Information injection-pump assembly

BOSCH

9 400 615 683

9400615683

ZEXEL

101607-6221

1016076221

MITSUBISHI

ME076382

me076382

Rating:

Service parts 101607-6221 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7(160)/21.6(220)

14.

NOZZLE

Include in #1:

101607-6221

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-6890

as _

Cross reference number

BOSCH

9 400 615 683

9400615683

ZEXEL

101607-6221

1016076221

MITSUBISHI

ME076382

me076382

Zexel num

Bosch num

Firm num

Name

101607-6221

9 400 615 683

ME076382 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D16 K

6D16 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.7

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

77.4

75.1

79.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

800

800

800

Each cylinder's injection qty

mm3/st.

10.8

9.2

12.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.7)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

77.4

76.4

78.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.55

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

87.7

83.7

91.7

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.4

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

56

52

60

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

E

Rack position

(R1+0.5)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

87.6

83.6

91.6

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

91

81

101

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1080

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2.5

2.5

2.5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

1390

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

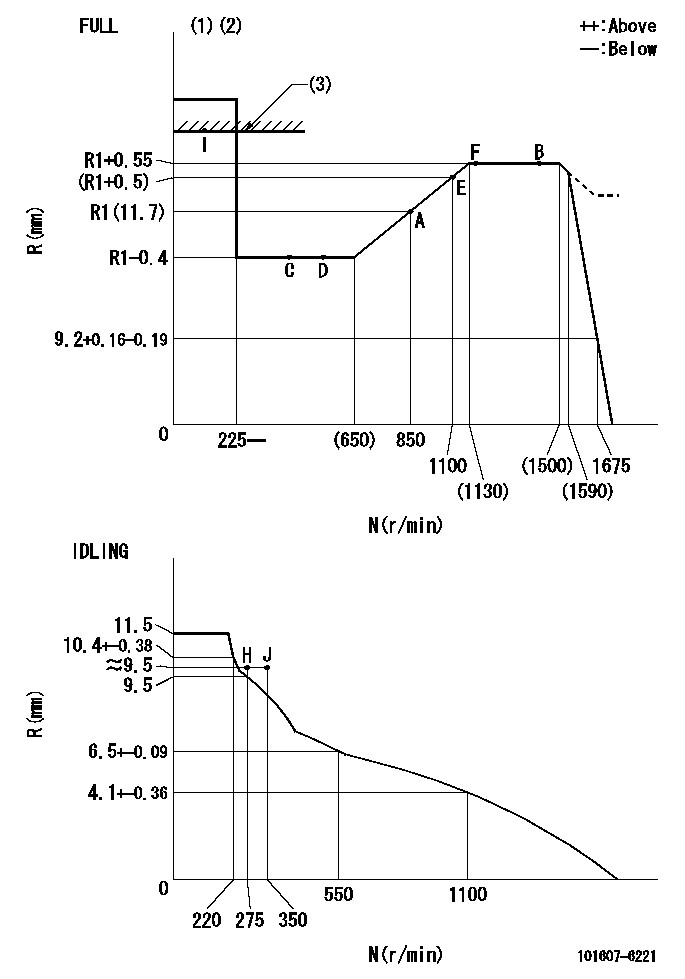

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=H50

----------

----------

T1=H50

----------

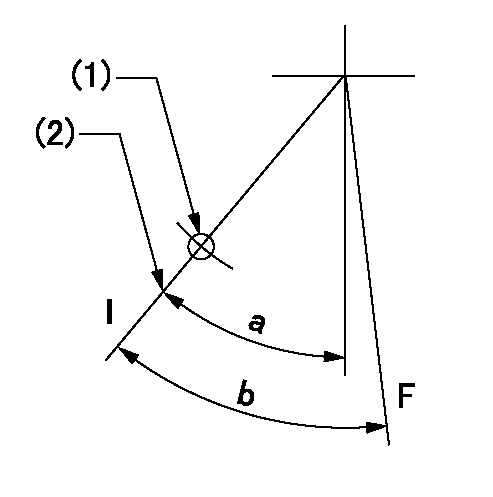

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=41deg+-5deg b=(42deg)+-3deg

----------

aa=35mm

----------

a=41deg+-5deg b=(42deg)+-3deg

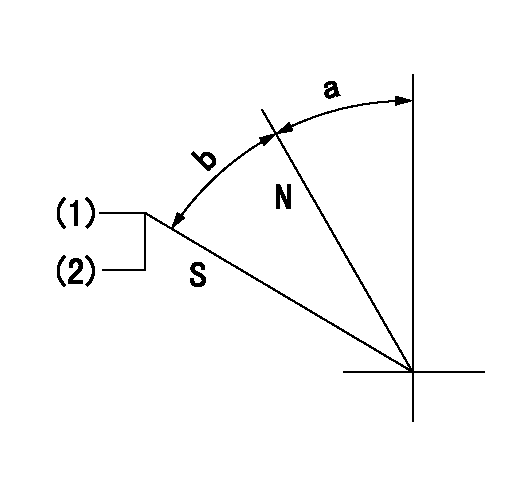

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm

----------

a=32.5deg+-5deg b=25deg+-5deg

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm

----------

a=32.5deg+-5deg b=25deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400r/min Ra=9.2+-0.1mm

----------

----------

N1=400r/min Ra=9.2+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(3deg)

----------

aa=10deg

----------

a=(3deg)

Information:

Troubleshooting the -5 Cylinder Injector : Current Below Normal Code

Illustration 1 g01336507

Schematic for the 16-cylinder injectors

Illustration 2 g01336555

Schematic for the 20-cylinder injectors

Electrical Shock Hazard. The unit injector system uses 90 - 120 volts. The ECM sends this signal to the unit injectors. Do not come in contact with the unit injector harness connector while the engine is operating. Failure to follow this instruction could resulting in personal injury or death.

Table 3

Troubleshooting Test Steps Value Result

A. Check for an Intermittent High Resistance Short Circuit to Ground.

1. Disconnect the rail harness from the ECM. Inspect the connectors and terminals for moisture, corrosion, and other damage. Inspect the condition of the wires. Perform a

45 N (10 lb) pull test on the wires.

Connectors and wiring Result: A problem with the connectors or wiring is found..

Repair the parts, as needed.

Stop

Result: The connectors and wiring appear to be OK.

Proceed to the next test step.

2. On the rail harness, locate any one of the three terminals for the two injectors that have the -5 code.

3. Measure the resistance from the terminal on the rail harness to chassis ground. Ensure that the ground connection is good.

Illustration 1 g01336507

Schematic for the 16-cylinder injectors

Illustration 2 g01336555

Schematic for the 20-cylinder injectors

Electrical Shock Hazard. The unit injector system uses 90 - 120 volts. The ECM sends this signal to the unit injectors. Do not come in contact with the unit injector harness connector while the engine is operating. Failure to follow this instruction could resulting in personal injury or death.

Table 3

Troubleshooting Test Steps Value Result

A. Check for an Intermittent High Resistance Short Circuit to Ground.

1. Disconnect the rail harness from the ECM. Inspect the connectors and terminals for moisture, corrosion, and other damage. Inspect the condition of the wires. Perform a

45 N (10 lb) pull test on the wires.

Connectors and wiring Result: A problem with the connectors or wiring is found..

Repair the parts, as needed.

Stop

Result: The connectors and wiring appear to be OK.

Proceed to the next test step.

2. On the rail harness, locate any one of the three terminals for the two injectors that have the -5 code.

3. Measure the resistance from the terminal on the rail harness to chassis ground. Ensure that the ground connection is good.

Have questions with 101607-6221?

Group cross 101607-6221 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

101607-6221

9 400 615 683

ME076382

INJECTION-PUMP ASSEMBLY

6D16

6D16