Information injection-pump assembly

BOSCH

F 019 Z10 996

f019z10996

ZEXEL

101606-9791

1016069791

Rating:

Include in #1:

101401-7453

as _

Cross reference number

BOSCH

F 019 Z10 996

f019z10996

ZEXEL

101606-9791

1016069791

Zexel num

Bosch num

Firm num

Name

101606-9791

F 019 Z10 996

DPICO

INJECTION-PUMP ASSEMBLY

6D22 Q

6D22 Q

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

112

109.2

114.8

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.8+-0.5

Pump speed

r/min

450

450

450

Each cylinder's injection qty

mm3/st.

20

17

23

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

112

111

113

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

85

165

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Injection quantity adjustment_05

Adjusting point

F

Rack position

7.3+-0.5

Pump speed

r/min

335

335

335

Average injection quantity

mm3/st.

16

14.5

17.5

Fixing the rack

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

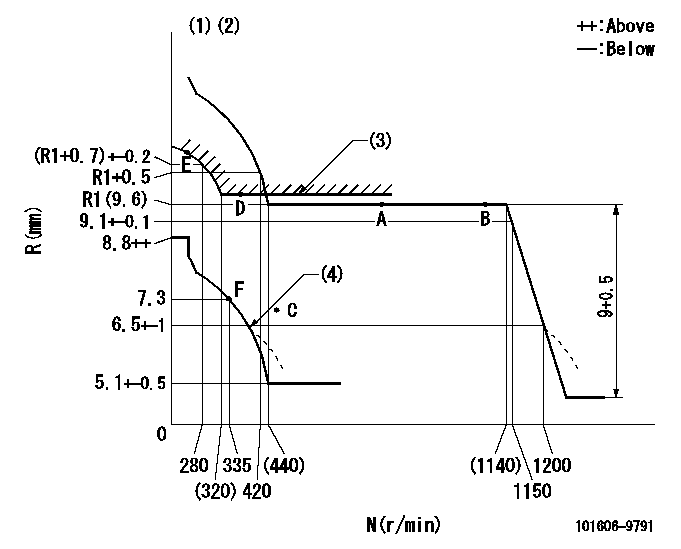

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Microswitch not operating at delivery.

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Excess fuel setting for starting: SXL (N = N1)

(4)Damper spring setting: DL

----------

SXL=(R1+0.1)+0.2mm N1=350r/min DL=6-0.2mm

----------

----------

SXL=(R1+0.1)+0.2mm N1=350r/min DL=6-0.2mm

----------

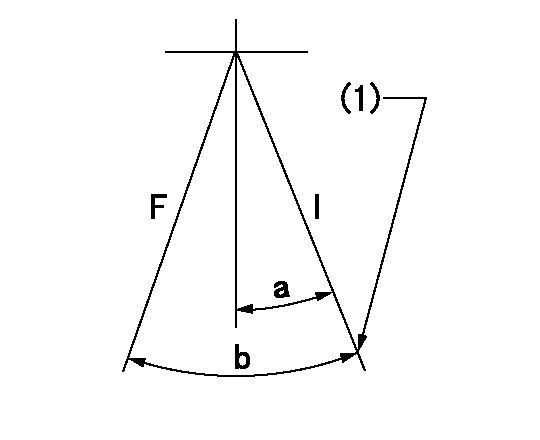

Speed control lever angle

F:Full speed

----------

----------

a=(0.5deg)+-5deg

----------

----------

a=(0.5deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=7.5deg+-5deg b=16.5deg+-3deg

----------

----------

a=7.5deg+-5deg b=16.5deg+-3deg

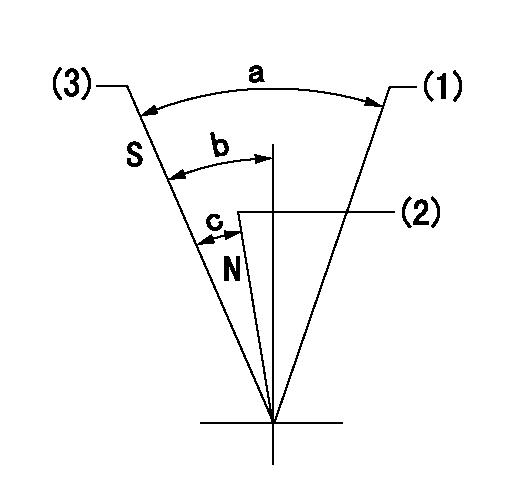

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Free (at delivery)

(2)Rack position = aa

(3)Rack position = bb, set the stopper bolt.

----------

aa=13.5mm bb=6-0.5mm

----------

a=(52deg) b=30deg+-5deg c=24deg+-5deg

----------

aa=13.5mm bb=6-0.5mm

----------

a=(52deg) b=30deg+-5deg c=24deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=15deg

----------

a=(7deg)

----------

aa=15deg

----------

a=(7deg)

Information:

Right Side (6 Cylinder Shown)(1) Depth that cup plugs are installed (measured from block face to top edge of plug) ... 1.25 0.25 mm (.049 .010 in)(2) Distance all sleeves extend from top face ... 14 2 mm (.55 .08 in)(3) Distance two large dowels extend from rear face ... 12.0 0.5 mm (.47 .02 in)(4) Distance two small dowels extend from rear face ... 8.0 0.5 mm (.31 .02 in)(5) Distance all dowels extend from front face ... 8.0 0.5 mm (.31 .02 in)

View A-A (Rear Face)(6) Bores in block for all camshaft bearings except front bearing ... 69.000 0.038 mm (2.7165 .0015 in)(7) Locate bearing oil hole for all camshaft bearings (except front bearing) at top of bore.

Front Face(8) Bore in block for front camshaft bearing ... 70.000 0.025 mm (2.7559 .0010 in)(9) Front camshaft bearing joint location.(10) Front camshaft bearing oil hole. Install front camshaft bearing with bearing oil hole (10) aligned with oil hole in block and bearing joint (9) positioned as shown.(11) Width of main bearing cap ... 159.995 0.020 mm (6.2990 .0008 in) Width of cylinder block for main bearing cap ... 160.000 0.018 mm (6.2992 .0007 in)(12) Bore in block for main bearings ... 95.000 0.013 mm (3.7402 .0005 in)(13) Main bearing cap bolts. Install as follows: Install bearing caps with sequence number to the right, 1 through 5 (for 4 cylinder) or 1 through 7 (for 6 cylinder), front to rear.a. Before assembly, put 2P2506 Thread Lubricant on the bolt threads and washer face.b. Tighten both bolts of each bearing cap to a torque of ... 54 7 N m (40 5 lb ft)c. Then tighten bolts an additional ... 90 5 degrees (1/4 turn)(14) Location of bearing cap sequence number.(15) Dimension from centerline of crankshaft bore to pan rail ... 110.00 mm (4.331 in)(16) Dimension from centerline of crankshaft bore to top of block ... 322.00 .017 mm (12.677 .0007 in)(17) Cylinder bore size ... 105.025 .025 mm (4.1348 .0010 in) Bore size must be checked with a 4C4377 Cylinder Head Stress Plate and gasket installed. Refer to Installation Of 7C6208 Cylinder Sleeve, Special Instruction Form No. SEHS9047. (18) Piston cooling jet. Check piston cooling jets by inserting a 1.3 mm (.05 in) diameter drill rod into jet. Rod must pass through a 5.0 mm (.20 in) diameter circle in location (A) and a 13 mm (.51 in) diameter circle in location (B). Dimension (C) is 25.9 mm (1.02 in). Dimension (D) is 33.4 mm (1.31 in). Dimension (E) is 26.95 mm (1.061 in). Dimension (F) is 9.8 mm (.39 in). Dimension (G) is 50 mm (2.0 in). Distance four sleeves (19) extend from side face ... 5.0 0.5 mm (.20 .02 in)

Have questions with 101606-9791?

Group cross 101606-9791 ZEXEL

Nissan-Diesel

Dpico

101606-9791

F 019 Z10 996

INJECTION-PUMP ASSEMBLY

6D22

6D22