Information injection-pump assembly

BOSCH

F 01G 09U 059

f01g09u059

ZEXEL

101607-1350

1016071350

MITSUBISHI

ME076685

me076685

Rating:

Include in #1:

101401-7490

as _

Cross reference number

BOSCH

F 01G 09U 059

f01g09u059

ZEXEL

101607-1350

1016071350

MITSUBISHI

ME076685

me076685

Zexel num

Bosch num

Firm num

Name

101607-1350

F 01G 09U 059

ME076685 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D16 * K

6D16 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

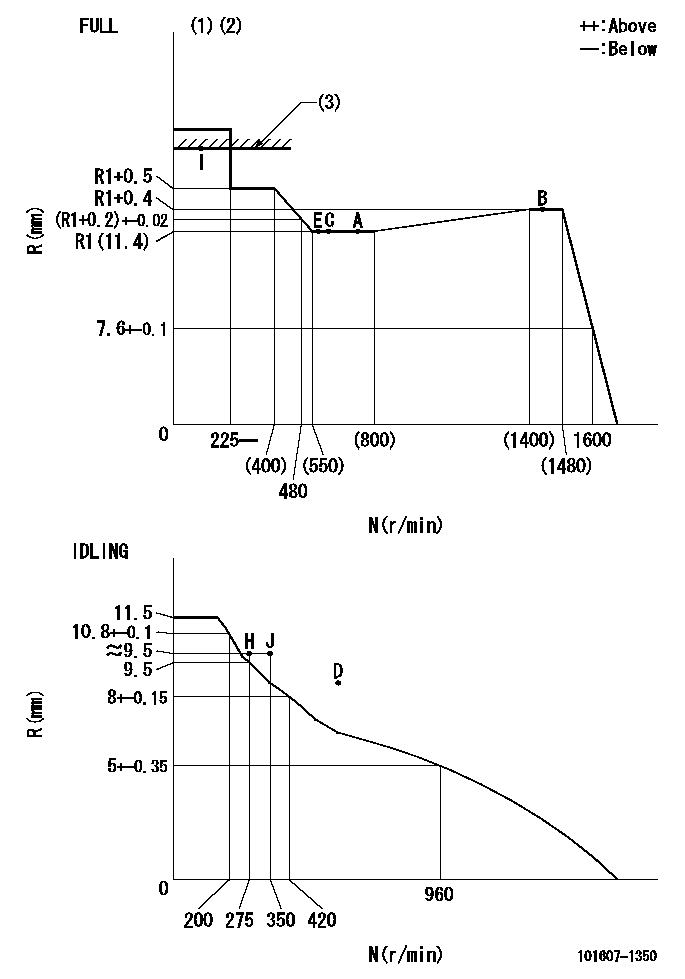

Injection quantity adjustment

Adjusting point

-

Rack position

11.4

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

54.5

52.9

56.1

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

D

Rack position

8.7+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

7.6

6.5

8.7

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

54.5

53.5

55.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.4

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

79.8

75.8

83.8

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1(11.4)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

48.5

44.5

52.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

14.3+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

73

63

83

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_07

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

8.7

7.4

10

Fixing the rack

*

Remarks

(check)

(check)

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1200

Advance angle

deg.

2.7

2.2

3.2

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=D53

----------

----------

T1=D53

----------

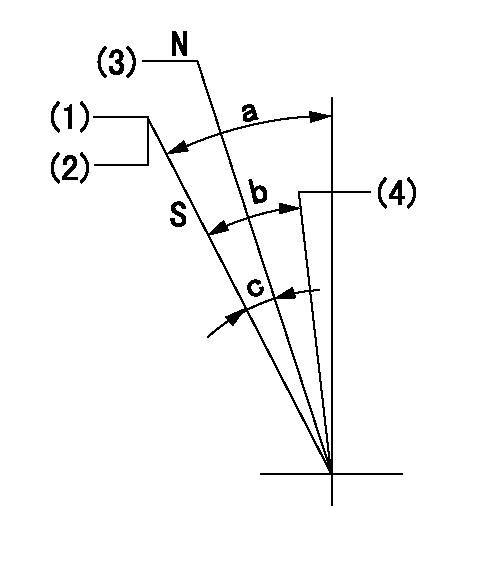

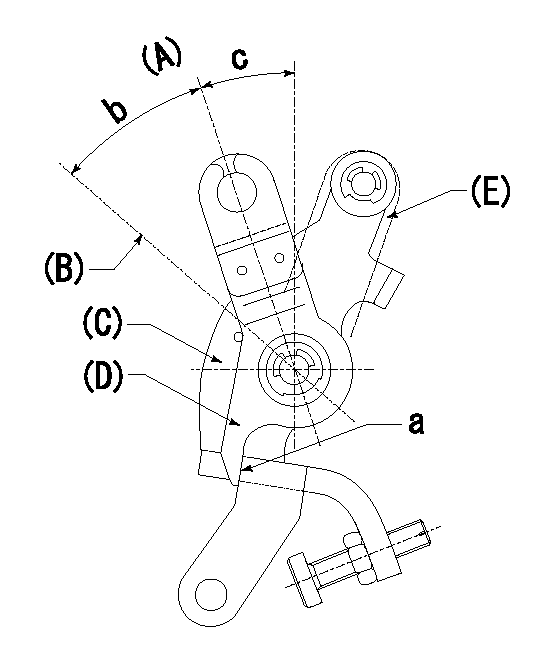

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=41deg+-3deg

----------

----------

a=18.5deg+-5deg b=41deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)At the rated pump speed and rack position aa, set the stopper bolt. Confirm non-injection. Rack position = bb (non-injection rack position)

(2)After setting the stopper bolt, confirm non-injection at speed = cc.

(3)Rack position = approximately dd

(4)Free (at shipping)

----------

aa=6.7-0.5mm bb=(8.3)mm cc=275r/min dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

----------

aa=6.7-0.5mm bb=(8.3)mm cc=275r/min dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

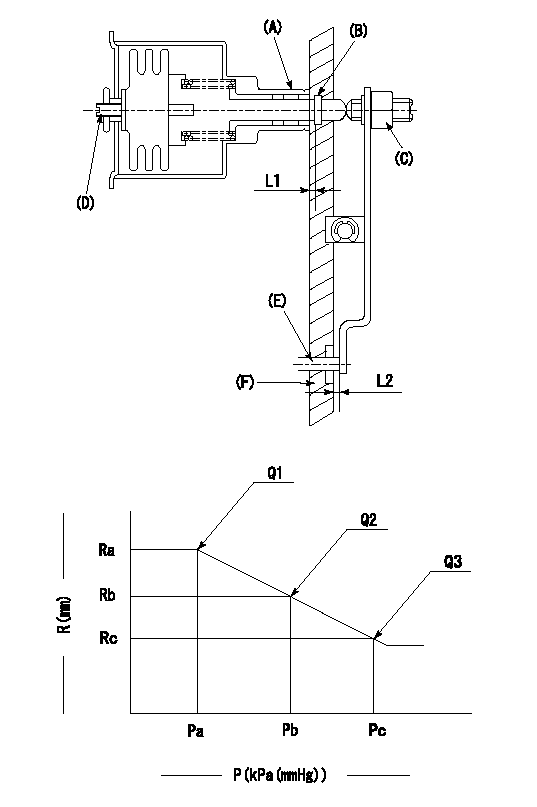

0000001501 ACS

(A) Housing

(B) Snap ring

(C) adjusting screw

(D) Set screw

(E): Push rod

(F) Spacer

1. Adjustment of the aneroid compensator

(1)Adjust with the (D) set screw so that the clearance between the (A) housing and (B) snap ring is L1.

(2)Select the push rod (E) so that the distance from the end surface of the (F) spacer becomes L2.

(3)Turn adjusting screw (C) to adjust the start of aneroid compensator operation.

2. Adjustment when mounting the governor.

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Turn adjusting screw (C) to obtain the performance shown in the graph above.

(3)After final adjustment, confirm that the gap between housing (A) and snapring (B) is L3.

----------

N1=1450r/min L1=1.4~1.7mm L2=0.5+-0.5mm L3=(0.1~0.5)mm

----------

Ra=R1+0.4mm Rb=R1-0.2+-0.2mm Rc=R1-0.8+-0.1mm Pa=94.6+4kPa(710+30mmHg) Pb=79.4kPa(596mmHg) Pc=61.6kPa(462mmHg) Q1=(79.8)+-2cm3/1000st Q2=- Q3=(52)+-2cm3/1000st

----------

N1=1450r/min L1=1.4~1.7mm L2=0.5+-0.5mm L3=(0.1~0.5)mm

----------

Ra=R1+0.4mm Rb=R1-0.2+-0.2mm Rc=R1-0.8+-0.1mm Pa=94.6+4kPa(710+30mmHg) Pb=79.4kPa(596mmHg) Pc=61.6kPa(462mmHg) Q1=(79.8)+-2cm3/1000st Q2=- Q3=(52)+-2cm3/1000st

0000001601 LEVER

(A) Idle

(B) Full speed

(C) Base lever

(D) Accelerator lever

(E) Accelerator lever delivery position

1. Measure speed lever angle

(1)Measure the angle when the accelerator lever (D) contacted the base lever (C) at a.

----------

----------

b=41deg+-3deg c=18.5deg+-5deg

----------

----------

b=41deg+-3deg c=18.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(1deg)

----------

aa=16deg

----------

a=(1deg)

Information:

03May2017

U-247

A-163

D-194

O-200

TM-3

Parts stock action only

PRODUCT IMPROVEMENT PROGRAM FOR INSPECTING AND POSSIBLY REWORKING CERTAIN REMAN FUEL INJECTORS IN DEALER PARTS STOCK

7750 PI70664

Caterpillar’s obligations under this Service Letter are subject to, and shall not apply in contravention of, the laws, rules, regulations, directives, ordinances, orders, or statutes of the United States, or of any other applicable jurisdiction, without recourse or liability with respect to Caterpillar.

When submitting claim for Parts Stock Action, Use the appropriate 99Z as the s/n, the appropriate Service Letter Program Number as the Part number in the Part Causing Failure field, "7751" as the Group Number, "56" as the Description Code.

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

TERMINATION DATE

31Aug2017

PROBLEM

Certain Reman fuel injectors were labeled with the same "2755" trim code from January 9, 2017 through April 18, 2017. The injector serial numbers of suspect injectors are 1825569 through 1880788. The trim code may or may not be correct. Image 1 shows a suspect trim code.

Parts from part distribution centers have been inspected and the boxes have been marked with a large green dot to indicate the injector has been inspected, marked correctly, or the trim code is correct. Refer to Image 2.

ACTION REQUIRED

Inspect the following Reman injectors in dealer parts stock:

20R0848

20R0849

20R0850

20R0863

20R0864

20R1264

20R1265

20R1266

20R1268

20R1269

20R1270

20R1271

20R1272

20R1273

20R1274

20R1275

20R1276

20R1277

20R1278

20R1279

20R1280

20R1281

20R1282

20R1283

20R2296

20R3247

20R3477

20R3479

20R3480

20R3483

Inspect the date code on the box.

If the date code on the box is not January 9, 2017 through April 18, 2017, then mark the box as inspected per this program and place the part back in dealer parts stock.

If the date code on the box is January 9, 2017 through April 18, 2017, then inspect the injector trim code.

If the trim code is not "2755", then mark the box as inspected per this program and place the part back in dealer parts stock.

If the trim code is "2755", then inspect the injector serial number using the following inspection and rework the procedure:

Use the following web address and download the spreadsheet file:

https://cat.box.com/s/4fwh9nz0lwguh8vomifxj2rapqjc27e9

Use the downloaded file. Type in the injector serial number to check the trim code. The spreadsheet will return whether the trim code is OK to use, or rework and mark the injector with the correct trim code.

Note: Some injector serial numbers will show "2755" as the correct trim code.

If the trim code is correct (acceptable trim code), record the injector serial number, then mark the box as inspected per this program and place the part back in dealer parts stock.

If the trim code is not correct (rework), the injector must be relabeled. Use an engraving tool to cross out the original trim code and write the correct trim code as shown in Image 3. Record the injector serial number and the updated/corrected trim code, then mark the box as reworked per this program and place the part back in dealer parts stock.

Image1

Image2

Image3

SERVICE CLAIM ALLOWANCES

Submit one claim for all parts inspected and reworked from dealer parts stock.

Have questions with 101607-1350?

Group cross 101607-1350 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

101607-1350

F 01G 09U 059

ME076685

INJECTION-PUMP ASSEMBLY

6D16

6D16