Information injection-pump assembly

ZEXEL

101607-6892

1016076892

Rating:

Cross reference number

ZEXEL

101607-6892

1016076892

Zexel num

Bosch num

Firm num

Name

101607-6892

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.8

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

80

77.6

82.4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

600

600

600

Each cylinder's injection qty

mm3/st.

10.8

9.2

12.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.8)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

80

79

81

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.35

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

85

81

89

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

55

51

59

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

85

105

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1

0.5

1.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

1

0.5

1.5

Timer adjustment_05

Pump speed

r/min

1400

Advance angle

deg.

7

6.5

7.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=L01

----------

----------

T1=L01

----------

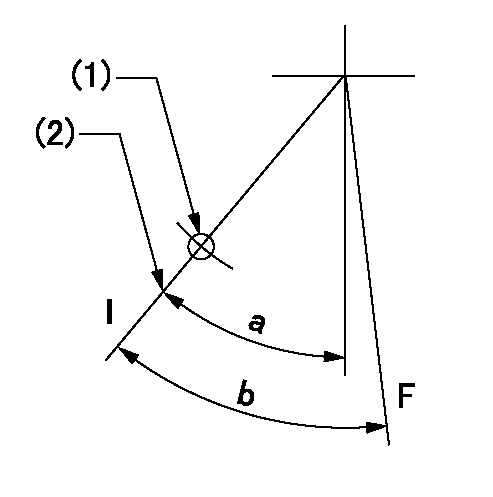

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=41deg+-5deg b=42deg+-3deg

----------

aa=35mm

----------

a=41deg+-5deg b=42deg+-3deg

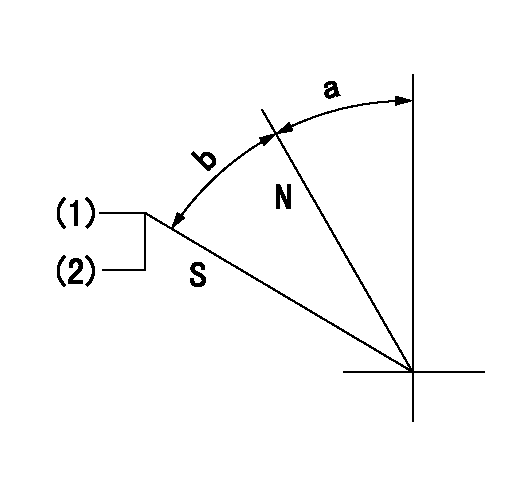

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm

----------

a=32.5deg+-5deg b=25deg+-5deg

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm

----------

a=32.5deg+-5deg b=25deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400r/min Ra=9.2+-0.1mm

----------

----------

N1=400r/min Ra=9.2+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=7deg

----------

a=(4deg)

----------

aa=7deg

----------

a=(4deg)

Information:

Introduction

There have been instances of issues with DEF pumps. After analysis, the cause of the issues has been found as contamination with hydrocarbons.Note: Diesel fuel is an example of a hydrocarbon.The DEF filter is equipped with a compensator located in the center of the filter assembly. If the compensator comes into contact with hydrocarbons, the compensator will swell and is designed to block the filter assembly and protect the DEF pump.Solution

The following procedure is designed to diagnose if the DEF pump has been contaminated with hydrocarbons.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Ensure that the engine is stopped before any servicing or repair is performed. The Diesel Exhaust Fluid (DEF) system must have completed a proper shutdown. Service on the DEF pump prior to completion of a proper shutdown can result in DEF spray and spillage.

Do not turn off the battery disconnect switch until the indicator lamp has turned off. If the switch is turned off when the indicator lamp is illuminated, the Diesel Exhaust Fluid (DEF) system may not shut down properly. If the DEF system does not shut down properly, DEF could freeze and damage the pump and lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Cat Dealer Service Tool Catalog" or refer to Special Publication, PECJ0003, "Cat Shop Supplies and Tools Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

Note: Clean water should be used to wash spilled DEF off machine components and surfaces.Note: Wear gloves when handling the DEF filter.

Illustration 1 g06278274

(1) Protective cover

Remove protective cover (1).

Illustration 2 g06278289

(2) DEF filter cap

Use a suitable tool to remove DEF filter cap (2).

Illustration 3 g06278325

(3) Compensator

With the filter installed in the DEF pump, carefully remove compensator (3).

Illustration 4 g06614423

(A) 85 mm (3.3 inch)

(B) 17 mm (0.7 inch)

Check the measurements of compensator (3). Check if the measurements are greater than specified in Illustration 4. This condition indicates that the DEF pump is contaminated with hydrocarbons.

If the measurements indicate contamination, replace the DEF pump filter. Refer to Operation and Maintenance Manual, Diesel Exhaust Fluid Filter - Replace.Flush the DEF tank. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush.

If the measurements are within the specification, continue to follow the appropriate troubleshooting procedure to determine if the DEF pump has a fault.

There have been instances of issues with DEF pumps. After analysis, the cause of the issues has been found as contamination with hydrocarbons.Note: Diesel fuel is an example of a hydrocarbon.The DEF filter is equipped with a compensator located in the center of the filter assembly. If the compensator comes into contact with hydrocarbons, the compensator will swell and is designed to block the filter assembly and protect the DEF pump.Solution

The following procedure is designed to diagnose if the DEF pump has been contaminated with hydrocarbons.

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Ensure that the engine is stopped before any servicing or repair is performed. The Diesel Exhaust Fluid (DEF) system must have completed a proper shutdown. Service on the DEF pump prior to completion of a proper shutdown can result in DEF spray and spillage.

Do not turn off the battery disconnect switch until the indicator lamp has turned off. If the switch is turned off when the indicator lamp is illuminated, the Diesel Exhaust Fluid (DEF) system may not shut down properly. If the DEF system does not shut down properly, DEF could freeze and damage the pump and lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Cat Dealer Service Tool Catalog" or refer to Special Publication, PECJ0003, "Cat Shop Supplies and Tools Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

Note: Clean water should be used to wash spilled DEF off machine components and surfaces.Note: Wear gloves when handling the DEF filter.

Illustration 1 g06278274

(1) Protective cover

Remove protective cover (1).

Illustration 2 g06278289

(2) DEF filter cap

Use a suitable tool to remove DEF filter cap (2).

Illustration 3 g06278325

(3) Compensator

With the filter installed in the DEF pump, carefully remove compensator (3).

Illustration 4 g06614423

(A) 85 mm (3.3 inch)

(B) 17 mm (0.7 inch)

Check the measurements of compensator (3). Check if the measurements are greater than specified in Illustration 4. This condition indicates that the DEF pump is contaminated with hydrocarbons.

If the measurements indicate contamination, replace the DEF pump filter. Refer to Operation and Maintenance Manual, Diesel Exhaust Fluid Filter - Replace.Flush the DEF tank. Refer to Systems Operation, Testing and Adjusting, Diesel Exhaust Fluid Tank - Flush.

If the measurements are within the specification, continue to follow the appropriate troubleshooting procedure to determine if the DEF pump has a fault.

Have questions with 101607-6892?

Group cross 101607-6892 ZEXEL

101607-6892

INJECTION-PUMP ASSEMBLY