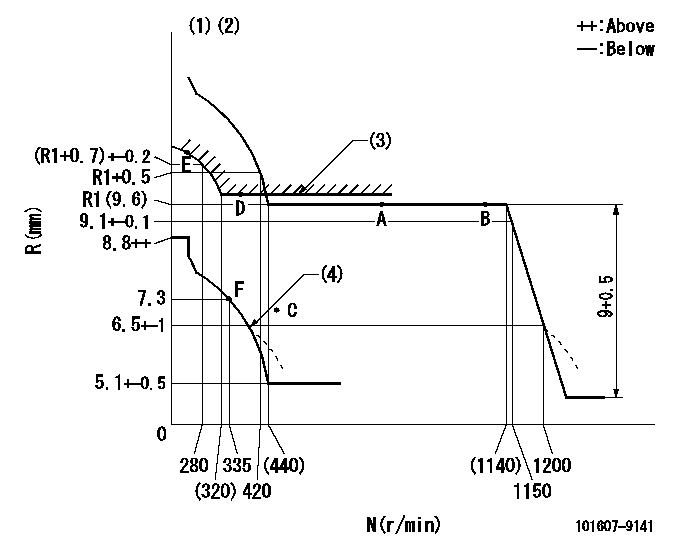

N:Pump speed

R:Rack position (mm)

(1)Microswitch not operating at delivery.

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Excess fuel setting for starting: SXL (N = N1)

(4)Damper spring setting: DL

----------

SXL=(R1+0.1)+0.2mm N1=350r/min DL=6-0.2mm

----------

----------

SXL=(R1+0.1)+0.2mm N1=350r/min DL=6-0.2mm

----------

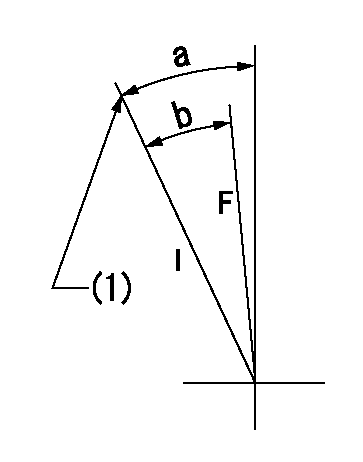

Speed control lever angle

F:Full speed

----------

----------

a=(1deg)+-5deg

----------

----------

a=(1deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=19deg+-5deg b=16.5deg+-3deg

----------

----------

a=19deg+-5deg b=16.5deg+-3deg

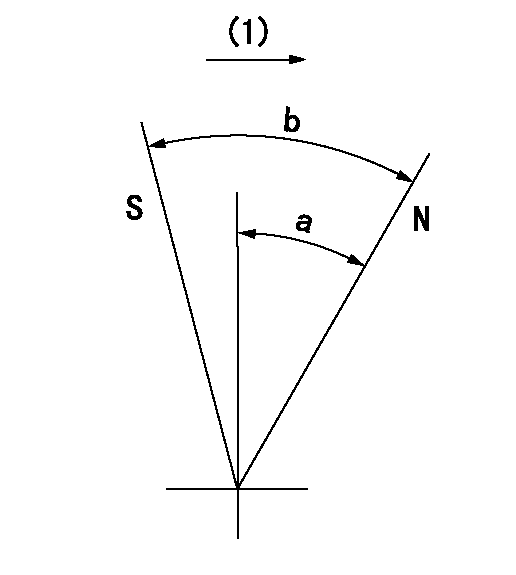

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Drive side

----------

----------

a=54deg+-5deg b=71deg+-5deg

----------

----------

a=54deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(7deg)

----------

aa=15deg

----------

a=(7deg)

Information:

Table 4

Cat Specification for Neat (B100) Biodiesel Blending Fuel

Property Test Method, United States Test Method, International Units Limits, B100 Blending Fuel

Density at 15°C “ASTM D1298” “ISO 3675” g/cm3 0.86-0.90

Viscosity at 40°C “ASTM D445” “ISO 3104” mm2/s (cSt) 1.9-6.0

Flash Point “ASTM D93” “ISO 3679” °C 93 minimum

Pour Point - - - 6 °C (10 °F) minimum below ambient temperature

- Summer “ASTM D97” “ISO 3016” °C

- Winter

Cloud Point “ASTM D2500” °C Report

Sulfur Content(1) “ASTM D5453” “ISO 20846” “ISO 20884” percent weight 0.0015(2) maximum

Distillation - - - -

T90 “ASTM D86” “ISO 3924” °C 360

Cetane Number “ASTM D613” “ISO 5165” % evaporation 45 minimum

Sulfated Ash “ASTM D874” “ISO 3987” or "ISO 6245" percent weight 0.02 maximum

Water and Sediment “ASTM D2709” “ISO 12937” percent volume 0.05 maximum

Water "ASTM D1796" "EN ISO 12937" % m/m -

Copper Corrosion, 3 hours at 50oC “ASTM D130” “ISO 2160” - No. 1

Oxidation Stability “EN 14112” or "EN 15751" “EN 14112” or "EN 15751" hours 3 minimum

Ramsbottom Carbon Residue on 10% bottoms "ASTM D524" “ISO 10370” %-m/m 0.30 maximum

Carbon Residue, Conradson (CCR) “ASTM D4530” - percent weight 0.05 maximum

Esterification "ASTM D 7806" or "ASTM D 7371" “EN 14103” percent volume 97.5 minimum

Total Acid Number “ASTM D664” “EN 14104” mg KOH/g 0.5 maximum

Methanol Content “EN 14110” “EN 14110” percent weight 0.2 maximum

Monoglycerides “ASTM D6584” “EN 14105” percent weight 0.8 maximum

Diglycerides “ASTM D6584” “EN 14105” percent weight 0.2 maximum

Triglycerides “ASTM D6584” “EN 14105” percent weight 0.2 maximum

Free Glycerin “ASTM D6584” “EN 14105” percent weight 0.02 maximum

Total Glycerin “ASTM D6584” “EN 14105” percent weight 0.240 maximum

Phosphorus Content “ASTM D4951” “EN 14107” percent weight 0.001 maximum

Calcium plus Magnesium “EN 14538” “EN 14538” ppm 5 maximum

Sodium plus Potassium “EN 14538” “EN 14538” ppm 5 maximum

Cold Soak Filterability “ASTM D7501” – seconds 360 maximum

Cleanliness “ASTM D7619” “ISO 4406” – (3)

Total contamination "EN 12662" "EN 12662" mg/kg 24 maximum

Appearance "ASTM D4176" - - Clear and Bright

(1) Methods for testing S are based on the sulfur content in diesel fuel used for blending. Consult with the fuel supplier and ensure the correct method has been used

(2) Sulfur level must be per local regulations. Higher S levels may be used where allowed.

(3) Recommended cleanliness level for fuel as dispensed into the engine fuel tank is ISO 18/16/13 or cleaner per the test methods listed. Refer to the contamination control Chapter for more details.Note: Fuels that meet the most current revision level of "ASTM D6751" or "EN 14214" may be used for blending with an acceptable distillate fuel. The conditions, recommendations, and limits that are noted in this Biodiesel section apply.Referenced Documents

Refer to the “Reference Material - Fuel” section of this Special Publication for the reference material for the information in this section.