Information injection-pump assembly

BOSCH

9 400 615 556

9400615556

ZEXEL

101606-9200

1016069200

NISSAN-DIESEL

16713Z6064

16713z6064

Rating:

Service parts 101606-9200 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-Z5600

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 615 556

9400615556

ZEXEL

101606-9200

1016069200

NISSAN-DIESEL

16713Z6064

16713z6064

Zexel num

Bosch num

Firm num

Name

101606-9200

9 400 615 556

16713Z6064 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FE6A K 14BE INJECTION PUMP ASSY PE6A PE

FE6A K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-1520

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.2

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

61.6

60

63.2

Max. variation between cylinders

%

0

-3.5

3.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8.7

6.9

10.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.2)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

61.6

60.6

62.6

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.2

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

76.1

72.1

80.1

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

81

81

91

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

(1140)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1500

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

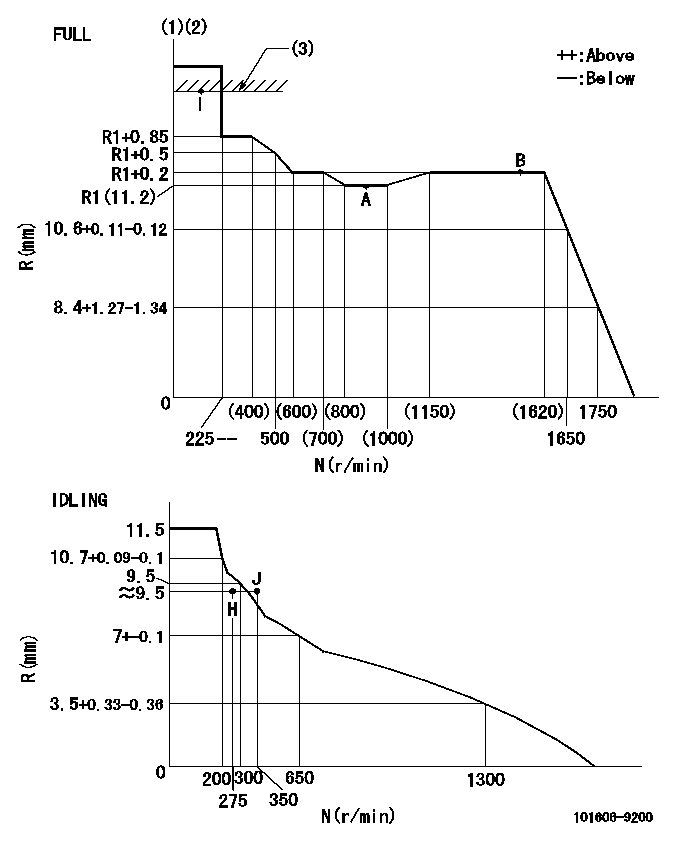

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

T1=H02

----------

----------

T1=H02

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=36mm

----------

a=27.5deg+-5deg b=40deg+-3deg

----------

aa=36mm

----------

a=27.5deg+-5deg b=40deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

----------

aa=42mm

----------

a=40deg+-5deg b=27deg+-5deg

----------

aa=42mm

----------

a=40deg+-5deg b=27deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Turn the engine to (TDC) top center compression stroke for the No. 1 piston and install crankshaft flywheel timing pin. This will help when timing the camshaft when installing.

Wire used to hold cam roller followers up off camshaft. It is not necessary to remove the cylinder head. With the cylinder head in place, just wire the cam roller followers up off the camshaft and then remove the camshaft. 1. Remove camshaft retainer bolt (1) and remove camshaft assembly (2). The following steps are for the installation of the camshaft assembly.

Typical Example When installing the camshaft, rotating it both clockwise and counter clockwise directions will help prevent it from binding in the bearing bores.2. Put engine oil on the lobes and journals of the camshaft. Carefully install the camshaft. When installing the camshaft, be sure the number one cylinder is at (TDC) top dead center of the compression stroke with the timing pin installed in the flywheel. Camshaft timing is very important. Cam gear timing marks must line up with idler gear timing marks as illustrated. For more information about timing of engine, refer to Specifications module, Form No. SENR3908.

Camshaft Timing3. With the camshaft properly timed and positioned, install retaining bolt (1). Tighten bolt (1) to a torque of 48 7 N m (37 5 lb ft). Remove the wire that was used to hold the cam roller followers up off the camshaft.End By:a. install fuel transfer pumpb. install front coverc. install front pulley and damperd. install fuel injectorse. install rocker arm assemblies and push rodsDisassembly & Assembly of Camshaft And Gear Assembly

Start By:a. remove camshaft assembly 1. Wrap camshaft portion of camshaft and gear assembly (1) with paper towels to protect the camshaft from being damaged. 2. Remove six bolts (2). Remove timing/speed sensor ring gear (3). The timing/speed ring gear is located on gear (4) by dowel (6). Care must be taken not to damage timing/speed sensor ring gear (3) when removing. Using the prybar, work around the ring gear and pry the ring gear off a little at a time.

Care must be taken not to allow the camshaft to fall to the floor when pressing it from the gear. Also be sure that a camshaft lobe does not catch on the press plates.

3. Place camshaft and gear assembly (1) in a press. Press camshaft (5) from gear (4). The following steps are for the assembly of the camshaft and the gear assembly. 4. To install gear (4) on camshaft (5), place gear in the oven at 300°C (572°F) for 30 minutes and then install. Be sure the woodruff key is properly aligned and the gear is flush with the camshaft flange. 5. Align timing gear sensor ring gear (3) with dowel (6). "Front" is marked and visible when installing timing/speed ring gear sensor. Care must be taken not to damage the timing/speed sensor ring gear when installing. Using a mallet tap around the ring gear and drive it on a little at a

Wire used to hold cam roller followers up off camshaft. It is not necessary to remove the cylinder head. With the cylinder head in place, just wire the cam roller followers up off the camshaft and then remove the camshaft. 1. Remove camshaft retainer bolt (1) and remove camshaft assembly (2). The following steps are for the installation of the camshaft assembly.

Typical Example When installing the camshaft, rotating it both clockwise and counter clockwise directions will help prevent it from binding in the bearing bores.2. Put engine oil on the lobes and journals of the camshaft. Carefully install the camshaft. When installing the camshaft, be sure the number one cylinder is at (TDC) top dead center of the compression stroke with the timing pin installed in the flywheel. Camshaft timing is very important. Cam gear timing marks must line up with idler gear timing marks as illustrated. For more information about timing of engine, refer to Specifications module, Form No. SENR3908.

Camshaft Timing3. With the camshaft properly timed and positioned, install retaining bolt (1). Tighten bolt (1) to a torque of 48 7 N m (37 5 lb ft). Remove the wire that was used to hold the cam roller followers up off the camshaft.End By:a. install fuel transfer pumpb. install front coverc. install front pulley and damperd. install fuel injectorse. install rocker arm assemblies and push rodsDisassembly & Assembly of Camshaft And Gear Assembly

Start By:a. remove camshaft assembly 1. Wrap camshaft portion of camshaft and gear assembly (1) with paper towels to protect the camshaft from being damaged. 2. Remove six bolts (2). Remove timing/speed sensor ring gear (3). The timing/speed ring gear is located on gear (4) by dowel (6). Care must be taken not to damage timing/speed sensor ring gear (3) when removing. Using the prybar, work around the ring gear and pry the ring gear off a little at a time.

Care must be taken not to allow the camshaft to fall to the floor when pressing it from the gear. Also be sure that a camshaft lobe does not catch on the press plates.

3. Place camshaft and gear assembly (1) in a press. Press camshaft (5) from gear (4). The following steps are for the assembly of the camshaft and the gear assembly. 4. To install gear (4) on camshaft (5), place gear in the oven at 300°C (572°F) for 30 minutes and then install. Be sure the woodruff key is properly aligned and the gear is flush with the camshaft flange. 5. Align timing gear sensor ring gear (3) with dowel (6). "Front" is marked and visible when installing timing/speed ring gear sensor. Care must be taken not to damage the timing/speed sensor ring gear when installing. Using a mallet tap around the ring gear and drive it on a little at a

Have questions with 101606-9200?

Group cross 101606-9200 ZEXEL

Nissan-Diesel

101606-9200

9 400 615 556

16713Z6064

INJECTION-PUMP ASSEMBLY

FE6A

FE6A