Information injection-pump assembly

ZEXEL

101606-9961

1016069961

NISSAN-DIESEL

16713Z6373

16713z6373

Rating:

Service parts 101606-9961 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5665

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

101606-9961

as INJECTION-PUMP ASSEMBLY

Include in #2:

104134-1071

as _

Cross reference number

ZEXEL

101606-9961

1016069961

NISSAN-DIESEL

16713Z6373

16713z6373

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

134424-1520

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.4

3.35

3.45

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

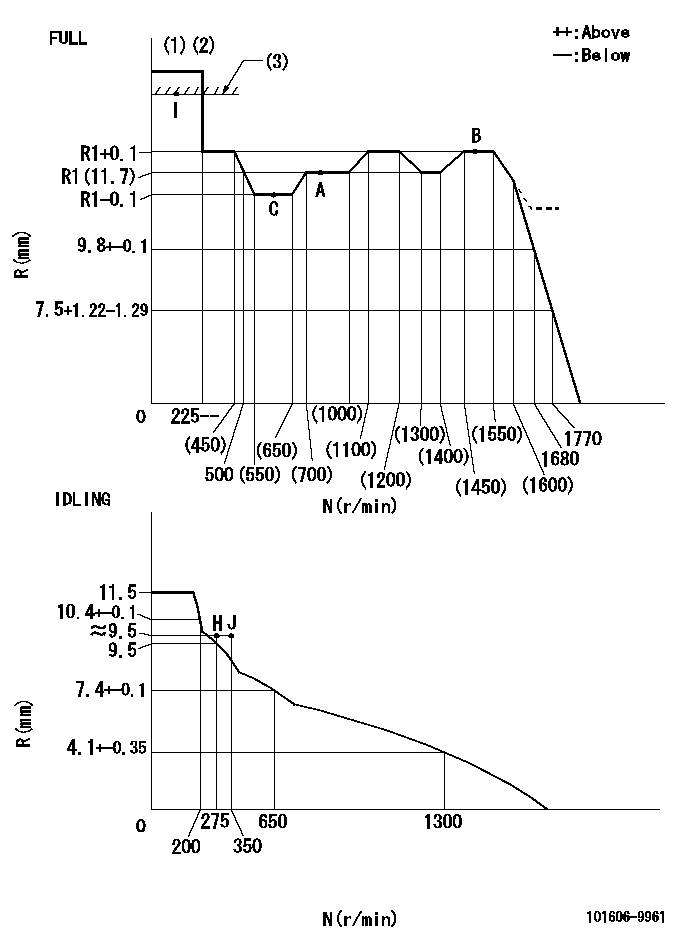

Injection quantity adjustment

Adjusting point

-

Rack position

11.7

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

71

69.4

72.6

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

10.5

8.7

12.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.7)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

71

70

72

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.1

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

84

80

88

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

82

82

92

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1200--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1500

Advance angle

deg.

6.5

6.2

6.8

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=J50

----------

----------

T1=J50

----------

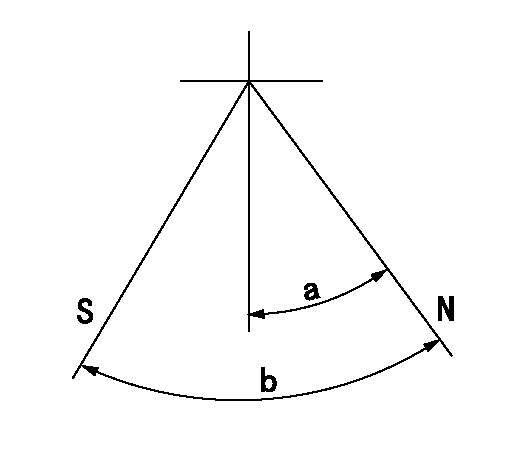

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=36mm

----------

a=20.5deg+-5deg b=36deg+-3deg

----------

aa=36mm

----------

a=20.5deg+-5deg b=36deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=40deg+-5deg

----------

----------

a=20deg+-5deg b=40deg+-5deg

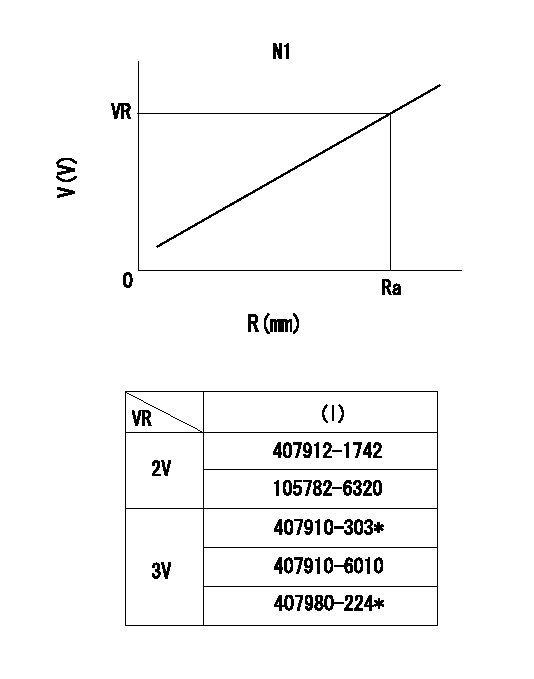

0000001501 RACK SENSOR

R:Rack position (mm)

V:Voltage (V)

After installing the rack sensor, confirm the output value (VR).

----------

N1=800r/min Ra=R1(11.7)mm VR=2.5+-0.01V

----------

----------

N1=800r/min Ra=R1(11.7)mm VR=2.5+-0.01V

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Troubleshooting can be difficult. The Troublsehooting Index gives a list of possible problems. To make a repair to a problem, make reference to the cause and correction on the pages that follow.This list of problems, causes, and corrections will only give an indication of where a possible problem can be, and what repairs are needed. Normally, more or other repair work is needed beyond the recommendations in the list.Remember that a problem is not normally caused only by one part, but by the relation of one part with other parts. This list is only a guide and cannot give all possible problems and corrections. The serviceman must find the problem and its source, then make the necessary repairs. For each problem, a list of possible causes and corrections is given. The list of probable causes and corrections should be performed in numeric sequence.1. Engine Crankshaft Will Not Turn When Ignition Switch Is On2. Engine Hard To Or Will Not Start Engine Crankshaft Turns Too Slowly3. Engine Hard To Or Will Not Start Engine Crankshaft Turns Freely4. Engine Misfiring Or Running Rough5. Engine Stall At Low RPM6. Knock Or Miss At Idle7. Rough Idle8. Low Power9. Engine Speed Is Not Stable10. Engine Overspeeds On Start11. Too Much Vibration12. Loud Combustion Noise13. Valve Train Noise14. Oil In Cooling System15. Mechanical Noise (Knock) In Engine16. Fuel Consumption Too High17. Too Much Valve Lash18. Little Or No Valve Lash19. Oil At The Exhaust20. Engine Has Excessive Early Wear21. Coolant In Lubrication Oil22. Too Much Exhaust Smoke (Black Or Gray)23. Too Much Exhaust Smoke (White Or Blue)24. Engine Has Low Oil Pressure25. Engine Uses Too Much Lubrication Oil26. Above Normal Coolant Temperature27. Below Normal Coolant Temperature28. Exhaust Temperature Too High29. Starter Motor Does Not Turn30. Alternator Gives No Charge31. Alternator Charge Rate Is Low Or Not Regular32. Alternator Charge Too High33. Alternator Has Noise34. Fuel In Lubrication Oil35. Fuel In Coolant36. Loss Of Coolant37. Air Inlet Heater38. Soot In The Inlet Manifold39. Air In Fuel