Information injection-pump assembly

BOSCH

F 019 Z10 836

f019z10836

ZEXEL

101607-1560

1016071560

Rating:

Service parts 101607-1560 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME086575

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)

15.

NOZZLE SET

Include in #1:

101607-1560

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-6620

as _

Cross reference number

BOSCH

F 019 Z10 836

f019z10836

ZEXEL

101607-1560

1016071560

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-6720

Overflow valve opening pressure

kPa

191

157

225

Overflow valve opening pressure

kgf/cm2

1.95

1.6

2.3

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.3

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

41.1

39.5

42.7

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8.3

7

9.6

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

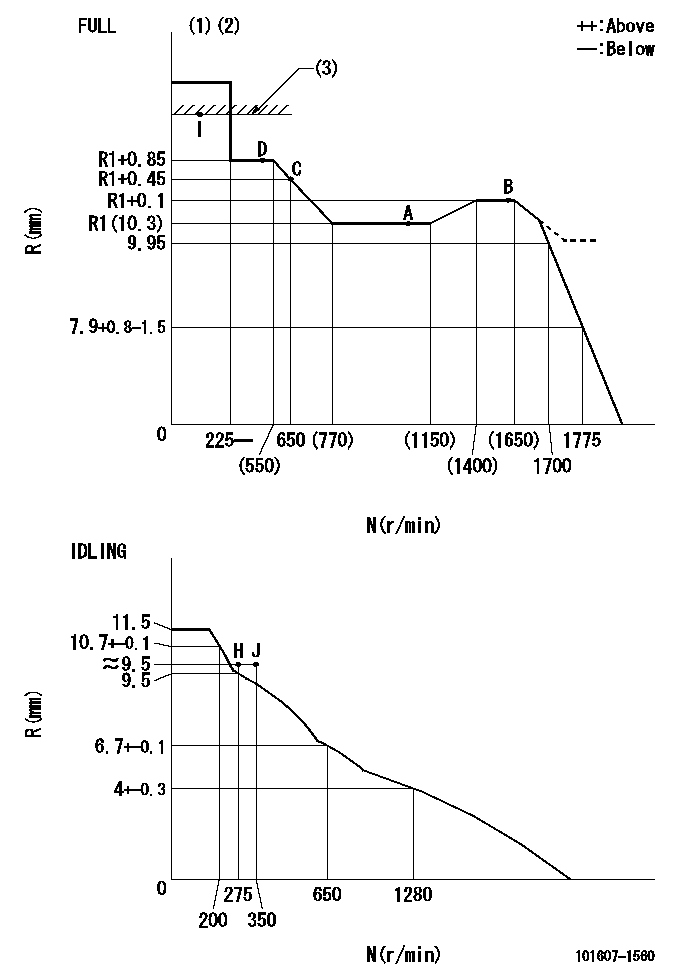

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.3)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

41.1

40.1

42.1

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.1

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

46.6

42.6

50.6

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.45

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

41

37

45

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R1+0.85

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

36.1

32.1

40.1

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

63

63

68

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1150--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=F66

----------

----------

T1=F66

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=40mm

----------

a=26deg+-5deg b=37deg+-3deg

----------

aa=40mm

----------

a=26deg+-5deg b=37deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Free (at shipping)

(2)Use the hole at R = aa

(3)Rack position corresponding to bb

(4)Set the stopper bolt so that speed = cc and rack position = dd.

(5)After setting the stopper bolt, confirm non-injection at speed ee. (Rack position = ff or less)

----------

aa=40mm bb=16mm cc=1700r/min dd=6.5-0.5mm ee=275r/min ff=8mm

----------

a=8deg+-5deg b=15deg+-5deg c=25deg+-5deg

----------

aa=40mm bb=16mm cc=1700r/min dd=6.5-0.5mm ee=275r/min ff=8mm

----------

a=8deg+-5deg b=15deg+-5deg c=25deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(2deg)

----------

aa=12deg

----------

a=(2deg)

Information:

TECHNICAL INFORMATION BULLETIN November 30, 2005

This Technical Information Bulletin replaces the November 11, 2005 TIB "System Malfunctions Related To The Injection Actuation Pressure Sensors In Excavators, Wheel Loaders, Engines, Track-Type Tractors and Track Loaders". Disregard the November 11, 2005 TIB. Refer to the following information.

Excavators 322C (EMR215-523,MAR165-468)

325C (CRB650-1677,CSJ800-1486)

(DTF276-285,JLC283-306)

(JLD313-348)

330C (CAP950-2085,CGZ444-889)

(JCD285-351,MKM308-316)

330CL(JNK238-343)

Wheel Loaders 938GII (PHN550-2023)

950GII (AYB693-1086)

(AYL1039-2384)

962GII (AYE530-695,BAB437-758)

Engines C9 (C9B1-266,CSN1-1070)

(JLW1-279,JSC1-395)

(MTB1-1550,X9X1-258)

Track-Type Tractors D6N LGP (ALR1-715)

(ALY1-1932)

(CCG1-261)

(CCS1-402)

D6N XL (AKM1-1694,ALH1-794)

(CBF1-309,CBJ1-448)

(CBL1-400,CCK1-623)

D6RII (AEM1-117,BPM1-104)

(BRJ1-201,CAD1-257)

(FDT1-362)

D6RII LGP (ACJ1-113)

(ADE1-1016)

(AFD1-98)

(BNC1-433)

(BPP1-502)

(BPZ1-532)

D6RII XL (AAX1-139)

(AGM1-111)

(BMJ1-166)

(BMY1-479)

(BPS1-503)

(BRZ1-537)

D6RII XW (AEP1-711)

(BRE1-501)

(DAE1-192)

D6RIII LGP (WCB1-111,WRG1-157)

D6RIII XW (HDC1-132,MRT1-1)

Track Loader 963C (BBD1-2311)

Component Code 1925SUBJECT: System Malfunctions Related To The Injection Actuation Pressure Sensors In Excavators, Wheel Loaders, Engines, Track-Type Tractors and Track Loaders

PROBLEM:

The Injection Actuation Pressure (IAP) sensors are being replaced on machine applications with C7/3126 engines. Some C9 engine models are also affected. The system event code 164-11 or 164-02 leads the technician to replace the sensor. Many of these sensors are no fault found. The result of these failures is loss of production due to unscheduled downtime.

SOLUTION:

Follow current troubleshooting guidelines for highway trucks to troubleshoot the part causing the failure. This will aid the technician in finding the correct part causing the failure. Report any troubleshooting guidelines errors using the feedback function in the Service Information System (SIS Web).

COPYRIGHT 2005 CATERPILLAR

ALL RIGHTS RESERVED