Information injection-pump assembly

ZEXEL

101607-6703

1016076703

Rating:

Cross reference number

ZEXEL

101607-6703

1016076703

Zexel num

Bosch num

Firm num

Name

101607-6703

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

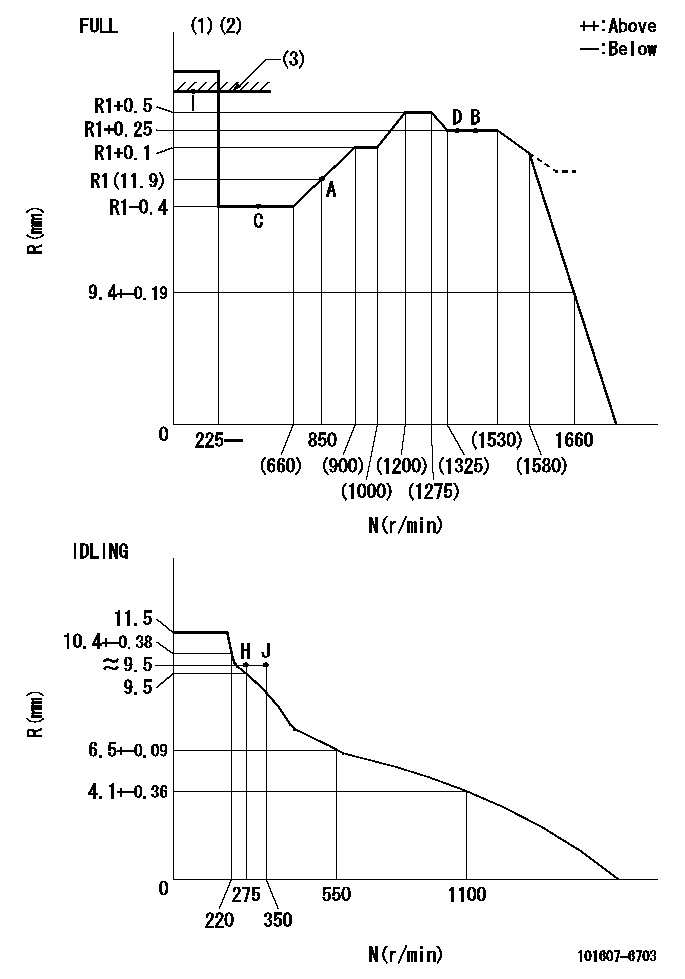

Injection quantity adjustment

Adjusting point

-

Rack position

11.9

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

86.5

83.9

89.1

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

600

600

600

Each cylinder's injection qty

mm3/st.

10.8

9.2

12.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.9)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

86.5

85.5

87.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.25

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

88

84

92

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.4

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

71.5

67.5

75.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

85

105

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1

0.5

1.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

1

0.5

1.5

Timer adjustment_05

Pump speed

r/min

1400

Advance angle

deg.

7

6.5

7.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=J63

----------

----------

T1=J63

----------

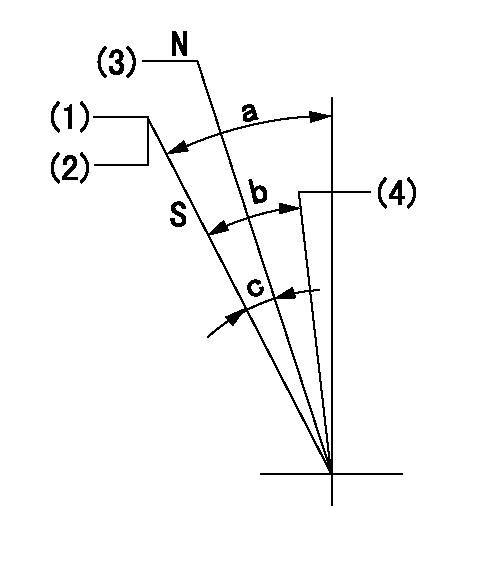

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=42deg+-3deg

----------

----------

a=18.5deg+-5deg b=42deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

(3)Rack position = approximately ee.

(4)Free (at delivery)

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

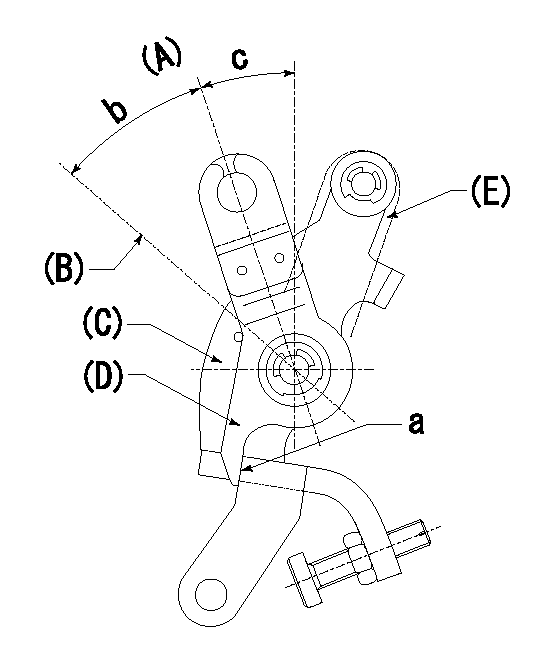

0000001501 LEVER

(A) Idle

(B) Full speed

(C) Base lever

(D) Accelerator lever

(E) Accelerator lever delivery position

1. Measure speed lever angle

(1)Measure the angle when the accelerator lever (D) contacted the base lever (C) at a.

----------

----------

b=42deg+-3deg c=18.5deg+-5deg

----------

----------

b=42deg+-3deg c=18.5deg+-5deg

0000001601 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=3.57+-0.02V V2f=3+0.05V V2i=1+0.1V

----------

----------

V1=3.57+-0.02V V2f=3+0.05V V2i=1+0.1V

----------

0000001701 MICRO SWITCH

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

1. Microswitch adjustment (OPEN type)

Confirm with the lever angle at full.

(1)Speed N1

(2)Rack position Ra

2. Idle side microswitch adjustment (OPEN type)

Confirm with the lever angle at idle.

(1)Speed N2

(2)Rack position Rb

----------

N1=1675r/min Ra=8.5+-0.1mm N2=275r/min Rb=9.7+-0.1mm

----------

----------

N1=1675r/min Ra=8.5+-0.1mm N2=275r/min Rb=9.7+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=7deg

----------

a=(3deg)

----------

aa=7deg

----------

a=(3deg)

Information:

When all details are filled in, select "Submit".Note: Two labels and a serial number plate will be sent to the dealer address. If two labels are not received, contact Global_Engine_Marking.

Illustration 14 g03159376

Install the new emissions certification film (6), information label (7), and serial number plate on the cylinder block according to the installation instructions received with the labels and plate.Note: Destroy the old emissions certification film and serial number plate.Operation and Maintenance information

There are several specific messages on this machine. The exact location of the messages and the description of the messages are reviewed in this section. Become familiarized with all messages.Make sure that all of the messages are legible. Clean the messages or replace the messages if you cannot read the words. Replace the illustrations if the illustrations are not legible. When you clean the messages, use a cloth, water, and soap. Do not use solvent, gasoline, or other harsh chemicals to clean the messages. Solvents, gasoline, or harsh chemicals could loosen the adhesive that secures the messages. Loose adhesive will allow the messages to fall.Replace any message that is damaged, or missing. If a message is attached to a part that is replaced, install a message on the replacement part. Any Cat® dealer can provide new messages.

Illustration 15 g03518298

Location of films (1) Engine Oil film (2) Diesel Fuel Requirements filmEngine Oil (1)

This film is located on the engine oil filler tube on the right side of the machine.

Illustration 16 g02448560

Cat® DEO-ULS oils and oils that satisfy the "API CJ-4"and/or "ACEA E9" requirements are required for engines that are equipped with a diesel particulate filter.Diesel Fuel Requirements (2)

This film is located by the fuel filler on the right side of the machine.

Illustration 17 g03619316

Use Ultralow Sulfur Diesel (ULSD) fuel.The Environmental Protection Agency (EPA) defines Ultra-Low Sulfur Diesel (ULSD - S15) as "a diesel fuel with a sulfur content not to exceed 15 parts per million (ppm(mg/kg)) or 0.0015 percent by weight". Engines are equipped with exhaust after-treatment systems are designed to run on ULSD only. Use of LSD or fuels higher than 15 ppm (mg/kg) sulfur in these engines will reduce engine efficiency and engine durability. Damage to the emissions control systems and/or shortened service interval will occur. Failures that result form the use of fuels are not Caterpillar factory defects. Therefore the cost of repairs would not be covered by a Caterpillar warranty.In Europe, ultra low sulfur diesel fuel will have a maximum of 0.0010 percent (10 ppm(mg/kg)) sulfur and is typically referred to as "sulfur-free". This sulfur level is defined in European Standard "EN 590:2004".Lubricant Viscosities - Fluids Recommendations

Engine Oil

Cat® oils have been developed and tested to provide the full performance and life that has been designed and built into Cat® engines.

Illustration 18 g02448560

Cat® DEO-ULS or oils that meet the Cat® ECF-3 specification and the API CJ-4 are required for use in the applications listed below. Cat® DEO-ULS and oils meeting Cat® ECF-3 specification and the API CJ-4 and ACEA E9 oil categories have been developed with limited sulfated ash,

Have questions with 101607-6703?

Group cross 101607-6703 ZEXEL

101607-6703

INJECTION-PUMP ASSEMBLY