Information injection-pump assembly

BOSCH

F 01G 09U 05A

f01g09u05a

ZEXEL

101607-1420

1016071420

MITSUBISHI

ME076682

me076682

Rating:

Include in #1:

101401-7560

as _

Cross reference number

BOSCH

F 01G 09U 05A

f01g09u05a

ZEXEL

101607-1420

1016071420

MITSUBISHI

ME076682

me076682

Zexel num

Bosch num

Firm num

Name

101607-1420

F 01G 09U 05A

ME076682 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D14 * K

6D14 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.6

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

61

59.2

62.8

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

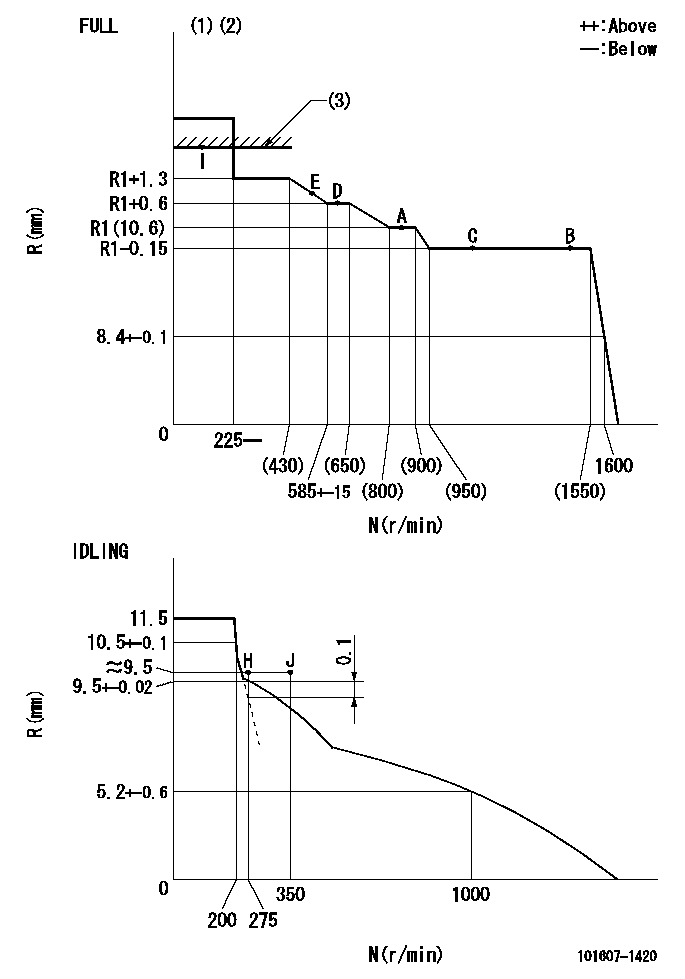

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.5

9

12

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.6)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

61

60

62

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

R1+0.6

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

62

58

66

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

14.1+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

70

110

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

0.8

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

2.6

2.1

3.1

Timer adjustment_05

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=D89

----------

----------

T1=D89

----------

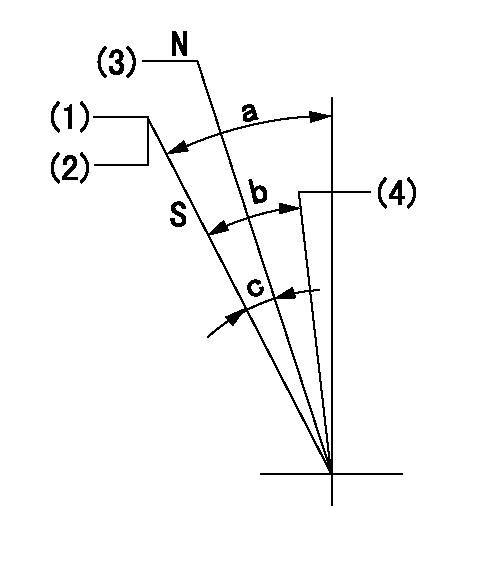

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=24deg+-5deg b=42deg+-3deg

----------

----------

a=24deg+-5deg b=42deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

(3)Rack position = approximately ee.

(4)Free (at shipping)

----------

aa=1550r/min bb=7.2-0.5mm cc=275r/min dd=8.2mm ee=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

----------

aa=1550r/min bb=7.2-0.5mm cc=275r/min dd=8.2mm ee=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

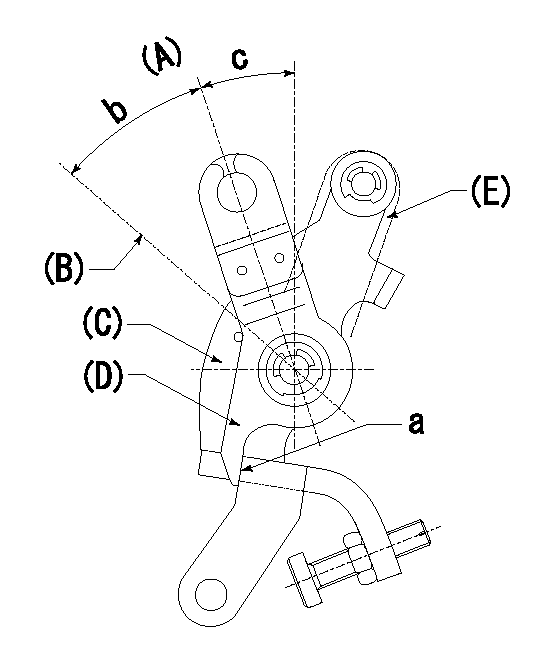

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400r/min Ra=9.2+-0.1mm

----------

----------

N1=400r/min Ra=9.2+-0.1mm

----------

0000001601 LEVER

(A) Idle

(B) Full speed

(C) Base lever

(D) Accelerator lever

(E) Accelerator lever delivery position

1. Measure speed lever angle

(1)Measure the angle when the accelerator lever (D) contacted the base lever (C) at a.

----------

----------

b=42deg+-3deg c=24deg+-5deg

----------

----------

b=42deg+-3deg c=24deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(1deg)

----------

aa=16deg

----------

a=(1deg)

Information:

*******Group 16*******

100% 100% 0% 0% 0% 0%

This is a 5.0-hour job for Group 16

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 17*******

100% 100% 0% 0% 0% 0%

This is a 7.0-hour job for Group 17

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 18*******

100% 100% 0% 0% 0% 0%

This is a 8.0-hour job for Group 18

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 19*******

100% 100% 0% 0% 0% 0%

This is a 1.0-hour job for Group 19

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

EXAMPLE COPY OF OWNER NOTIFICATION

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR REPLACING FUEL INJECTORS

MODELS INVOLVED - CERTAIN 3508C, 3512B, 3512C, 3516C, AND 3516E GENERATOR SETS, MARINE ENGINES, AND PETROLEUM ENGINES

Dear Cat Product Owner:

Certain fuel injectors need to be replaced on the products listed below. The existing fuel injectors can cause the cylinder to be over fueled and possibly lead to engine damage. You will not be charged for the service performed.

Contact your local Cat dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

If you are no longer the owner of this product(s), please contact your local Cat dealer so that our records can be updated. Please refer the dealer to their Service Letter dated 19Mar2018 when scheduling this service.

We regret the inconvenience this may cause you, and urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 19Mar2018 Service Letter

Have questions with 101607-1420?

Group cross 101607-1420 ZEXEL

Mitsubishi

101607-1420

F 01G 09U 05A

ME076682

INJECTION-PUMP ASSEMBLY

6D14

6D14