Information injection-pump assembly

BOSCH

9 400 615 472

9400615472

ZEXEL

101606-1873

1016061873

MITSUBISHI

ME076283

me076283

Rating:

Service parts 101606-1873 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME076088

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 615 472

9400615472

ZEXEL

101606-1873

1016061873

MITSUBISHI

ME076283

me076283

Zexel num

Bosch num

Firm num

Name

101606-1873

9 400 615 472

ME076283 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D15T2 K 14BF INJECTION PUMP ASSY PE6AD PE

6D15T2 K 14BF INJECTION PUMP ASSY PE6AD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.9

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

90.8

88.1

93.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.2

8.7

11.7

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.9)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

90.8

89.8

91.8

Basic

*

Fixing the lever

*

Boost pressure

kPa

41.3

41.3

Boost pressure

mmHg

310

310

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.15

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

104

100

108

Fixing the lever

*

Boost pressure

kPa

41.3

41.3

Boost pressure

mmHg

310

310

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.75

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

98.9

94.9

102.9

Fixing the lever

*

Boost pressure

kPa

41.3

41.3

Boost pressure

mmHg

310

310

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2-1.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

59.7

55.7

63.7

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

65

105

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

350

350

350

Rack position

R2-1.5

Boost pressure

kPa

8

8

8

Boost pressure

mmHg

60

60

60

Boost compensator adjustment_02

Pump speed

r/min

350

350

350

Rack position

R2-1.2

Boost pressure

kPa

12.7

11.4

14

Boost pressure

mmHg

95

85

105

Boost compensator adjustment_03

Pump speed

r/min

350

350

350

Rack position

R2(R1+0.

75)

Boost pressure

kPa

28

28

28

Boost pressure

mmHg

210

210

210

Timer adjustment

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1225

Advance angle

deg.

1.5

1

2

Timer adjustment_03

Pump speed

r/min

1300

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

Test data Ex:

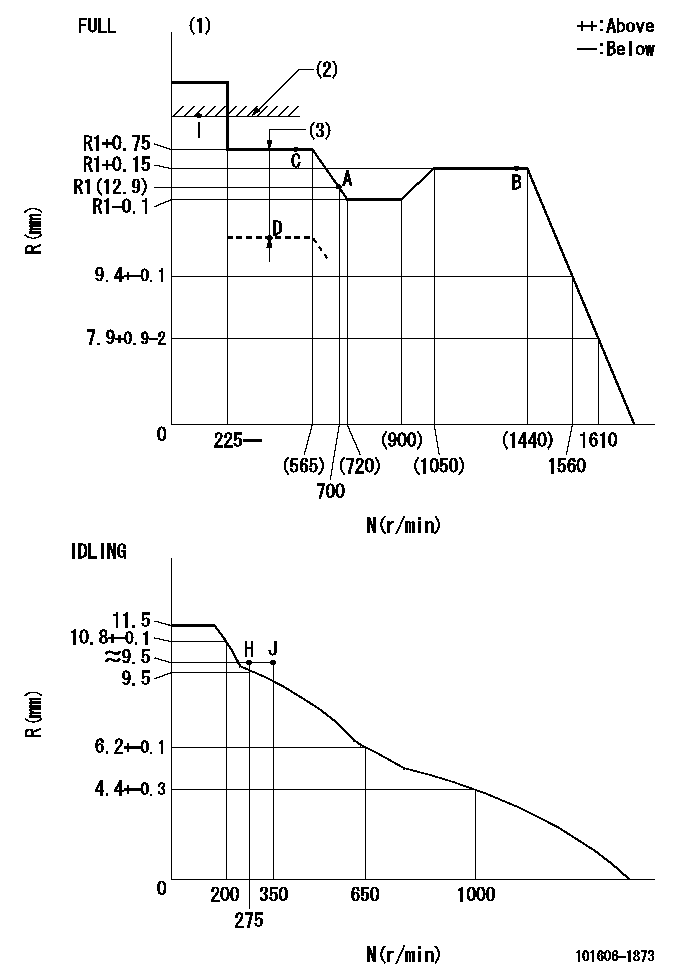

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)Boost compensator stroke: BCL

----------

T1=D59 BCL=1.5+-0.1mm

----------

----------

T1=D59 BCL=1.5+-0.1mm

----------

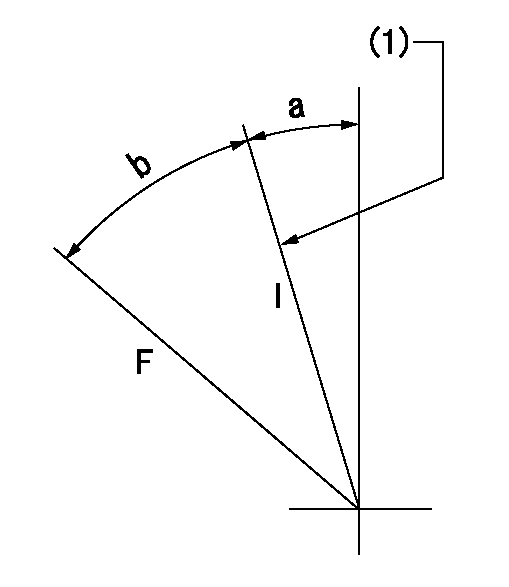

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=39deg+-3deg

----------

----------

a=18.5deg+-5deg b=39deg+-3deg

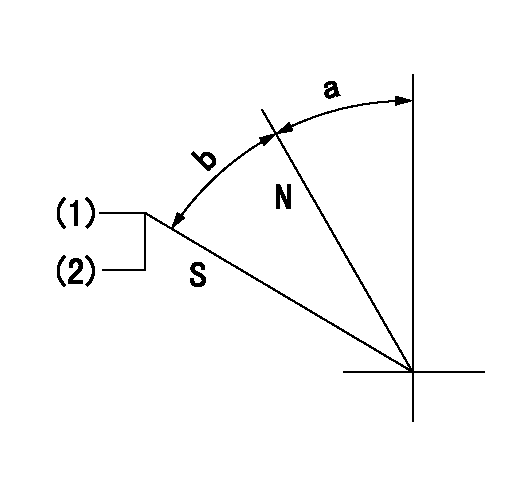

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

----------

aa=1350r/min bb=6.5-0.5mm cc=275r/min dd=(8.5)mm

----------

a=11.5deg+-5deg b=27deg+-5deg

----------

aa=1350r/min bb=6.5-0.5mm cc=275r/min dd=(8.5)mm

----------

a=11.5deg+-5deg b=27deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400r/min Ra=9.2+-0.1mm

----------

----------

N1=400r/min Ra=9.2+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(1deg)

----------

aa=11deg

----------

a=(1deg)

Information:

Gauges provide indications of engine performance. Be sure they are in good working order. You can determine what is the "normal" operating range by observing the gauges over a period of time.Noticeable changes in gauge readings indicate potential gauge or engine problems. This also applies to gauge readings that have changed significantly, but are still within specifications. The cause of any sudden or significant change in gauge readings should be determined and corrected. Contact your Caterpillar dealer for assistance as needed.

Oil Pressure - Indicated engine oil pressure. The oil pressure should be greatest after starting a cold engine. Oil pressure should read between 275 and 606 kPa (40 and 88 psi) when: the engine is running at rated engine speed with SAE 10W30 oil, with an oil temperature no more than 110°C (230°F). A lower pressure is normal at low idling speed.If the oil pressure readings fluctuate after the load has stabilized:1. Remove the load.2. Reduce the engine speed to low idle.3. Check the oil level, and add oil if necessary.The minimum recommended oil pressure at 600 rpm is 103 kPa (15 psi). If low oil pressure or no oil pressure is indicated, stop the engine and determine the cause of the problem. Refer to the Troubleshooting section of the Service Manual, or consult with your Caterpillar dealer.

Engine damage can result if the engine is operated with no oil pressure gauge reading. If no pressure is indicated, stop the engine.

Jacket Water Temperature - Indicates engine coolant temperature. It should normally indicate between 87 to 98°C (189 to 209°F). Higher temperatures may occur under certain conditions. Maximum allowable temperature is 104°C (220°F) with the cooling system pressurized.If the engine is operating with a jacket water temperature above this range:1. Reduce the load and rpm.2. Look for coolant leaks.3. Determine if the engine must be shut down immediately, or if the engine can be cooled by reducing the load.

Ammeter - Indicates the amount of charge or discharge in the battery charging circuit. Normal operation of the indicator should be slightly to the positive (right) side of "0" (zero).Check the charging system for malfunction if, during operation, the indicator is constantly to the negative (left) side of "0" (zero) or shows excessive charge.

Tachometer - Indicates engine rpm (speed). The engine can be operated at high idle without damage, but should not be allowed to overspeed. Overspeeding can seriously damage your engine.

Do not exceed "bare engine high idle" rpm in any situation.

Fuel Level - Indicates fuel level in the fuel tank. The electrically operated fuel level gauge registers only when the START/STOP (ignition key) switch is ON.

Fuel Pressure - Indicates fuel pressure to the injection pump. The indicator should register in the NORMAL (green) range.If the indicator moves to the OUT position or registers below 160 kPa (23 psi) when equipped with a numerical gauge, the engine will not operate properly. In most cases this is caused by a plugged fuel filter.

Service Hour Meter - Indicates the total number of service meter

Oil Pressure - Indicated engine oil pressure. The oil pressure should be greatest after starting a cold engine. Oil pressure should read between 275 and 606 kPa (40 and 88 psi) when: the engine is running at rated engine speed with SAE 10W30 oil, with an oil temperature no more than 110°C (230°F). A lower pressure is normal at low idling speed.If the oil pressure readings fluctuate after the load has stabilized:1. Remove the load.2. Reduce the engine speed to low idle.3. Check the oil level, and add oil if necessary.The minimum recommended oil pressure at 600 rpm is 103 kPa (15 psi). If low oil pressure or no oil pressure is indicated, stop the engine and determine the cause of the problem. Refer to the Troubleshooting section of the Service Manual, or consult with your Caterpillar dealer.

Engine damage can result if the engine is operated with no oil pressure gauge reading. If no pressure is indicated, stop the engine.

Jacket Water Temperature - Indicates engine coolant temperature. It should normally indicate between 87 to 98°C (189 to 209°F). Higher temperatures may occur under certain conditions. Maximum allowable temperature is 104°C (220°F) with the cooling system pressurized.If the engine is operating with a jacket water temperature above this range:1. Reduce the load and rpm.2. Look for coolant leaks.3. Determine if the engine must be shut down immediately, or if the engine can be cooled by reducing the load.

Ammeter - Indicates the amount of charge or discharge in the battery charging circuit. Normal operation of the indicator should be slightly to the positive (right) side of "0" (zero).Check the charging system for malfunction if, during operation, the indicator is constantly to the negative (left) side of "0" (zero) or shows excessive charge.

Tachometer - Indicates engine rpm (speed). The engine can be operated at high idle without damage, but should not be allowed to overspeed. Overspeeding can seriously damage your engine.

Do not exceed "bare engine high idle" rpm in any situation.

Fuel Level - Indicates fuel level in the fuel tank. The electrically operated fuel level gauge registers only when the START/STOP (ignition key) switch is ON.

Fuel Pressure - Indicates fuel pressure to the injection pump. The indicator should register in the NORMAL (green) range.If the indicator moves to the OUT position or registers below 160 kPa (23 psi) when equipped with a numerical gauge, the engine will not operate properly. In most cases this is caused by a plugged fuel filter.

Service Hour Meter - Indicates the total number of service meter

Have questions with 101606-1873?

Group cross 101606-1873 ZEXEL

Mitsubishi

101606-1873

9 400 615 472

ME076283

INJECTION-PUMP ASSEMBLY

6D15T2

6D15T2