Information injection-pump assembly

ZEXEL

101606-1790

1016061790

Rating:

Cross reference number

ZEXEL

101606-1790

1016061790

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-6220

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

48.8

47.2

50.4

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

10.3+-0.

5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

8

6.7

9.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

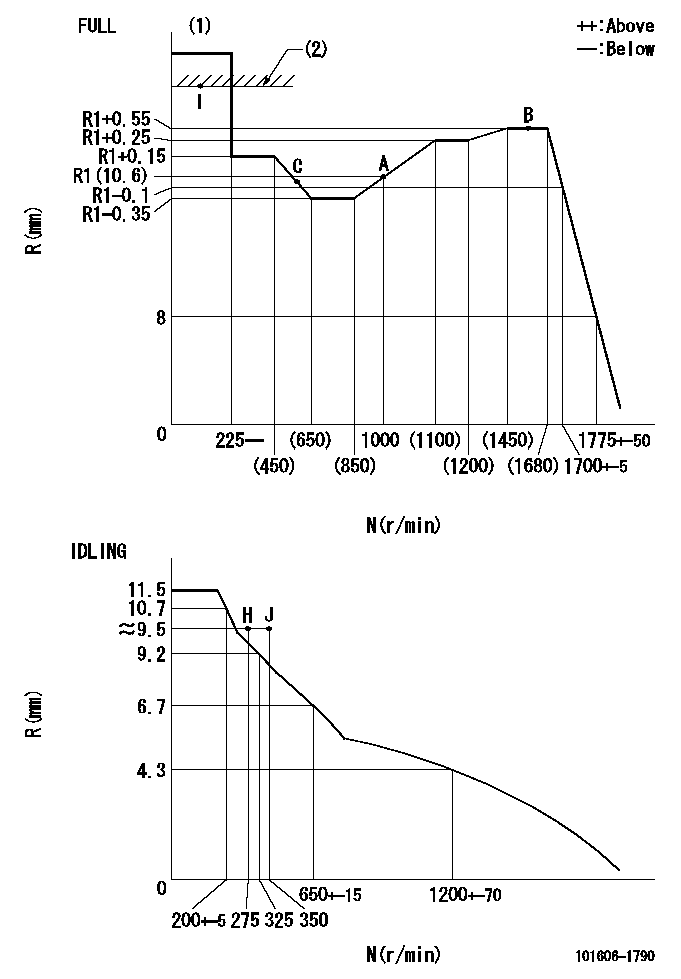

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.6)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

48.8

47.8

49.8

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.55

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

64.9

60.9

68.9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1-0.05

)

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

32.9

28.9

36.9

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60.5

60.5

65.5

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1500--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1450

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1600

Advance angle

deg.

3.5

3

4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=D19

----------

----------

T1=D19

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=40mm

----------

a=26deg+-5deg b=40deg+-3deg

----------

aa=40mm

----------

a=26deg+-5deg b=40deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Free (at shipping)

(2)Use the hole at R = aa

(3)Rack position corresponding to bb

(4)Set the stopper bolt so that speed = cc and rack position = dd. Confirm non-injection.

(5)After setting the stopper bolt, confirm non-injection at speed ee. (rack position = ff)

----------

aa=40mm bb=16mm cc=1700r/min dd=6.5-0.5mm ee=275r/min ff=8mm

----------

a=8deg+-5deg b=15deg+-5deg c=25deg+-5deg

----------

aa=40mm bb=16mm cc=1700r/min dd=6.5-0.5mm ee=275r/min ff=8mm

----------

a=8deg+-5deg b=15deg+-5deg c=25deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=9deg

----------

a=(1deg)

----------

aa=9deg

----------

a=(1deg)

Information:

Model Views

The sample model view drawings show various typical Caterpillar 3408C and 3412C Engine features. The drawings are generic and do not reflect all available options. Because of individual applications, your engine may appear different from those illustrated.

3408 Model Views:(1) Exhaust(2) Oil Level Gauge (Dipstick)(3) Crankcase Breather(4) Oil Filler Cap(5) Manual Shutoff Shaft(6) Lifting Eye(7) Fuel Priming Pump(8) Fuel Pressure Gauge(9) Fuel Filter(10) Oil Filter(11) Supplemental Coolant Additive Element(12) Oil Drain(13) Air Inlet(14) Turbocharger(15) and Magnetic Pickup Location.

3412 Model Views:(1) Exhaust(2) Oil Level Gauge (Dipstick)(3) Crankcase Breather(4) Oil Filler Cap(5) Manual Shutoff Shaft(6) Lifting Eye(7) Fuel Priming Pump(8) Fuel Pressure Gauge(9) Fuel Filter(10) Oil Filter(11) Supplemental Coolant Additive Element(12) Oil Drain(13) Air Inlet(14) Turbocharger(15) Magnetic Pickup LocationEngine Information

Engine Descriptions

The engines described in this publication are the 3408C and 3412C Industrial Diesel Engines. They are designed primarily for agricultural, petroleum, and auxiliary applications.A mechanical governor controls the fuel injection pump output, maintaining the engine rpm selected by the operator. Individual injection pumps (one for each cylinder) meter and pump fuel under high pressure to injection nozzles. Automatic timing advance provides the best fuel injection timing over the full range of engine speed.The fuel ratio control is located on the governor. The fuel ratio control restricts the fuel rack movement. Only the proper amount of fuel is allowed to be injected into the cylinders during acceleration. This minimizes exhaust smoke.Inlet air is filtered by an air cleaner. The air is compressed by a turbocharger before the air enters the engine cylinders. The turbocharger is driven by engine exhaust. The engines can be turbocharged, or turbocharged with jacket water aftercooling.The engines are four cycle engines. Each cylinder head has two inlet valves and two exhaust valves. The rocker arms and the valves are actuated by the camshaft. The action is performed by mechanical lifters and push rods.The cooling system consists of:* two thermostats (one for each bank) to regulate water temperature.* a gear driven centrifugal pump.* an oil cooler, and* a radiator (incorporating a shunt system).The engine lubricating oil, which is both cooled and filtered, is supplied by a gear-type pump. Bypass valves provide unrestricted flow of lubrication oil to the engine parts if oil viscosity is high, or if the oil cooler or the oil filter elements become plugged.Engine efficiency, efficiency of emission controls, and engine performance depend on adherence to proper operation and maintenance recommendations. Engine performance and efficiency also depend on the use of recommended coolant/antifreeze, fuels, and lubrication oils. Follow the recommended Maintenance Schedule found in this publication, paying attention to emission related components, air cleaner, oil, oil filter, fuel and fuel filter maintenance.

The sample model view drawings show various typical Caterpillar 3408C and 3412C Engine features. The drawings are generic and do not reflect all available options. Because of individual applications, your engine may appear different from those illustrated.

3408 Model Views:(1) Exhaust(2) Oil Level Gauge (Dipstick)(3) Crankcase Breather(4) Oil Filler Cap(5) Manual Shutoff Shaft(6) Lifting Eye(7) Fuel Priming Pump(8) Fuel Pressure Gauge(9) Fuel Filter(10) Oil Filter(11) Supplemental Coolant Additive Element(12) Oil Drain(13) Air Inlet(14) Turbocharger(15) and Magnetic Pickup Location.

3412 Model Views:(1) Exhaust(2) Oil Level Gauge (Dipstick)(3) Crankcase Breather(4) Oil Filler Cap(5) Manual Shutoff Shaft(6) Lifting Eye(7) Fuel Priming Pump(8) Fuel Pressure Gauge(9) Fuel Filter(10) Oil Filter(11) Supplemental Coolant Additive Element(12) Oil Drain(13) Air Inlet(14) Turbocharger(15) Magnetic Pickup LocationEngine Information

Engine Descriptions

The engines described in this publication are the 3408C and 3412C Industrial Diesel Engines. They are designed primarily for agricultural, petroleum, and auxiliary applications.A mechanical governor controls the fuel injection pump output, maintaining the engine rpm selected by the operator. Individual injection pumps (one for each cylinder) meter and pump fuel under high pressure to injection nozzles. Automatic timing advance provides the best fuel injection timing over the full range of engine speed.The fuel ratio control is located on the governor. The fuel ratio control restricts the fuel rack movement. Only the proper amount of fuel is allowed to be injected into the cylinders during acceleration. This minimizes exhaust smoke.Inlet air is filtered by an air cleaner. The air is compressed by a turbocharger before the air enters the engine cylinders. The turbocharger is driven by engine exhaust. The engines can be turbocharged, or turbocharged with jacket water aftercooling.The engines are four cycle engines. Each cylinder head has two inlet valves and two exhaust valves. The rocker arms and the valves are actuated by the camshaft. The action is performed by mechanical lifters and push rods.The cooling system consists of:* two thermostats (one for each bank) to regulate water temperature.* a gear driven centrifugal pump.* an oil cooler, and* a radiator (incorporating a shunt system).The engine lubricating oil, which is both cooled and filtered, is supplied by a gear-type pump. Bypass valves provide unrestricted flow of lubrication oil to the engine parts if oil viscosity is high, or if the oil cooler or the oil filter elements become plugged.Engine efficiency, efficiency of emission controls, and engine performance depend on adherence to proper operation and maintenance recommendations. Engine performance and efficiency also depend on the use of recommended coolant/antifreeze, fuels, and lubrication oils. Follow the recommended Maintenance Schedule found in this publication, paying attention to emission related components, air cleaner, oil, oil filter, fuel and fuel filter maintenance.