Information injection-pump assembly

BOSCH

9 400 615 689

9400615689

ZEXEL

101607-6280

1016076280

MITSUBISHI

ME150462

me150462

Rating:

Service parts 101607-6280 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056371

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

101607-6280

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-6801

as _

Cross reference number

BOSCH

9 400 615 689

9400615689

ZEXEL

101607-6280

1016076280

MITSUBISHI

ME150462

me150462

Zexel num

Bosch num

Firm num

Name

101607-6280

9 400 615 689

ME150462 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22 * K 14BF INJECTION PUMP ASSY PE6AD PE

6D22 * K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.9

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

120

116.6

123.4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

18.5

15.7

21.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.9)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

120

119

121

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9.9)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

123.7

121.2

126.2

Difference in delivery

mm3/st.

9

9

9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

100

180

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

0.9

0.4

1.4

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

3

2.5

3.5

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4

4

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

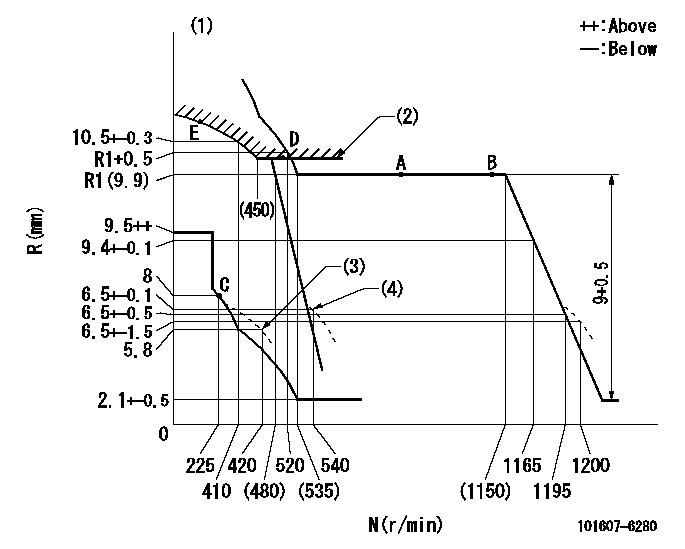

Test data Ex:

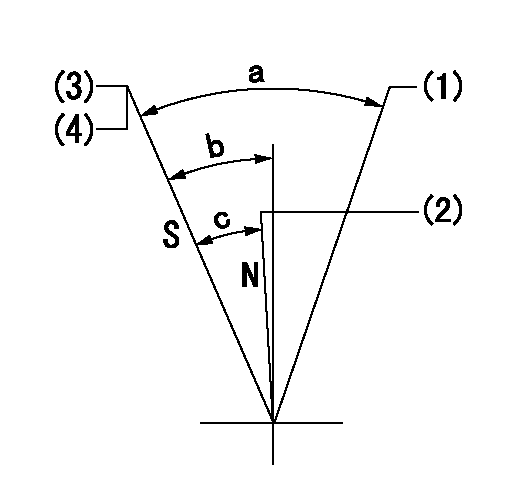

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Excess fuel setting for starting: SXL

(3)Damper spring setting

(4)When air cylinder is operating.

----------

SXL=R1+0.2mm

----------

----------

SXL=R1+0.2mm

----------

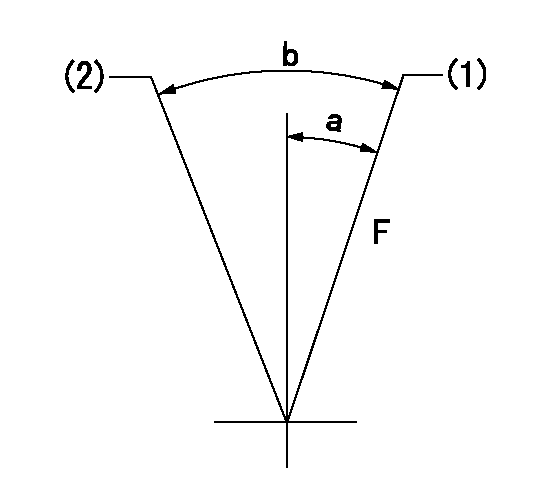

Speed control lever angle

F:Full speed

(1)Set the pump speed at aa

(2)Set the pump speed at bb.

----------

aa=1165r/min bb=540r/min

----------

a=10deg+-5deg b=(15deg)+-5deg

----------

aa=1165r/min bb=540r/min

----------

a=10deg+-5deg b=(15deg)+-5deg

0000000901

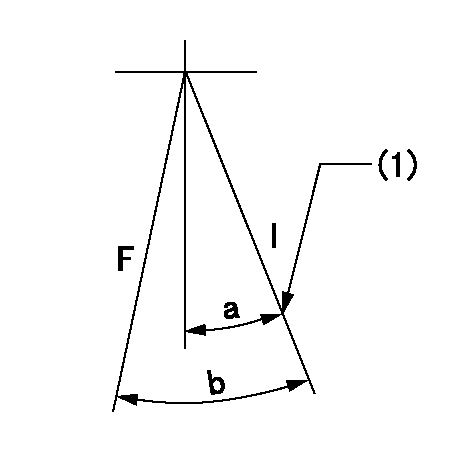

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=21deg+-5deg b=28.5deg+-3deg

----------

----------

a=21deg+-5deg b=28.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Free (at delivery)

(2)Rack position = aa

(3)Rack position bb

(4)Stopper bolt setting

----------

aa=13.5mm bb=6-0.5mm

----------

a=(52deg) b=30deg+7deg-5deg c=24deg+-5deg

----------

aa=13.5mm bb=6-0.5mm

----------

a=(52deg) b=30deg+7deg-5deg c=24deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=7.3+-0.1mm

----------

----------

N1=325r/min Ra=7.3+-0.1mm

----------

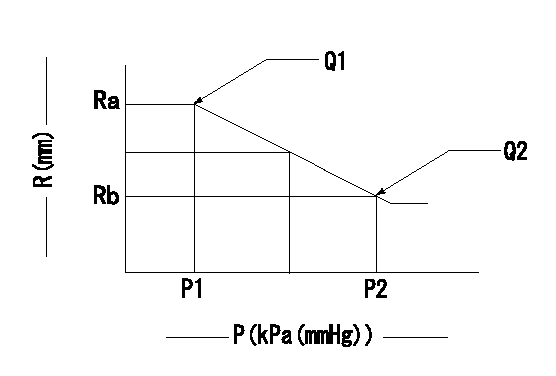

0000001601 ACS

Aneroid compensator adjustment

(1)Adjust the clearance between the aneroid compensator's main body and the push rod to L1.

(2)Pump speed N1 at load lever's full position.

(3)Screw in the aneroid compensator body to obtain the performance shown in the graph above.

----------

L1=0.1~0.5mm N1=700r/min

----------

Ra=9.9mm Rb=(9.2)mm P1=(88.6)kPa((665)mmHg) P2=69+-0.7kPa(518+-5mmHg) Q1=120+-1cm3/1000st Q2=100.5+-1cm3/1000st

----------

L1=0.1~0.5mm N1=700r/min

----------

Ra=9.9mm Rb=(9.2)mm P1=(88.6)kPa((665)mmHg) P2=69+-0.7kPa(518+-5mmHg) Q1=120+-1cm3/1000st Q2=100.5+-1cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

- Generator Monitoring SystemI/O - Input/OutputMMS - Marine Monitoring SystemMMS II - Marine Monitoring System IIPLC - Programmable Logic ControllerThe 203-7811 Engine Monitoring Control Group is the service replacement for the 146-3117 Monitoring Control and the 162-1662 Monitoring Control that are used in MMS. The 203-7811 Engine Monitoring Control Group uses Wonderware as the "Graphic Display Application".The 203-7810 Engine Monitoring Control Group is the optional monitor that is used in the MMS II and the GMS. The 203-7810 Engine Monitoring Control Group uses the RSView as the "Graphic Display Application".When these engine monitoring control groups are used as service replacements in the field, use the procedure that follows to register the software to the user. This procedure can be done when the engine monitoring control group is connected to the PLC. This procedure can also be done when the engine monitoring control group is not connected to the PLC.

Connect a keyboard that is compatible with the PS/2 style of connector. Connect electrical power to the monitor.

Turn on the power.

When you are prompted, accept the license agreement. Press the "Next" button.

Enter the Microsoft Windows NT product identification number. This number is located on the right side of the computer. Press "Next".

When the message indicates that the system could not complete the login, select "OK".

Input "Administrator" for the login username. Input "3600" for the login password.

After a successful login as "Administrator", do one of the items that follow:

Restart the computer.

Close all of the programs and use a different login username.

When the message indicates that the system could not complete the login, select "OK".

Input "Operator" for the login username. Input "password" for the login password.

After a successful login as "Operator", one of the items that follow will occur:

If a 203-7811 Engine Monitoring Control Group is used, the Wonderware I/O Server and the Window Viewer will be started.

If a 203-7810 Engine Monitoring Control Group is used, the RSView Runtime will be started.

Remove the keyboard. The setup is complete.In applications that use Wonderware or RSView, the engine monitoring control group must be connected to the PLC in order for the data to be displayed.After a successful login to the "Operator" account, the computer will automatically start and the computer will start the application in the "Operator" account. The automatic start-up can be bypassed by doing the operations that follow:

Attach a keyboard.

Hold the "shift" key in the down position while the start-up of the computer is initiated.

Connect a keyboard that is compatible with the PS/2 style of connector. Connect electrical power to the monitor.

Turn on the power.

When you are prompted, accept the license agreement. Press the "Next" button.

Enter the Microsoft Windows NT product identification number. This number is located on the right side of the computer. Press "Next".

When the message indicates that the system could not complete the login, select "OK".

Input "Administrator" for the login username. Input "3600" for the login password.

After a successful login as "Administrator", do one of the items that follow:

Restart the computer.

Close all of the programs and use a different login username.

When the message indicates that the system could not complete the login, select "OK".

Input "Operator" for the login username. Input "password" for the login password.

After a successful login as "Operator", one of the items that follow will occur:

If a 203-7811 Engine Monitoring Control Group is used, the Wonderware I/O Server and the Window Viewer will be started.

If a 203-7810 Engine Monitoring Control Group is used, the RSView Runtime will be started.

Remove the keyboard. The setup is complete.In applications that use Wonderware or RSView, the engine monitoring control group must be connected to the PLC in order for the data to be displayed.After a successful login to the "Operator" account, the computer will automatically start and the computer will start the application in the "Operator" account. The automatic start-up can be bypassed by doing the operations that follow:

Attach a keyboard.

Hold the "shift" key in the down position while the start-up of the computer is initiated.

Have questions with 101607-6280?

Group cross 101607-6280 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

101607-6280

9 400 615 689

ME150462

INJECTION-PUMP ASSEMBLY

6D22

6D22