Information injection-pump assembly

BOSCH

F 019 Z10 609

f019z10609

ZEXEL

101607-1650

1016071650

Rating:

Service parts 101607-1650 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME076088

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)/21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 609

f019z10609

ZEXEL

101607-1650

1016071650

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

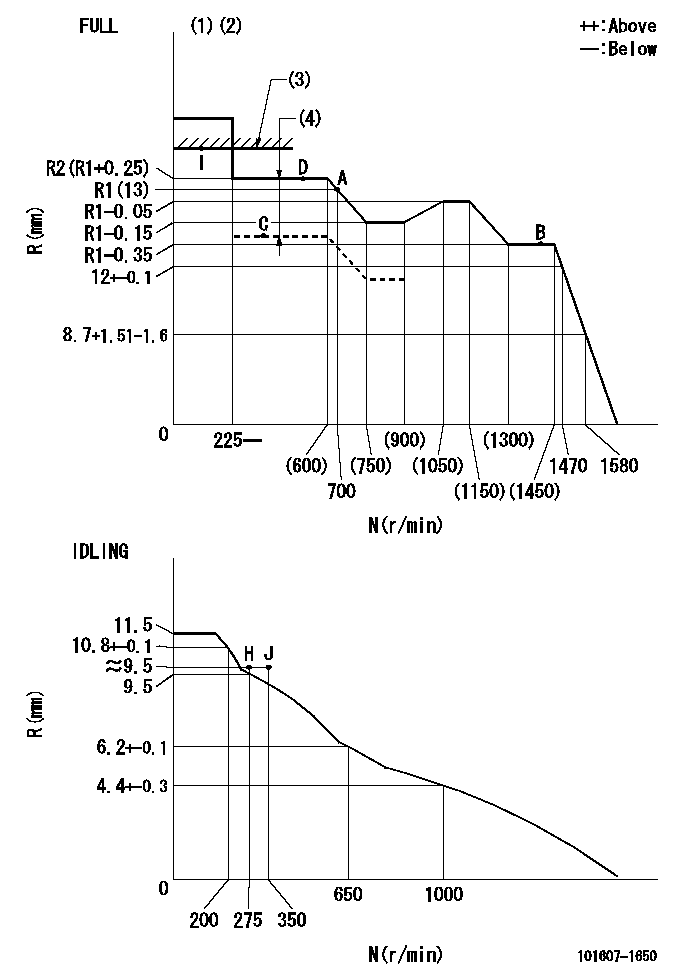

Injection quantity adjustment

Adjusting point

-

Rack position

13

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

96.8

93.9

99.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.2

8.7

11.7

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

96.8

95.8

97.8

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.35

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

100.3

96.3

104.3

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2-0.6

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

66.9

62.9

70.9

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2(R1+0.

25)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

96.5

92.5

100.5

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

75

115

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

450

450

450

Rack position

R2-0.6

Boost pressure

kPa

6

4.7

7.3

Boost pressure

mmHg

45

35

55

Boost compensator adjustment_02

Pump speed

r/min

450

450

450

Rack position

R2(R1+0.

25)

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

1200--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Boost compensator stroke: BCL

----------

T1=D24 BCL=0.6+-0.1mm

----------

----------

T1=D24 BCL=0.6+-0.1mm

----------

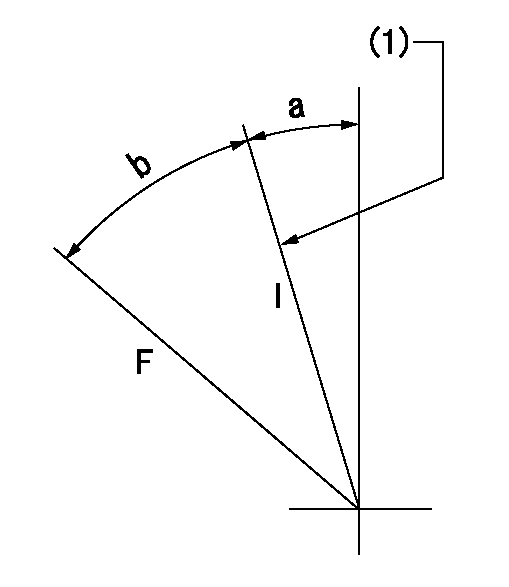

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=20deg+-5deg b=40deg+-3deg

----------

----------

a=20deg+-5deg b=40deg+-3deg

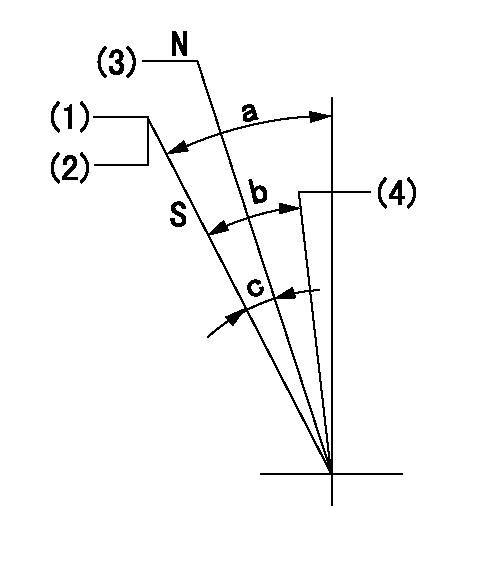

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

(3)Rack position = approximately ee.

(4)Free (at shipping)

----------

aa=1400r/min bb=6.5-0.5mm cc=275r/min dd=(8.6)-0.5mm ee=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

----------

aa=1400r/min bb=6.5-0.5mm cc=275r/min dd=(8.6)-0.5mm ee=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400r/min Ra=9.2+-0.1mm

----------

----------

N1=400r/min Ra=9.2+-0.1mm

----------

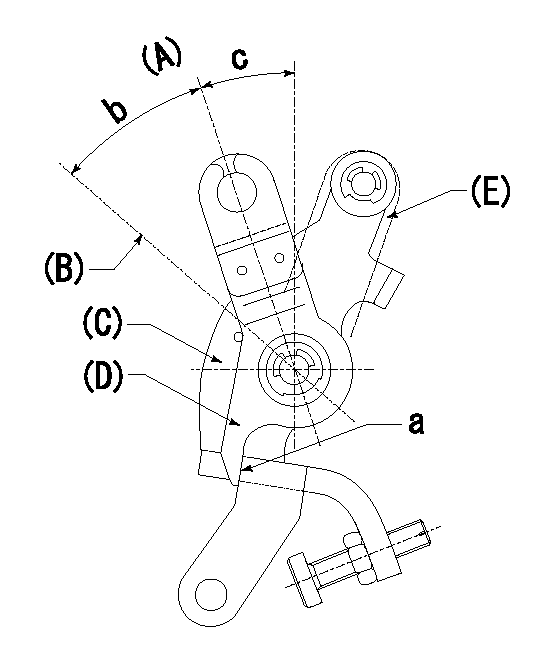

0000001601 LEVER

(A) Idle

(B) Full speed

(C) Base lever

(D) Accelerator lever

(E) Accelerator lever delivery position

1. Measure speed lever angle

(1)Measure the angle when the accelerator lever (D) contacted the base lever (C) at a.

----------

----------

b=40deg+-3deg c=20deg+-5deg

----------

----------

b=40deg+-3deg c=20deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

Introduction

Note: Do not perform any procedure in this Special Instruction until the information has been read and understood.Injector Wiring Harness Kit

The new 141-7060 Injector Wiring Harness Kit is available to repair the connectors on the 122-8835 Wiring Harness Assembly or the 133-3745 Wiring Harness Assembly . The connectors on the wiring harness assembly connect to the Hydraulic Electronic Unit Injectors (HEUI) in the above Caterpillar Truck Engines. Each injector wiring harness kit includes:

one connector

two barrel splices

two pieces of heat shrink tubingInstallation Of The 141-7060 Injector Wiring Harness Kit

Carefully remove the valve cover from the engine. Avoid damaging the gasket on the valve cover.

Remove the damaged connector from the HEUI injector solenoid.

Cut the damaged connector from the HEUI injector wiring harness. A length of 31.8 mm (1.25 inch) should remain from the heat shrink tubing on one of the harness wires. A length of 19.1 mm (0.75 inch) should remain from the heat shrink tubing on the other harness wire.Note: DO NOT allow the removed insulation to fall into the cylinder head assembly. DO NOT allow the removed insulation to fall into the open passages of the oil sump.

Remove approximately 8 mm (0.3 inch) of the insulation from the two harness wires.Note: Remove only enough insulation in order to allow the harness wires to seat into the new barrel splice from the injector wiring harness kit.

Remove the two pieces of the heat shrink tubing from the injector wiring harness kit.

Slip the heat shrink tubing from the injector wiring harness kit over the ends of the HEUI injector wiring harness wires.Note: The heat shrink tubing must be pushed far enough onto the harness wires so that the heat shrink tubing will not be cut when crimping the barrel splices. DO NOT crimp through the heat shrink tubing. Crimping through the heat shrink tubing will cause damage.

Remove the replacement connector from the injector wiring harness kit.

Install the replacement connector on the HEUI injector wiring harness wires.

Crimp the two barrel splices to the HEUI injector wiring harness wires.

Move the heat shrink tubing over the exposed barrel splices. Center the barrel splices in the heat shrink tubing.

Use a heat gun to heat the heat shrink tubing. Apply heat until the tubing shrinks evenly around the barrel splices.Note: DO NOT overheat the heat shrink tubing. Damage to the heat shrink tubing may result. The appearance of the heat shrink tubing should be uniform and smooth when properly shrunk.

Connect the repaired HEUI injector wiring harness connector to the HEUI injector solenoid.

Inspect the valve cover gasket for damage. Replace the valve cover gasket if the gasket is damaged.

Install the valve cover gasket. Install the valve cover.

Start the engine. Test the effectiveness of the repair.

Note: Do not perform any procedure in this Special Instruction until the information has been read and understood.Injector Wiring Harness Kit

The new 141-7060 Injector Wiring Harness Kit is available to repair the connectors on the 122-8835 Wiring Harness Assembly or the 133-3745 Wiring Harness Assembly . The connectors on the wiring harness assembly connect to the Hydraulic Electronic Unit Injectors (HEUI) in the above Caterpillar Truck Engines. Each injector wiring harness kit includes:

one connector

two barrel splices

two pieces of heat shrink tubingInstallation Of The 141-7060 Injector Wiring Harness Kit

Carefully remove the valve cover from the engine. Avoid damaging the gasket on the valve cover.

Remove the damaged connector from the HEUI injector solenoid.

Cut the damaged connector from the HEUI injector wiring harness. A length of 31.8 mm (1.25 inch) should remain from the heat shrink tubing on one of the harness wires. A length of 19.1 mm (0.75 inch) should remain from the heat shrink tubing on the other harness wire.Note: DO NOT allow the removed insulation to fall into the cylinder head assembly. DO NOT allow the removed insulation to fall into the open passages of the oil sump.

Remove approximately 8 mm (0.3 inch) of the insulation from the two harness wires.Note: Remove only enough insulation in order to allow the harness wires to seat into the new barrel splice from the injector wiring harness kit.

Remove the two pieces of the heat shrink tubing from the injector wiring harness kit.

Slip the heat shrink tubing from the injector wiring harness kit over the ends of the HEUI injector wiring harness wires.Note: The heat shrink tubing must be pushed far enough onto the harness wires so that the heat shrink tubing will not be cut when crimping the barrel splices. DO NOT crimp through the heat shrink tubing. Crimping through the heat shrink tubing will cause damage.

Remove the replacement connector from the injector wiring harness kit.

Install the replacement connector on the HEUI injector wiring harness wires.

Crimp the two barrel splices to the HEUI injector wiring harness wires.

Move the heat shrink tubing over the exposed barrel splices. Center the barrel splices in the heat shrink tubing.

Use a heat gun to heat the heat shrink tubing. Apply heat until the tubing shrinks evenly around the barrel splices.Note: DO NOT overheat the heat shrink tubing. Damage to the heat shrink tubing may result. The appearance of the heat shrink tubing should be uniform and smooth when properly shrunk.

Connect the repaired HEUI injector wiring harness connector to the HEUI injector solenoid.

Inspect the valve cover gasket for damage. Replace the valve cover gasket if the gasket is damaged.

Install the valve cover gasket. Install the valve cover.

Start the engine. Test the effectiveness of the repair.