Information injection-pump assembly

BOSCH

F 019 Z10 380

f019z10380

ZEXEL

101607-6164

1016076164

Rating:

Service parts 101607-6164 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7(160)/21.6(220)

14.

NOZZLE

Cross reference number

BOSCH

F 019 Z10 380

f019z10380

ZEXEL

101607-6164

1016076164

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.7

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

77.4

75.1

79.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.5+-0.5

Pump speed

r/min

800

800

800

Each cylinder's injection qty

mm3/st.

10.8

9.2

12.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.7)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

77.4

76.4

78.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.55

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

87.7

83.7

91.7

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.4

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

56

52

60

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

E

Rack position

(R1+0.5)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

87.6

83.6

91.6

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

91

81

101

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1080

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2.5

2.5

2.5

Timer adjustment_03

Pump speed

r/min

1390

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

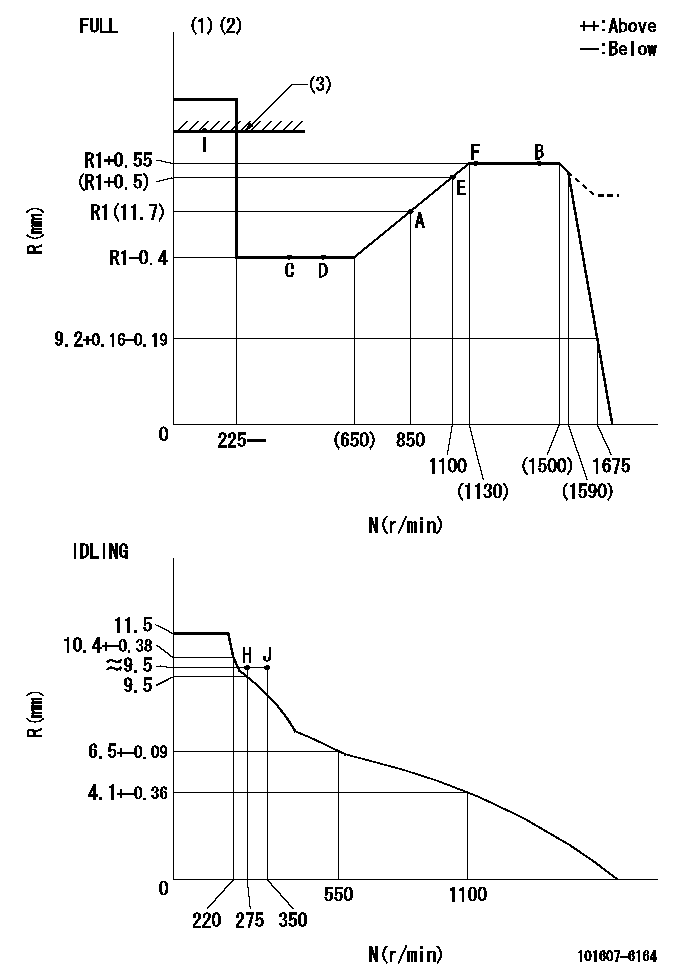

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=H50

----------

----------

T1=H50

----------

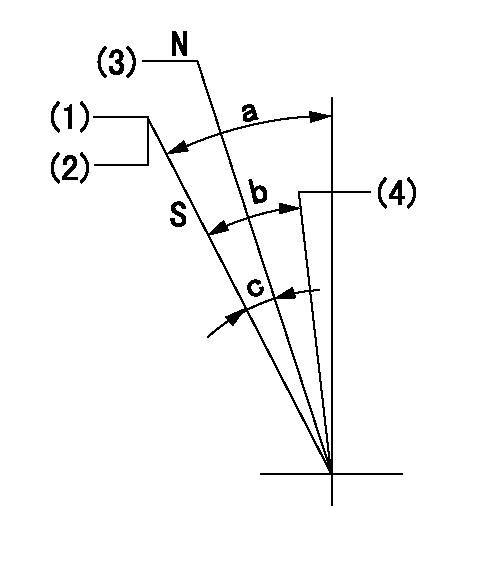

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=(42deg)+-3deg

----------

----------

a=18.5deg+-5deg b=(42deg)+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

(3)Rack position = approximately ee.

(4)Free (at delivery)

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

----------

aa=1450r/min bb=7.2-0.5mm cc=275r/min dd=(8.8)mm ee=15mm

----------

a=36.5deg+-5deg b=(25deg) c=13deg+-5deg

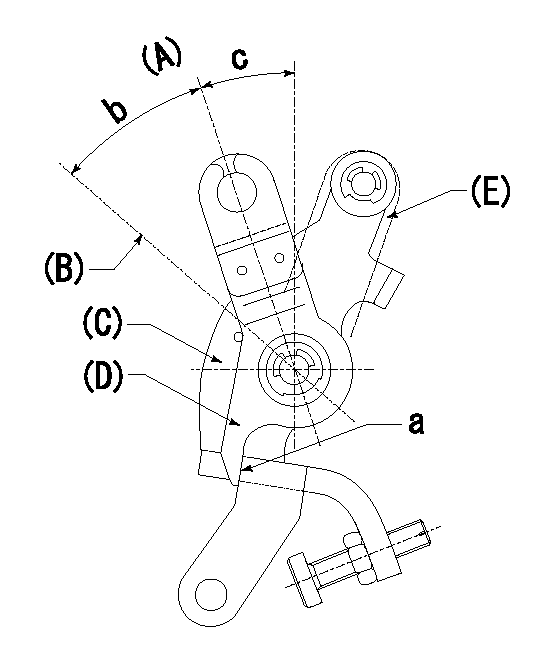

0000001501 LEVER

(A) Idle

(B) Full speed

(C) Base lever

(D) Accelerator lever

(E) Accelerator lever delivery position

1. Measure speed lever angle

(1)Measure the angle when the accelerator lever (D) contacted the base lever (C) at a.

----------

----------

b=(42deg)+-3deg c=18.5deg+-5deg

----------

----------

b=(42deg)+-3deg c=18.5deg+-5deg

0000001601 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=3.57+-0.02V V2f=3+0.05V V2i=1+0.1V

----------

----------

V1=3.57+-0.02V V2f=3+0.05V V2i=1+0.1V

----------

0000001701 MICRO SWITCH

Adjust the bolt to obtain the following lever position when the micro-switch is OFF.

1. Microswitch adjustment (OPEN type)

Confirm with the lever angle at full.

(1)Speed N1

(2)Rack position Ra

----------

N1=1675r/min Ra=8.5+-0.1mm

----------

----------

N1=1675r/min Ra=8.5+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(3deg)

----------

aa=10deg

----------

a=(3deg)

Information:

You should follow the instructions in Operations and Maintenance Manual, "Initialization for Direct Connection" before you connect by a modem. The user can verify proper operation of the CCM at the location. The user can also become familiar with the CCM. Make sure that the following equipment is available:

A personal computer with a terminal emulator software program. Examples of terminal emulators include Procomm, PC-VT, or Terminal under the Accessories window in Microsoft Windows. Refer to "Caterpillar CCM PC For Windows: Getting Started Manual" for specifications on the PC. The user is responsible for understanding the operation of the PC.

The proper RS-232C cables are required for the particular installation. An RS-232C cable must be temporarily connected from the PC to the Answering Modem. Refer to Operation and Maintenance Manual, "RS-232C Cable Requirements".

The two modems must support the Hayes AT command set. This is necessary for both the Answering Modem and the Originating Modem.

The CCM PC For Windows software is required. This software is available from Caterpillar.Note: Some personal computers will have an internal modem. The internal modem may be used as the Originating Modem. The internal modem must be compatible with the Answering Modem. Consult the instructions for the two modems.ProcedurePerform the following procedure in order to initialize communication with the CCM and the Answering Modem. The Originating Modem is set up later by the PC software.Note: In the following steps, the PC and the modems should be turned OFF before you change the cables on the serial ports. When power is reapplied, the modem must be powered up first.

The CCM should be installed with all of the wiring. Refer to the Operations and Maintenance Manual, "General Wiring Diagram" and "RS-232C Cable Requirements".

Determine the parameters for communication for the installation. The RS-232C default rate of communication (bits per second or bps) is 9600. The remaining default settings from the factory are no parity, 8 data bits, and 1 stop bit. These parameters will work well in most installations. Use the Operation and Maintenance Manual, "Communication Parameters - Identify" to determine the parameters of communication that are stored in the CCM.Note: The RS-232C serial port communication baud rate is often referred to as the DTE speed. The phone port communication rate is often referred to as the DCE speed.

Connect the RS-232C port of the Answering Modem directly to the RS-232C port of the PC. This connection is temporary. This connection is required to set up the Answering Modem.

Use the terminal emulator on the PC to set the parameters for communication for the RS-232C port. Use the same values that were chosen in step 2.

Several commands must be sent to the Answering Modem that set the parameters for communication to the proper values. The examples in Table 1 are Hayes AT commands. Actual command sets vary widely between modem manufacturers. Consult the manual for the modem. Save these parameters to the modem memory.

Table 1

Typical Answering Modem Setup Commands

Item Explanation Command Example Command

A personal computer with a terminal emulator software program. Examples of terminal emulators include Procomm, PC-VT, or Terminal under the Accessories window in Microsoft Windows. Refer to "Caterpillar CCM PC For Windows: Getting Started Manual" for specifications on the PC. The user is responsible for understanding the operation of the PC.

The proper RS-232C cables are required for the particular installation. An RS-232C cable must be temporarily connected from the PC to the Answering Modem. Refer to Operation and Maintenance Manual, "RS-232C Cable Requirements".

The two modems must support the Hayes AT command set. This is necessary for both the Answering Modem and the Originating Modem.

The CCM PC For Windows software is required. This software is available from Caterpillar.Note: Some personal computers will have an internal modem. The internal modem may be used as the Originating Modem. The internal modem must be compatible with the Answering Modem. Consult the instructions for the two modems.ProcedurePerform the following procedure in order to initialize communication with the CCM and the Answering Modem. The Originating Modem is set up later by the PC software.Note: In the following steps, the PC and the modems should be turned OFF before you change the cables on the serial ports. When power is reapplied, the modem must be powered up first.

The CCM should be installed with all of the wiring. Refer to the Operations and Maintenance Manual, "General Wiring Diagram" and "RS-232C Cable Requirements".

Determine the parameters for communication for the installation. The RS-232C default rate of communication (bits per second or bps) is 9600. The remaining default settings from the factory are no parity, 8 data bits, and 1 stop bit. These parameters will work well in most installations. Use the Operation and Maintenance Manual, "Communication Parameters - Identify" to determine the parameters of communication that are stored in the CCM.Note: The RS-232C serial port communication baud rate is often referred to as the DTE speed. The phone port communication rate is often referred to as the DCE speed.

Connect the RS-232C port of the Answering Modem directly to the RS-232C port of the PC. This connection is temporary. This connection is required to set up the Answering Modem.

Use the terminal emulator on the PC to set the parameters for communication for the RS-232C port. Use the same values that were chosen in step 2.

Several commands must be sent to the Answering Modem that set the parameters for communication to the proper values. The examples in Table 1 are Hayes AT commands. Actual command sets vary widely between modem manufacturers. Consult the manual for the modem. Save these parameters to the modem memory.

Table 1

Typical Answering Modem Setup Commands

Item Explanation Command Example Command