Information injection-pump assembly

BOSCH

9 400 615 661

9400615661

ZEXEL

101607-6001

1016076001

MITSUBISHI

ME076911

me076911

Rating:

Service parts 101607-6001 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

14.7(150)/21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 615 661

9400615661

ZEXEL

101607-6001

1016076001

MITSUBISHI

ME076911

me076911

Zexel num

Bosch num

Firm num

Name

101607-6001

9 400 615 661

ME076911 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D16T K

6D16T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.5

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

87

84.4

89.6

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.2

8.7

11.7

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.5)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

87

86

88

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.35

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

96

92

100

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2-0.6

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

57

53

61

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2(R1+0.

25)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

88.5

84.5

92.5

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Rack limit

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

75

115

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

450

450

450

Rack position

R2-0.6

Boost pressure

kPa

6

4.7

7.3

Boost pressure

mmHg

45

35

55

Boost compensator adjustment_02

Pump speed

r/min

450

450

450

Rack position

R2(R1+0.

25)

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

1200--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

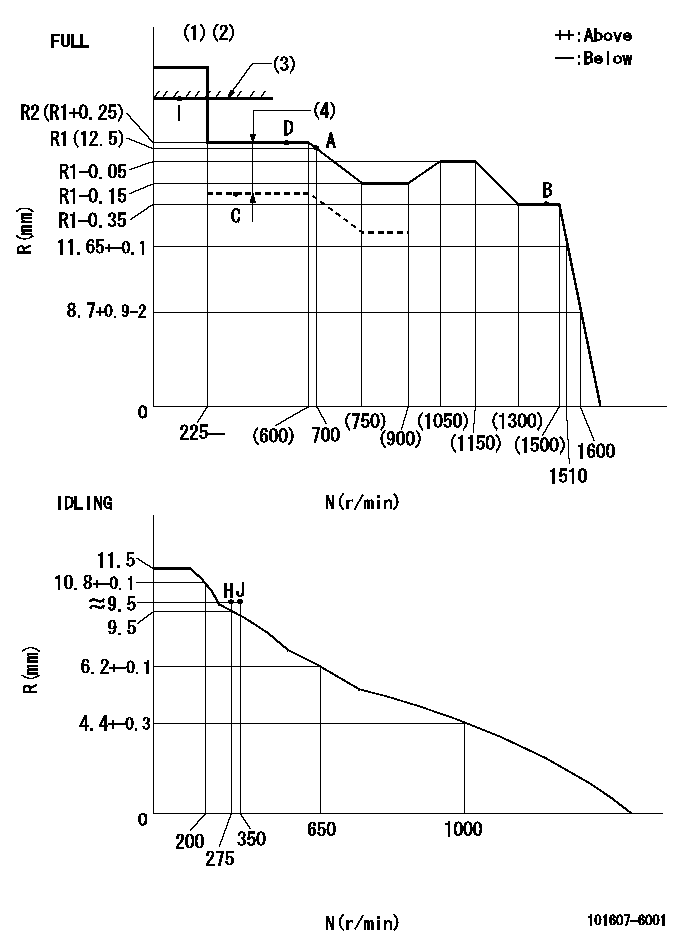

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=D24 BCL=0.6+-0.1mm

----------

----------

T1=D24 BCL=0.6+-0.1mm

----------

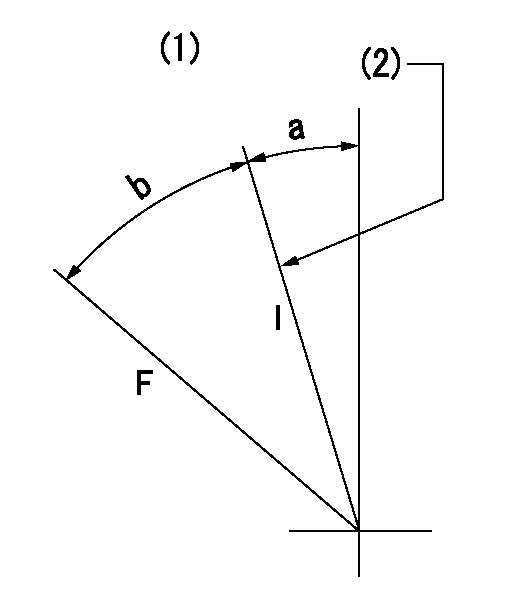

Speed control lever angle

F:Full speed

I:Idle

(1)Accelerator lever

(2)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=41deg+-3deg

----------

----------

a=18.5deg+-5deg b=41deg+-3deg

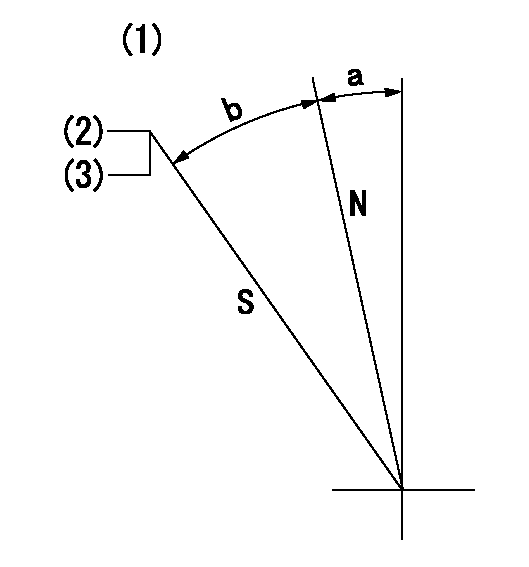

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(3)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

----------

aa=1400r/min bb=6.5-0.5mm cc=275r/min dd=(8.6)-0.5mm

----------

a=11.5deg+-5deg b=27deg+-5deg

----------

aa=1400r/min bb=6.5-0.5mm cc=275r/min dd=(8.6)-0.5mm

----------

a=11.5deg+-5deg b=27deg+-5deg

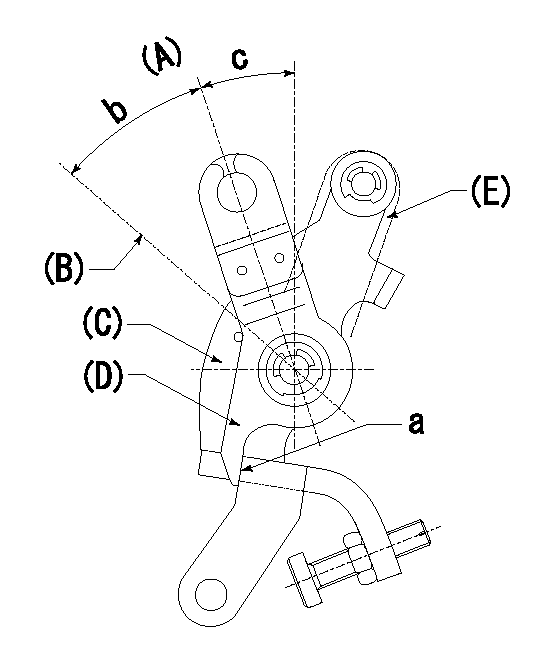

0000001501 LEVER

(A) Idle

(B) Full speed

(C) Base lever

(D) Accelerator lever

(E) Accelerator lever delivery position

1. Measure speed lever angle

(1)Measure the angle when the accelerator lever (D) contacted the base lever (C) at a.

----------

----------

b=41deg+-3deg c=18.5deg+-5deg

----------

----------

b=41deg+-3deg c=18.5deg+-5deg

0000001601 MICROSWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400r/min Ra=9.2+-0.1mm

----------

----------

N1=400r/min Ra=9.2+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

2301A Electric Governor Control

The 2301A Electric Governor Control activates all of the components that are in the electric protection system. The components are activated in the same manner when the nonelectric governor is used. One difference exists in the main circuit. The fuel shutoff solenoid (FSOS) (line 43) is not used.When the electric governor control is used, the engine must run in a normal condition in order for the electric circuit to operate in the manner that is described below.

Current flows from the terminals (TS-28) (line 43) and (TS-31) (line 44), which are located on the terminal strip in the junction box.

Current from terminals (TS-28) (line 43) and (TS-31) (line 44) flows through the preregulator (PR) (line 48) or the fuse (F4) to the electric governor control.

When the engine flywheel is rotating, the current also flows through the electric governor actuator (EGA) (line 52). When a fault in the system causes the current to energize the slave relay (SR1), the following events occur in the electric circuit in order to stop the engine.

The slave relay (SR1) opens across the contacts (SR1-30) and (SR1-87a) (line 45). The relay closes across the contacts (SR1-30) and (SR1-87) (line 43).

When the circuit opens across contacts (SR1-30) and (SR1-87a), the current is stopped to the electric governor control.

Current to the electric governor actuator (EGA) is also stopped.

The mechanical spring load in the electric governor actuator (EGA) will now move the fuel control rod in order to stop fuel flow to the engine. Note: With the exception of the differences that are described in this section of the manual, all of the fault circuits in the electric protection system are identical for the 2301A Electric Governor Control and for the nonelectric governor control.

Illustration 3 g00292636

Junction Box Wiring for ETR protection

Have questions with 101607-6001?

Group cross 101607-6001 ZEXEL

Mitsubishi

101607-6001

9 400 615 661

ME076911

INJECTION-PUMP ASSEMBLY

6D16T

6D16T