Information injection-pump assembly

ZEXEL

101606-1800

1016061800

MITSUBISHI

ME076231

me076231

Rating:

Cross reference number

ZEXEL

101606-1800

1016061800

MITSUBISHI

ME076231

me076231

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.2

4.15

4.25

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.5

Pump speed

r/min

800

800

800

Each cylinder's injection qty

mm3/st.

90.5

87.8

93.2

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.2

8.7

11.7

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.5)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

90.5

89.5

91.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

41.3

41.3

Boost pressure

mmHg

310

310

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.25

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

101.8

97.8

105.8

Fixing the lever

*

Boost pressure

kPa

41.3

41.3

Boost pressure

mmHg

310

310

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.75

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

99.2

95.2

103.2

Fixing the lever

*

Boost pressure

kPa

41.3

41.3

Boost pressure

mmHg

310

310

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2-0.9

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

68

64

72

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

65

105

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

350

350

350

Rack position

R2-0.9

Boost pressure

kPa

8

8

8

Boost pressure

mmHg

60

60

60

Boost compensator adjustment_02

Pump speed

r/min

350

350

350

Rack position

R2-0.7

Boost pressure

kPa

12

10.7

13.3

Boost pressure

mmHg

90

80

100

Boost compensator adjustment_03

Pump speed

r/min

350

350

350

Rack position

R2(R1+0.

75)

Boost pressure

kPa

28

28

28

Boost pressure

mmHg

210

210

210

Timer adjustment

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1225

Advance angle

deg.

1.5

1

2

Timer adjustment_03

Pump speed

r/min

1300

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

Test data Ex:

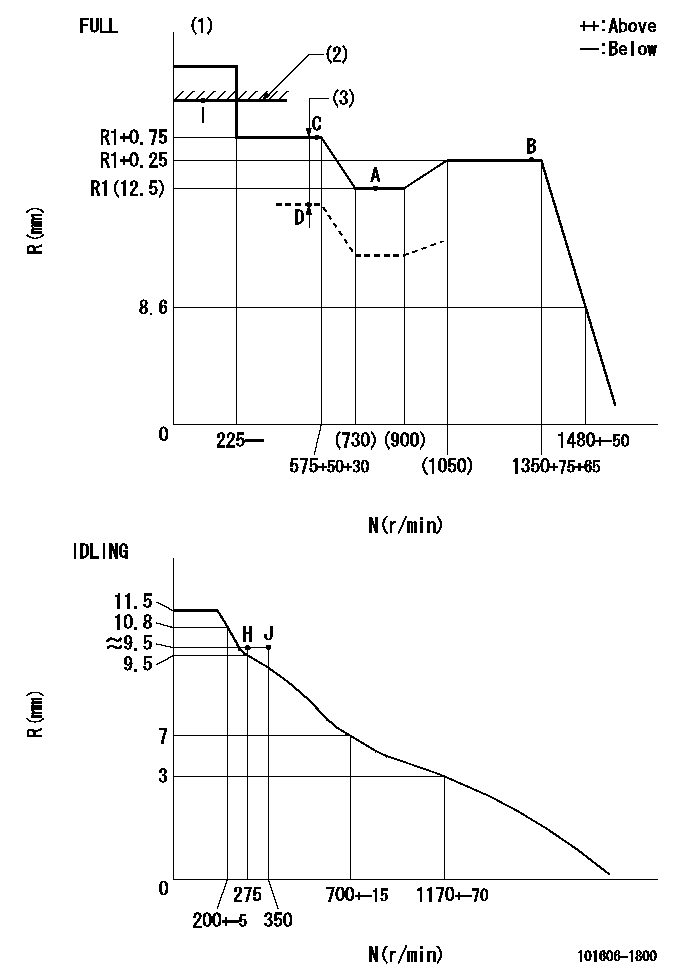

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)Boost compensator stroke: BCL

----------

T1=D12 BCL=0.9+-0.1mm

----------

----------

T1=D12 BCL=0.9+-0.1mm

----------

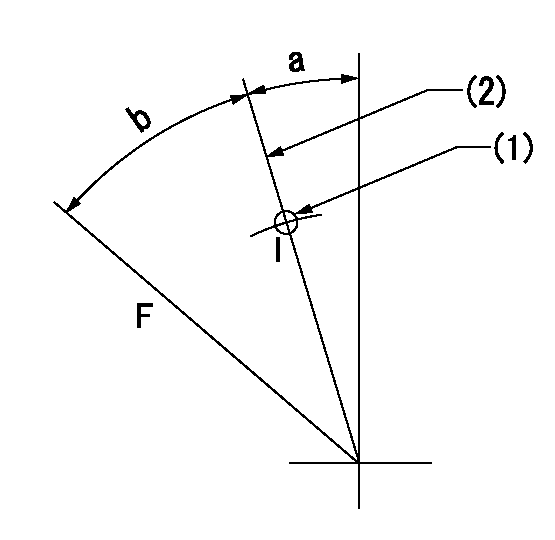

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=29mm

----------

a=10deg+-5deg b=44deg+-3deg

----------

aa=29mm

----------

a=10deg+-5deg b=44deg+-3deg

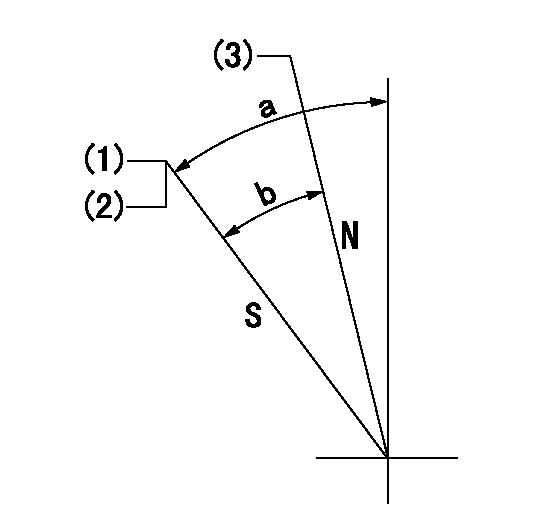

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

(3)Rack position = approximately ee.

----------

aa=1350r/min bb=6.5-0.5mm cc=275r/min dd=(8.5)mm ee=17.4mm

----------

a=38.5deg+-5deg b=19deg+-5deg

----------

aa=1350r/min bb=6.5-0.5mm cc=275r/min dd=(8.5)mm ee=17.4mm

----------

a=38.5deg+-5deg b=19deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.2mm

----------

----------

N1=400+-5r/min Ra=9.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(1deg)

----------

aa=11deg

----------

a=(1deg)

Information:

Industrial Rating Definitions

The application examples are listed for reference only. Refer to the specific application information and guidelines within the Technical Marketing Information for exact rating determination.A Rating (Continuous)

* For heavy-duty service when engine is operated at rated load and speed up to 100 percent of the time without interruption or load cycling.* Time at full load up to 100 percent of the duty cycle.* Typical examples are: pipeline pumping, ventilation, and customer specifications.B Rating

* For servicing where power and/or speed are cyclic.* Time at full load not to exceed 80 percent of the duty cycle.* Typical examples are: irrigation where normal pump demand is 85 percent of the duty cycle, oil field mechanical pumping and drilling, and stationary/plant air compressors.C Rating (Intermittent)

* For service where power and/or speed are cyclic* The horsepower and speed capability of the engine can be used for one uninterrupted hour, followed by one hour of operation at or below the A rating.* Time at full load not to exceed 50 percent of the duty cycle.* Typical examples are: agricultural tractors, harvesters and combines, off-highway trucks, fire pump application power, blast hole drills, rock crushers and wood chippers with high torque rise, and oil field hoisting.D Rating

* For service when rated power is required for periodic overloads.* The maximum horsepower and speed capability of the engine can be used for a maximum of 30 uninterrupted minutes, followed by one hour of followed by one hour of C rating operation.* Time at full load not to exceed 10 percent of the duty cycle.* Typical examples are: offshore cranes, runway snow blowers, water well drills, portable air compressors, and fire pump certification power.E Rating

* For service where rated power is required for a short time for initial starting or sudden overload. For emergency service where standard power is unavailable.* The maximum horsepower and speed capability of the engine can be utilized for a maximum of 15 uninterrupted minutes, followed by one hour at C rating operation, or for the duration of the emergency.* Time at full load is not to exceed 5 percent of the duty cycle.* Typical examples are: standby centrifugal water pumps, oil field well servicing, crash trucks, and gas turbine starters.Rating Conditions

Unless otherwise specified, all ratings are based on SAE J1349 standard ambient conditions:* 100 kPa (29.6 inches of Hg) of pressure* 30 percent relative humidity, and* a temperature of 26°C (77°F).Ratings also apply at AS1501, BS5514, DIN6271, and ISO3046/1 standard conditions.Power for diesel engines is based on:* API gravity of 35 at 15°C (60°F),* fuel LHV of 42.780 kJ/g (18390 Btu/lb) at 29°C (84°F), and* fuel density of 838.9 g/L (7.0001 lb/US gal)Ratings are gross output ratings- the total output capability of the engine-equipped with standard accessories. Standard accessories include pumps for lubrication oil, fuel, and jacket water, and magneto as required. The gross output, minus the power required to drive auxiliary components, equals the net power available for the external (flywheel) load. Typical auxiliary components include cooling fans, air compressors,

The application examples are listed for reference only. Refer to the specific application information and guidelines within the Technical Marketing Information for exact rating determination.A Rating (Continuous)

* For heavy-duty service when engine is operated at rated load and speed up to 100 percent of the time without interruption or load cycling.* Time at full load up to 100 percent of the duty cycle.* Typical examples are: pipeline pumping, ventilation, and customer specifications.B Rating

* For servicing where power and/or speed are cyclic.* Time at full load not to exceed 80 percent of the duty cycle.* Typical examples are: irrigation where normal pump demand is 85 percent of the duty cycle, oil field mechanical pumping and drilling, and stationary/plant air compressors.C Rating (Intermittent)

* For service where power and/or speed are cyclic* The horsepower and speed capability of the engine can be used for one uninterrupted hour, followed by one hour of operation at or below the A rating.* Time at full load not to exceed 50 percent of the duty cycle.* Typical examples are: agricultural tractors, harvesters and combines, off-highway trucks, fire pump application power, blast hole drills, rock crushers and wood chippers with high torque rise, and oil field hoisting.D Rating

* For service when rated power is required for periodic overloads.* The maximum horsepower and speed capability of the engine can be used for a maximum of 30 uninterrupted minutes, followed by one hour of followed by one hour of C rating operation.* Time at full load not to exceed 10 percent of the duty cycle.* Typical examples are: offshore cranes, runway snow blowers, water well drills, portable air compressors, and fire pump certification power.E Rating

* For service where rated power is required for a short time for initial starting or sudden overload. For emergency service where standard power is unavailable.* The maximum horsepower and speed capability of the engine can be utilized for a maximum of 15 uninterrupted minutes, followed by one hour at C rating operation, or for the duration of the emergency.* Time at full load is not to exceed 5 percent of the duty cycle.* Typical examples are: standby centrifugal water pumps, oil field well servicing, crash trucks, and gas turbine starters.Rating Conditions

Unless otherwise specified, all ratings are based on SAE J1349 standard ambient conditions:* 100 kPa (29.6 inches of Hg) of pressure* 30 percent relative humidity, and* a temperature of 26°C (77°F).Ratings also apply at AS1501, BS5514, DIN6271, and ISO3046/1 standard conditions.Power for diesel engines is based on:* API gravity of 35 at 15°C (60°F),* fuel LHV of 42.780 kJ/g (18390 Btu/lb) at 29°C (84°F), and* fuel density of 838.9 g/L (7.0001 lb/US gal)Ratings are gross output ratings- the total output capability of the engine-equipped with standard accessories. Standard accessories include pumps for lubrication oil, fuel, and jacket water, and magneto as required. The gross output, minus the power required to drive auxiliary components, equals the net power available for the external (flywheel) load. Typical auxiliary components include cooling fans, air compressors,