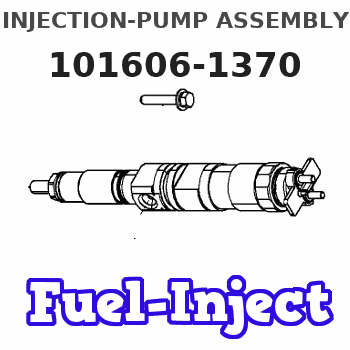

Information injection-pump assembly

BOSCH

9 400 615 443

9400615443

ZEXEL

101606-1370

1016061370

MITSUBISHI

ME056647

me056647

Rating:

Service parts 101606-1370 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)

15.

NOZZLE SET

Include in #1:

101606-1370

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-1811

as _

Cross reference number

Zexel num

Bosch num

Firm num

Name

9 400 615 443

ME056647 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22 * K 14BF INJECTION PUMP ASSY PE6AD PE

6D22 * K 14BF INJECTION PUMP ASSY PE6AD PE

Information:

Caterpillar recommends that the coolant mixture contain a minimum of 30% Caterpillar Antifreeze (or equivalent) with 70% distilled or deionized water to maintain an adequate cavitation temperature for efficient water pump performance. Antifreeze concentration should be selected to provide protection to the lowest expected outside (ambient) temperature.Check the specific gravity of the antifreeze solution frequently in cold weather to ensure adequate freeze protection. Premix coolant solution to provide protection to the lowest expected outside (ambient) temperature. Pure undiluted antifreeze will freeze at -10°F (-23°C). Antifreeze concentrations above 60% antifreeze to 40% water are NOT recommended because the higher concentrations limit the ability of the coolant mixture to absorb supplemental coolant additive.

Use Caterpillar Antifreeze or any low silicate (ethylene or propylene glycol) antifreeze that meets ASTM D4985-89 (GM Specification 6038-M) requirements. Most commercial antifreezes are formulated for gasoline engine applications and have high silicate content. Caterpillar Antifreeze is formulated with a low silicate content and the proper coolant additives for heavy duty diesel engines.Caterpillar Antifreeze is available through your Caterpillar dealer in quantities that follow. Adding pure undiluted antifreeze as a makeup solution for cooling system top-off is an unacceptable practice. Add antifreeze premixed with acceptable water to the same freeze protection as your cooling system. Use the Antifreeze Concentration chart to assist in determining the concentration of Caterpillar Antifreeze to use. Check the coolant solution frequently in cold weather for glycol concentration with the 5P0957 or 5P3514 Coolant Tester (for Caterpillar products) to ensure adequate freeze protection. The testers are identical except temperature scales (°C or °F) and give immediate accurate readings for antifreeze/coolants that contain ethylene or propylene glycol. Both testers are available at your Caterpillar dealer.

If propylene glycol based antifreeze is used, DO NOT allow concentration greater than a 50/50 antifreeze to water mixture. The measurement of freeze protection must be made with a refractive-type tester (5P0957 or 5P3514) rather than the hydrometer-type tester commercially available. The hydrometer-type tester can be used to test ethylene glycol based antifreeze.

Supplemental Coolant Additive (Conditioner or Inhibitor)

The cooling system MUST contain supplemental coolant additives (conditioner or inhibitor) to control corrosion, cavitation and deposits. It is also necessary to prevent rust, scale, pitting and/or corrosion of engine parts contacted by coolant. The cooling system should be protected with a minimum of 3% concentration at all times, regardless of the concentration of antifreeze. Use supplemental coolant additive liquid OR an element (if equipped) to maintain a 3-6% concentration in the cooling system.

Never use antifreeze/water coolant only, in Caterpillar engines without supplemental coolant additive regardless of antifreeze concentration.Caterpillar or other manufacturer's products can be used as the supplemental coolant additive. DO NOT mix Caterpillar Supplemental Coolant Additive (Conditioner) liquid or elements with the other commercial products available; select a cooling system treatment and use it exclusively.Excessive concentration of supplemental coolant additive can form deposits which may cause engine damage, reduce the engine's heat transfer characteristics and could also accelerate water pump seal wear.

Use the 8T5296 Test Kit to check