Information injection-pump assembly

ZEXEL

101606-1520

1016061520

Rating:

Cross reference number

ZEXEL

101606-1520

1016061520

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

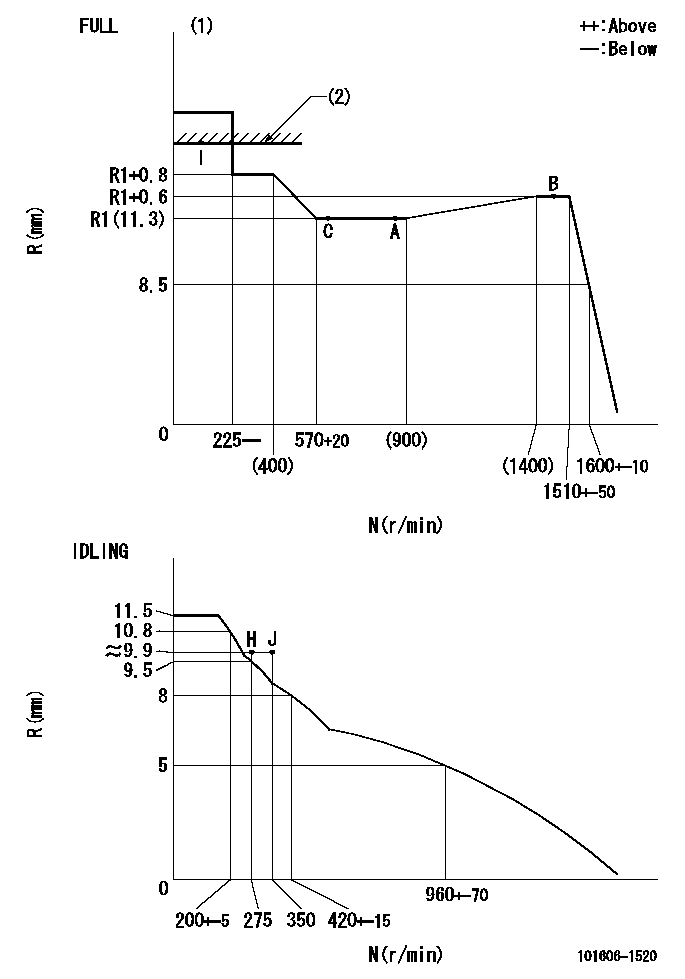

Injection quantity adjustment

Adjusting point

-

Rack position

11.3

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

65.4

63.5

67.3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.9+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

9.2

8.1

10.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

65.4

64.4

66.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.6

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

81.2

77.2

85.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1(11.3)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.5

45.5

53.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

2.4

1.9

2.9

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C69

----------

----------

T1=C69

----------

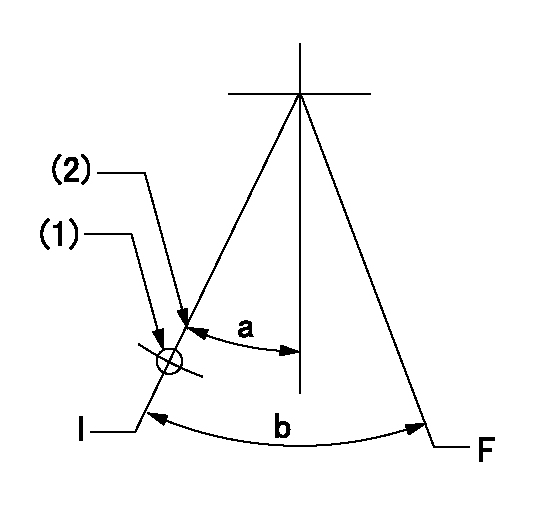

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=33deg+-5deg b=(42deg)+-3deg

----------

aa=35mm

----------

a=33deg+-5deg b=(42deg)+-3deg

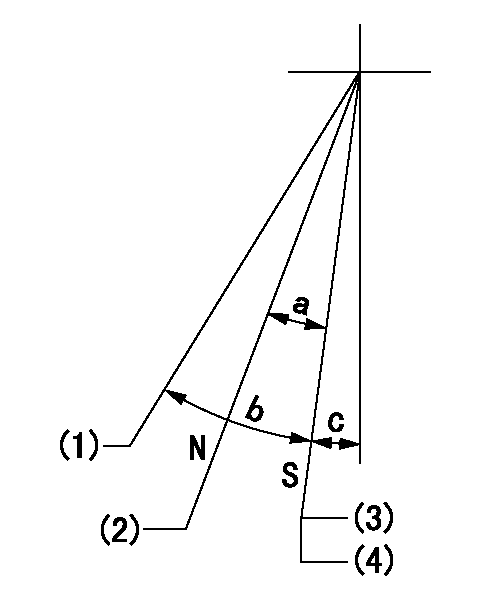

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Free (at shipping)

(2)Non-injection rack position

(3)Set the stopper bolt at speed = rated point and rack position = aa (non-injection rack position). Confirm non-injection.

(4)After setting the stopper bolt , confirm non-injection at pump speed bb. Rack position = cc (non-injection rack position).

----------

aa=(7)mm bb=275r/min cc=(8)mm

----------

a=17deg+-5deg b=(27deg) c=2deg+-5deg

----------

aa=(7)mm bb=275r/min cc=(8)mm

----------

a=17deg+-5deg b=(27deg) c=2deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.7mm

----------

----------

N1=400+-5r/min Ra=9.7mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

General

The objective of this information is to assist users in establishing a Preventive Maintenance Program for Standby Generator Sets or as an aid in evaluating their present programs.Standby Generator Sets may not be needed very often, but when they are, it is usually under emergency conditions. Maintenance of these standby units is very important. They must always be in excellent operating condition, ready to work under load at any time.Establishing a Preventive Maintenance Program will provide maximum availability of a standby generator set when needed, longer engine and generator life, and a minimum of expensive repairs.The recommended weekly maintenance checks can be performed by an operator. All yearly and three year maintenance should be performed by an authorized mechanic or your Caterpillar dealer.These guidelines are to be used with the information contained in the Operation and Maintenance Sections of this guide. The Operation and Maintenance sections of the guide will provide the necessary information on how to perform the checks and routine maintenance. Additional information can be obtained from the Generator and Engine Service Manuals, or contact your Caterpillar dealer for assistance.Inspection and Maintenance Agreements

Your Caterpillar dealer can establish an Inspection and Preventive Maintenance Program for your generator set to provide maximum reliability, increased engine and generator life, and minimize expensive repairs. Contact your Caterpillar dealer for details.Safety

Always make repairs with the engine stopped and the starting system disabled. When servicing the generator, make sure that switch gear and automatic transfer switches will not present a shock hazard. Lock them out on the generator being serviced.Record Keeping

Maintain a log or record keeping system to document all gauge readings, problems, repairs, and maintenance performed on the equipment.Space Heaters

Moisture is a natural enemy of generators and all electrical equipment. Every effort must be made to keep the generator as dry as possible. Space heaters should be operated inside the generator when it is not in use to maintain integrity of the generator windings.

Failure to comply with the following could result in personal injury or death.

* The Stop-Manual-Automatic (Auto Start/Stop) switch on the cranking panel must be at STOP position when performing maintenance or repair work on a standby generator set. This prevents the unit from starting if a power failure or voltage drop should occur while working on the unit. * To prevent personal injury due to accidental starting of the engine, disconnect the batteries or disable the starting system before doing maintenance or repair work.* Lock out all switch gear and automatic transfer switches associated with the generator while performing maintenance or repairs. Make sure no shock hazard exists.

The objective of this information is to assist users in establishing a Preventive Maintenance Program for Standby Generator Sets or as an aid in evaluating their present programs.Standby Generator Sets may not be needed very often, but when they are, it is usually under emergency conditions. Maintenance of these standby units is very important. They must always be in excellent operating condition, ready to work under load at any time.Establishing a Preventive Maintenance Program will provide maximum availability of a standby generator set when needed, longer engine and generator life, and a minimum of expensive repairs.The recommended weekly maintenance checks can be performed by an operator. All yearly and three year maintenance should be performed by an authorized mechanic or your Caterpillar dealer.These guidelines are to be used with the information contained in the Operation and Maintenance Sections of this guide. The Operation and Maintenance sections of the guide will provide the necessary information on how to perform the checks and routine maintenance. Additional information can be obtained from the Generator and Engine Service Manuals, or contact your Caterpillar dealer for assistance.Inspection and Maintenance Agreements

Your Caterpillar dealer can establish an Inspection and Preventive Maintenance Program for your generator set to provide maximum reliability, increased engine and generator life, and minimize expensive repairs. Contact your Caterpillar dealer for details.Safety

Always make repairs with the engine stopped and the starting system disabled. When servicing the generator, make sure that switch gear and automatic transfer switches will not present a shock hazard. Lock them out on the generator being serviced.Record Keeping

Maintain a log or record keeping system to document all gauge readings, problems, repairs, and maintenance performed on the equipment.Space Heaters

Moisture is a natural enemy of generators and all electrical equipment. Every effort must be made to keep the generator as dry as possible. Space heaters should be operated inside the generator when it is not in use to maintain integrity of the generator windings.

Failure to comply with the following could result in personal injury or death.

* The Stop-Manual-Automatic (Auto Start/Stop) switch on the cranking panel must be at STOP position when performing maintenance or repair work on a standby generator set. This prevents the unit from starting if a power failure or voltage drop should occur while working on the unit. * To prevent personal injury due to accidental starting of the engine, disconnect the batteries or disable the starting system before doing maintenance or repair work.* Lock out all switch gear and automatic transfer switches associated with the generator while performing maintenance or repairs. Make sure no shock hazard exists.