Information injection-pump assembly

ZEXEL

101606-1580

1016061580

Rating:

Cross reference number

ZEXEL

101606-1580

1016061580

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

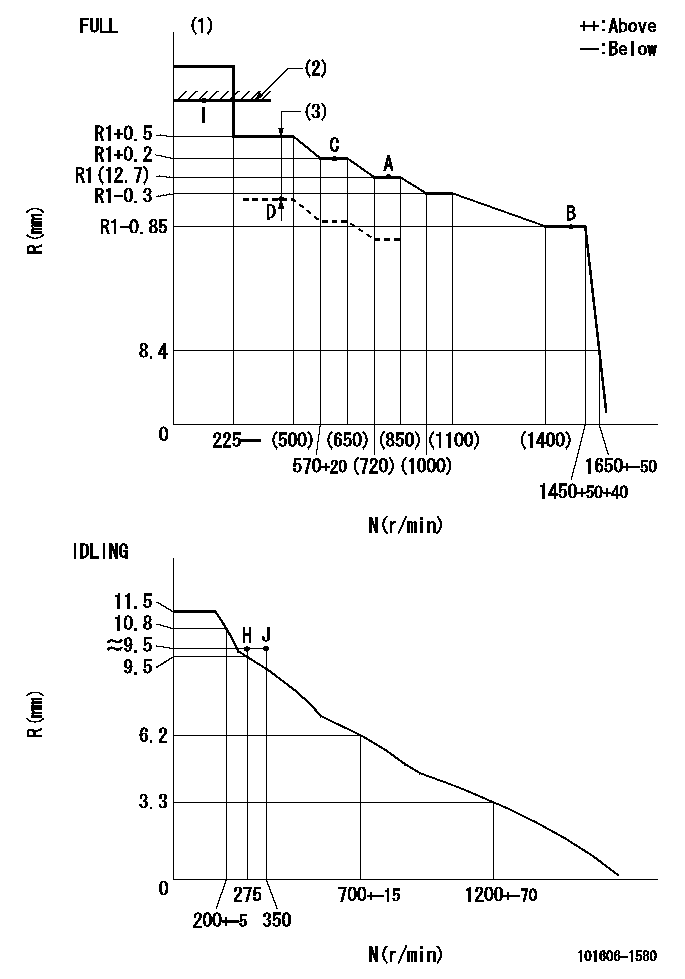

Injection quantity adjustment

Adjusting point

-

Rack position

12.7

Pump speed

r/min

800

800

800

Each cylinder's injection qty

mm3/st.

91.5

88.7

94.3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

8

6.8

9.2

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.7)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

91.5

90.5

92.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

36.7

36.7

Boost pressure

mmHg

275

275

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.85

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

85

81

89

Fixing the lever

*

Boost pressure

kPa

36.7

36.7

Boost pressure

mmHg

275

275

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1+0.2

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

91.2

87.2

95.2

Fixing the lever

*

Boost pressure

kPa

36.7

36.7

Boost pressure

mmHg

275

275

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2-0.9

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

59.9

55.9

63.9

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

99

79

119

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R2-0.9

Boost pressure

kPa

7.3

7.3

7.3

Boost pressure

mmHg

55

55

55

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

R2-0.7

Boost pressure

kPa

10.7

9.4

12

Boost pressure

mmHg

80

70

90

Boost compensator adjustment_03

Pump speed

r/min

300

300

300

Rack position

R2(R1+0.

5)

Boost pressure

kPa

23.3

23.3

23.3

Boost pressure

mmHg

175

175

175

Timer adjustment

Pump speed

r/min

1150++

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Do not advance until starting N = 1150.

Do not advance until starting N = 1150.

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Load

4/4

Timer adjustment_03

Pump speed

r/min

1300

Advance angle

deg.

1.7

1.2

2.2

Load

4/4

Timer adjustment_04

Pump speed

r/min

1400

Advance angle

deg.

3.5

3

4

Load

4/4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)Boost compensator stroke: BCL

----------

T1=C86 BCL=0.9+-0.1mm

----------

----------

T1=C86 BCL=0.9+-0.1mm

----------

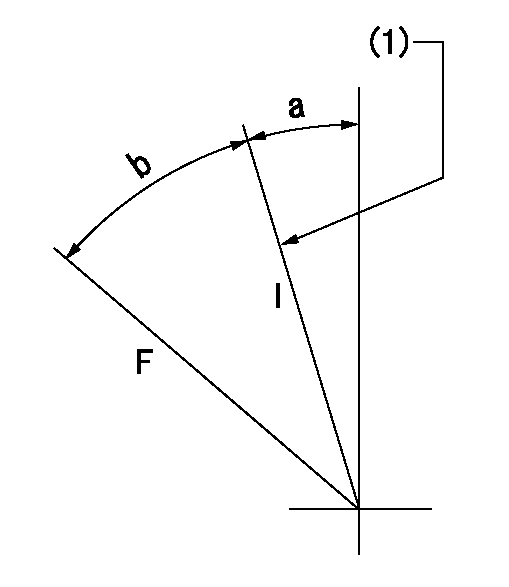

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=39deg+-3deg

----------

----------

a=18.5deg+-5deg b=39deg+-3deg

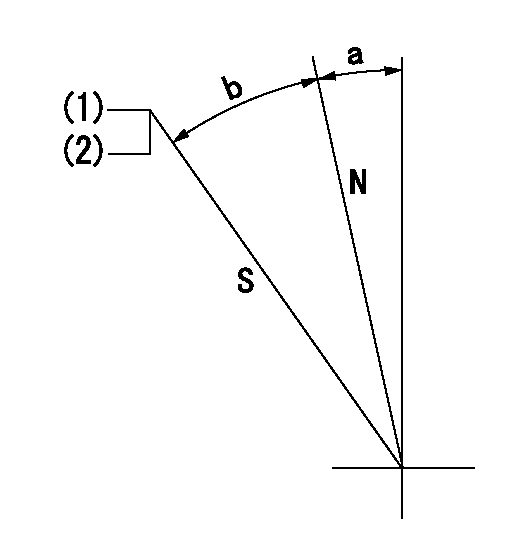

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at speed = rated point and rack position = aa (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt , confirm non-injection at pump speed bb. Rack position = cc (non-injection rack position).

----------

aa=(6.5)mm bb=275r/min cc=(6.5)mm

----------

a=11.5deg+-5deg b=(27deg)+-5deg

----------

aa=(6.5)mm bb=275r/min cc=(6.5)mm

----------

a=11.5deg+-5deg b=(27deg)+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.2mm

----------

----------

N1=400+-5r/min Ra=9.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

Generator Serial Number Plate

The generator Serial Number Plate is installed on the right side of the generator, near the front of the barrel. The generator serial number, model, and arrangement number are stamped on the Serial Number Plate.Generator Name Plate

The generator Name Plate is installed on the generator housing. The engine model, generator rating, and other generator data are stamped on the Name Plate.Reference Numbers

Fill in the blanks for future reference. Ordering Parts

When ordering parts, your order should specify the quantity, part number, part name and serial number, arrangement number and modification number of the engine for which the parts are needed. If in doubt about the part number, please provide your dealer with a complete description of the needed item.When service or maintenance is needed for your Caterpillar engine, be prepared to give the dealer all the information that is provided on the Information Plate.Discuss the problem with the dealer, such as when it occurs, what happens, etc. This will help the dealer in troubleshooting and solving the problem faster.Emissions Certification Film

Illustration 1

EPA/EU Emissions Certification Film (typical example)

Illustration 2

EPA/EU Emissions Certification Film (French-typical example)The EPA/EU Emissions Certification Film (if applicable) is located either on the side, the top, or the front of the engine.

The generator Serial Number Plate is installed on the right side of the generator, near the front of the barrel. The generator serial number, model, and arrangement number are stamped on the Serial Number Plate.Generator Name Plate

The generator Name Plate is installed on the generator housing. The engine model, generator rating, and other generator data are stamped on the Name Plate.Reference Numbers

Fill in the blanks for future reference. Ordering Parts

When ordering parts, your order should specify the quantity, part number, part name and serial number, arrangement number and modification number of the engine for which the parts are needed. If in doubt about the part number, please provide your dealer with a complete description of the needed item.When service or maintenance is needed for your Caterpillar engine, be prepared to give the dealer all the information that is provided on the Information Plate.Discuss the problem with the dealer, such as when it occurs, what happens, etc. This will help the dealer in troubleshooting and solving the problem faster.Emissions Certification Film

Illustration 1

EPA/EU Emissions Certification Film (typical example)

Illustration 2

EPA/EU Emissions Certification Film (French-typical example)The EPA/EU Emissions Certification Film (if applicable) is located either on the side, the top, or the front of the engine.