Information injection-pump assembly

BOSCH

9 400 612 534

9400612534

ZEXEL

101607-1790

1016071790

Rating:

Service parts 101607-1790 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056371

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 612 534

9400612534

ZEXEL

101607-1790

1016071790

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

112

108.6

115.4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

18.5

15.7

21.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

112

111

113

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9.6)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

113.5

111

116

Difference in delivery

mm3/st.

9

9

9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

120

160

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

0.9

0.4

1.4

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

3

2.5

3.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

4

4

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

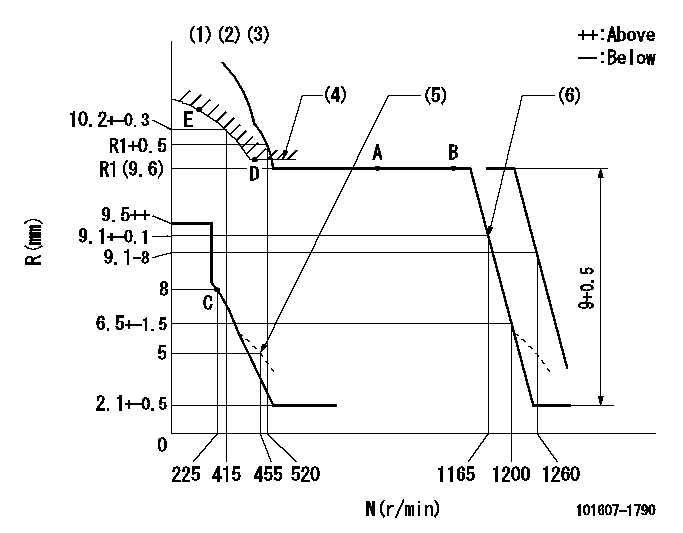

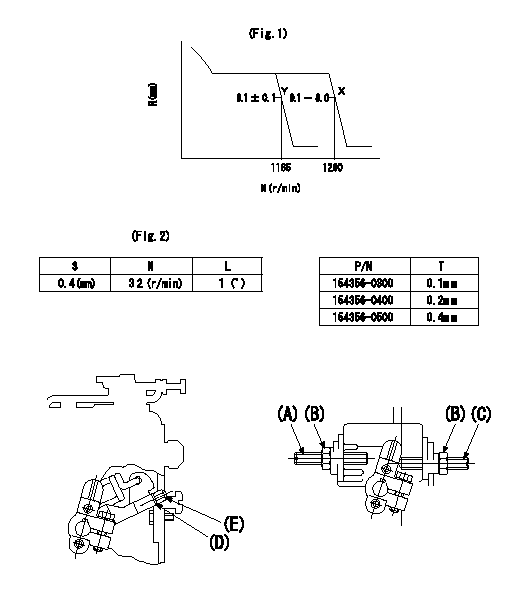

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Excess fuel setting for starting: SXL

(5)Damper spring setting

(6)Set at delivery

----------

RT=1 TH=2.7mm SXL=R1+0.2mm

----------

----------

RT=1 TH=2.7mm SXL=R1+0.2mm

----------

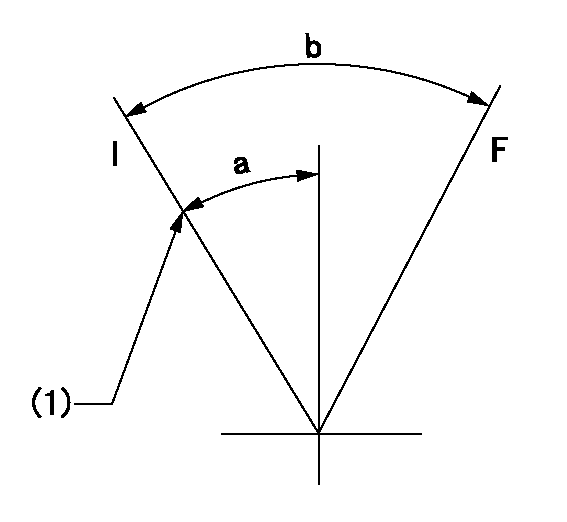

Speed control lever angle

F:Full speed

----------

----------

a=(15deg)+-5deg

----------

----------

a=(15deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24deg+-5deg b=27.5deg+-3deg

----------

----------

a=24deg+-5deg b=27.5deg+-3deg

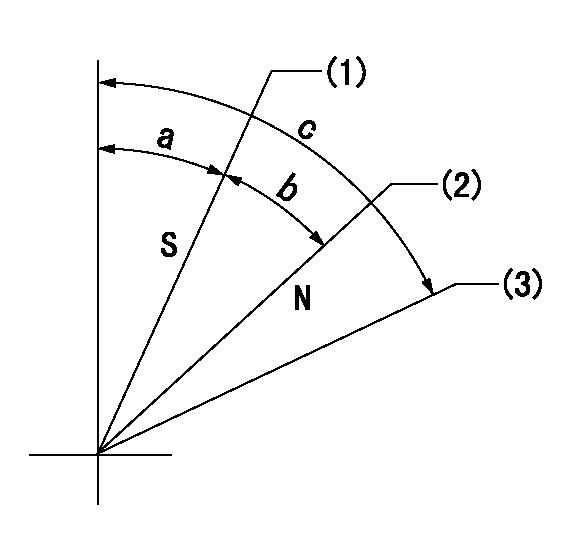

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, stopper bolt setting

(2)Rack position bb

(3)Free (at delivery)

----------

aa=5.5-0.5mm bb=16mm

----------

a=12.5deg+5deg-7deg b=34deg+-5deg c=(66.5deg)

----------

aa=5.5-0.5mm bb=16mm

----------

a=12.5deg+5deg-7deg b=34deg+-5deg c=(66.5deg)

0000001501 TAMPER PROOF

N:Pump speed (r/min)

R:Rack position (mm)

S:Shim thickness (1; mm)

L:Lever angle (deg)

T:Thickness (mm)

P/N: part number of shim

(A) Speed set bolt

Locknut B

Speed set bolt C

(d) Shim

(E) Screw

Tamper proof adjustment

(1)Adjustment standard

1. Tamperproof adjustment specifications are shown in figure 1.

(2)Adjustment procedure

1. Temporarily set with 4 shims (D; thickness = 0.4 mm) assembled.

2. Perform governor adjustment as described in the calibration data sheet.

3. At this time, confirm that the specified setting (point Y: 1165 r/min) can be obtained using the speed set bolt (A).

4-1 When specified setting can be obtained

4-1-1 Back off the speed set bolt (C).

4-1-2 Confirm that point X is satisfied when the speed set bolt (A) is further tightened.

4-2 When specified setting can be obtained

4-2-1 Repeat disassembly and confirm that the specified setting (point Y: 1165 r/min) can be obtained when a suitable number of shims (D) are removed.

4-2-2 As in 4-1 above, confirm that the point X is satisfied when the setting is increased.

4-2-3 Adjust after referring to figure 2 for the number of shims.

Reference: Screw (E) and the pump housing contact in 4-1 and 4-2 above.

5-1 After completing confirmation in (1), reset at the specified setting (point Y: 1165 r/min) using the speed set bolt (A) and (C).

5-2 fix using locknut (B) and finish adjustment.

----------

----------

----------

----------

0000001601 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=7.3+-0.1mm

----------

----------

N1=325r/min Ra=7.3+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Introduction

This Special Instruction contains the strap torquing procedure for the straps on the DEF tank.Read the entire Special Instruction. Understand the information before you perform any procedures. Strap Torquing Procedure

Illustration 1 g03354750

(1) Strap (2) Nut

Install strap (1) and torque nut (2) .Torque for nut (2) ... 11 1 N m (97 9 lb in)Note: If the strap has a hook or other non-adjustable fastener on one end, only the adjustment end is torqued during installation.Note: If both ends of the strap have adjustable fasteners, both ends should be torqued only once. Do not go back and forth when applying assembly torque. Torque the first side to specification, then ensure that the torque on the second side is at specifications. Do not go back and retorque the first side.

This Special Instruction contains the strap torquing procedure for the straps on the DEF tank.Read the entire Special Instruction. Understand the information before you perform any procedures. Strap Torquing Procedure

Illustration 1 g03354750

(1) Strap (2) Nut

Install strap (1) and torque nut (2) .Torque for nut (2) ... 11 1 N m (97 9 lb in)Note: If the strap has a hook or other non-adjustable fastener on one end, only the adjustment end is torqued during installation.Note: If both ends of the strap have adjustable fasteners, both ends should be torqued only once. Do not go back and forth when applying assembly torque. Torque the first side to specification, then ensure that the torque on the second side is at specifications. Do not go back and retorque the first side.