Information injection-pump assembly

BOSCH

9 400 615 516

9400615516

ZEXEL

101606-6491

1016066491

MITSUBISHI

ME056830

me056830

Rating:

Service parts 101606-6491 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056371

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 615 516

9400615516

ZEXEL

101606-6491

1016066491

MITSUBISHI

ME056830

me056830

Zexel num

Bosch num

Firm num

Name

101606-6491

9 400 615 516

ME056830 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22 K

6D22 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

112

108.6

115.4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

18.5

15.7

21.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

112

111

113

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9.6)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

113.5

111

116

Difference in delivery

mm3/st.

9

9

9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

120

160

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

0.9

0.4

1.4

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

3

2.5

3.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

4

4

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

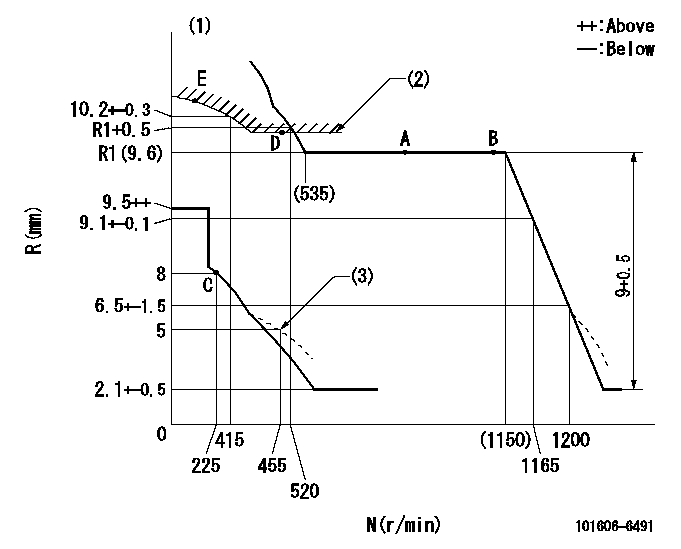

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Excess fuel setting for starting: SXL

(3)Damper spring setting

----------

SXL=R1+0.2mm

----------

----------

SXL=R1+0.2mm

----------

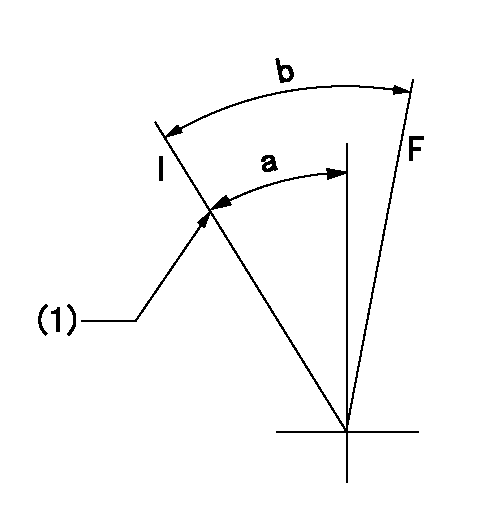

Speed control lever angle

F:Full speed

----------

----------

a=10deg+-5deg

----------

----------

a=10deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24deg+-5deg b=27.5deg+-3deg

----------

----------

a=24deg+-5deg b=27.5deg+-3deg

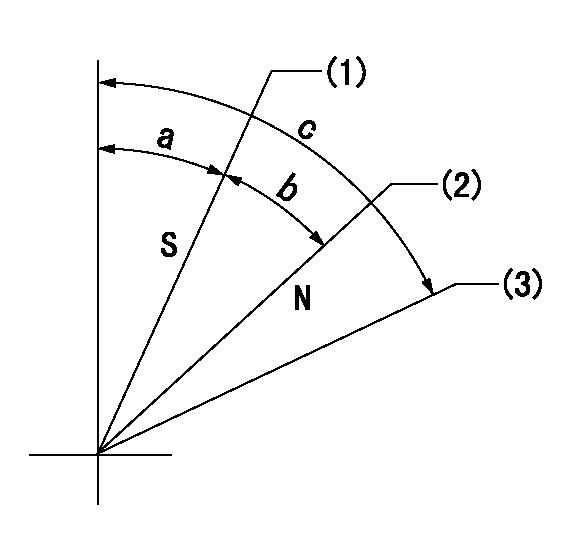

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, stopper bolt setting

(2)Rack position bb

(3)Free (at delivery)

----------

aa=5.5-0.5mm bb=16mm

----------

a=12.5deg+5deg-7deg b=34deg+-5deg c=(66.5deg)

----------

aa=5.5-0.5mm bb=16mm

----------

a=12.5deg+5deg-7deg b=34deg+-5deg c=(66.5deg)

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=7.3+-0.1mm

----------

----------

N1=325r/min Ra=7.3+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Do not disconnect any air lines until the air pressure is zero.

1. Loosen the bleed valves and release the air pressure in the air tanks.2. Drain the oil from the oil pan. 3. Remove two short bolts (1) and two longer bolts (3) from manifold (2) and the BrakeSaver housing. Remove manifold (2). Remove the O-ring seals from the manifold. 4. Remove oil temperature sensing unit (4) from the BrakeSaver control valve.5. Disconnect air line (5) and hose assembly (6) from the BrakeSaver control valve. 6. Remove bolt (7) and retainer (8) that hold the oil lines in the BrakeSaver control valve. 7. Disconnect oil lines (9) and (10) from the oil cooler. Remove oil lines (9) and (10) from the BrakeSaver control valve. 8. Remove bolts (12) and BrakeSaver control valve (11) from under the oil pan. The weight is 22 kg (48 lb.).9. Remove elbow (13) from the BrakeSaver control valve. Remove the O-ring seals. The following steps are for the installation of the BrakeSaver control valve.10. Inspect the O-ring seals for damage, and make replacements if needed. Put clean engine oil on the O-ring seals.11. Install the O-ring seals and elbow (13) on the BrakeSaver control valve.12. Make sure the O-ring seals are in position on the face of the BrakeSaver control valve. Put the BrakeSaver control valve (11) in position under the oil pan. Install bolts (12) that hold the BrakeSaver control valve to the oil pan.13. Install oil temperature sensing unit (4) in the BrakeSaver control valve.14. Connect air line (5) and hose assembly (6) to the BrakeSaver control valve.15. Install the O-ring seals on manifold (2). Install manifold (2) in the BrakeSaver control valve. Install the four bolts that hold the manifold to the BrakeSaver housing.16. Make sure the O-ring seals are in place on the oil lines, and install oil lines (9) and (10).17. Install retainer (8) to hold the oil lines in the BrakeSaver control valve. If the bottom plug in the oil pan was removed, put the split (seam) of the gasket for the plug against the oil pan. If either plug on the side of the oil pan was removed, put 5P3413 Pipe Sealant With Teflon on the threads, and tighten the plug to a torque of 80 11 N m (60 8 lb ft.).18. Fill the engine with oil to the correct level. See the maintenance Guide.Disassemble And Assemble BrakeSaver Control Valve

Start By:a. remove BrakeSaver control valve 1. Remove O-ring seals (1) from the valve body.

Covers (3) and (4) hold a spring under compression. To prevent possible personal injury from flying parts, hold covers (3) and (4) when the bolts are removed.

2. Remove four bolts (2) slowly and evenly from cover (4). Remove the cover.3. Remove cover (3) and the seal from the opposite end of the valve body. 4. Remove spool (8) as an assembly.5. Remove spring (7), stop (10), spring (6) and slug (9).6. Remove the O-ring seals and sleeve (5). 7. Remove

Have questions with 101606-6491?

Group cross 101606-6491 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

101606-6491

9 400 615 516

ME056830

INJECTION-PUMP ASSEMBLY

6D22

6D22