Information injection-pump assembly

BOSCH

9 400 615 437

9400615437

ZEXEL

101606-1310

1016061310

MITSUBISHI

ME056669

me056669

Rating:

Service parts 101606-1310 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Include in #1:

101606-1310

as INJECTION-PUMP ASSEMBLY

Include in #2:

104746-6062

as _

Cross reference number

BOSCH

9 400 615 437

9400615437

ZEXEL

101606-1310

1016061310

MITSUBISHI

ME056669

me056669

Zexel num

Bosch num

Firm num

Name

101606-1310

9 400 615 437

ME056669 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22 * K

6D22 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.45

4.55

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

112

108.6

115.4

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

18.5

15.7

21.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

112

111

113

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9.6)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

113.5

111

116

Difference in delivery

mm3/st.

9

9

9

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

120

160

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

0.9

0.4

1.4

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

3

2.5

3.5

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

4

4

5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

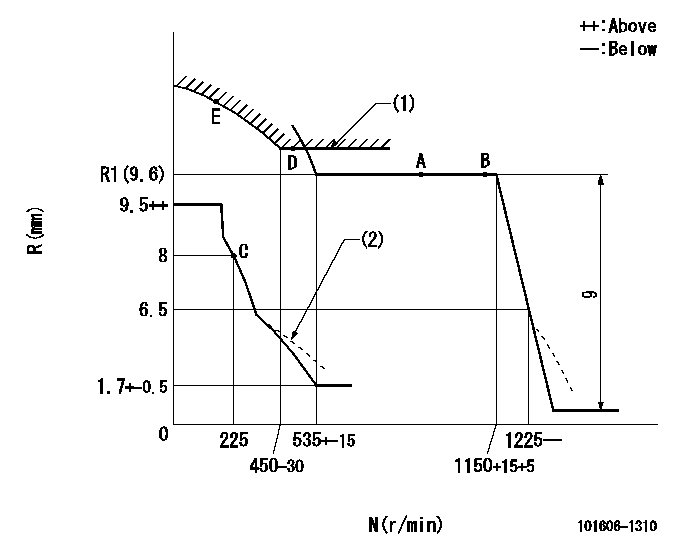

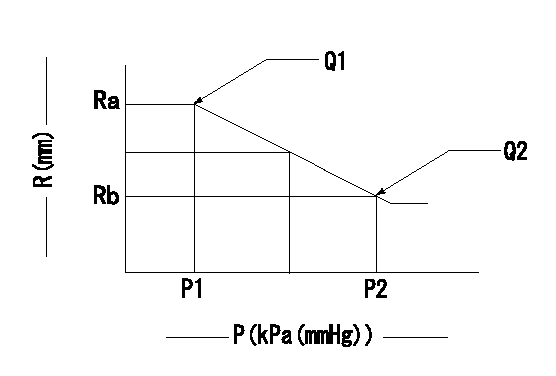

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Excess fuel setting for starting: SXL

(2)Damper spring setting: DL

----------

SXL=R1(9.6)+0.2mm DL=6-0.2mm

----------

----------

SXL=R1(9.6)+0.2mm DL=6-0.2mm

----------

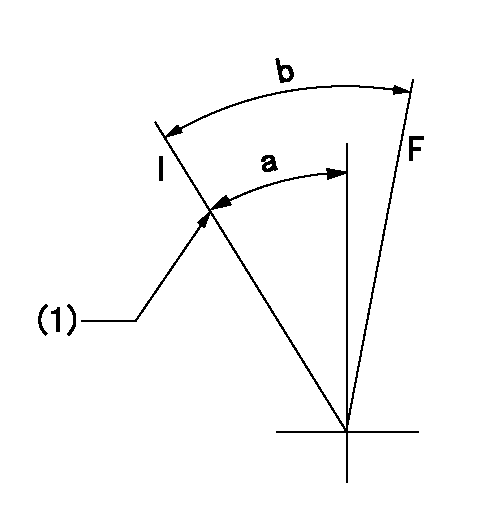

Speed control lever angle

F:Full speed

----------

----------

a=10deg+-5deg

----------

----------

a=10deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24deg+-5deg b=29deg+-3deg

----------

----------

a=24deg+-5deg b=29deg+-3deg

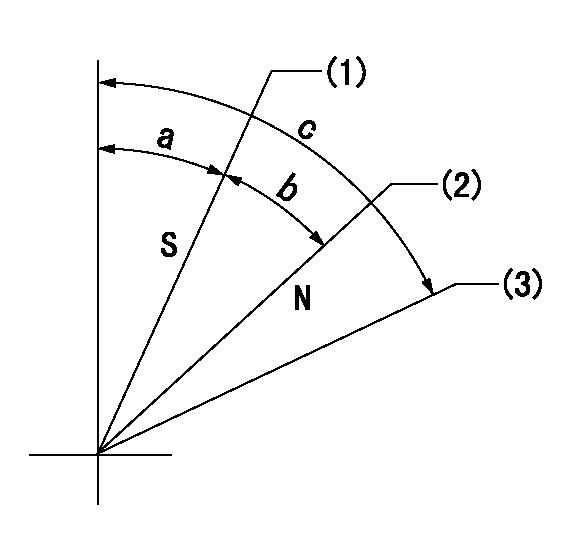

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, stopper bolt setting

(2)Rack position bb

(3)Free (at delivery)

----------

aa=5.5-0.5mm bb=16mm

----------

a=12.5deg+5deg-7deg b=34deg+-5deg c=(66.5deg)

----------

aa=5.5-0.5mm bb=16mm

----------

a=12.5deg+5deg-7deg b=34deg+-5deg c=(66.5deg)

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=7.3mm

----------

----------

N1=325+-5r/min Ra=7.3mm

----------

0000001601 ACS

Aneroid compensator adjustment

(1)Adjust the clearance between the aneroid compensator's main body and the push rod to L1.

(2)Pump speed N1 at load lever's full position.

(3)Screw in the aneroid compensator body to obtain the performance shown in the graph above.

----------

L1=0.1~0.5mm N1=700r/min

----------

Ra=9.6mm Rb=8.7mm P1=(88.8)kPa((666)mmHg) P2=69.3+-0.7kPa(520+-5mmHg) Q1=112+-1cm3/1000st Q2=-

----------

L1=0.1~0.5mm N1=700r/min

----------

Ra=9.6mm Rb=8.7mm P1=(88.8)kPa((666)mmHg) P2=69.3+-0.7kPa(520+-5mmHg) Q1=112+-1cm3/1000st Q2=-

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Use Again - if wear on contact surfaces cannot be felt with a seal pick.

Illustration 46 g06346577

Rack control and limiting sleeve.

Use Again - if wear on contact surfaces cannot be felt with a seal pick.Riser Shaft and Pin

Illustration 47 g06346580

Riser shaft.

Use Again - if there is no wear step on the shaft, which can be felt with a seal pick. If a step is present, it will generally occur near the center of the shaft.

Illustration 48 g06346583

Normal wear on pin at end of riser shaft.

Use Again

Illustration 49 g06346588

Pin with material eroded away near the center relief.

Do Not Use AgainFlyweight and Dowel

Illustration 50 g06346593

Flyweight toe with gouges near dowel hole.

Do Not Use Again - if wear marks can be felt with a seal pick.

Illustration 51 g06346599

Flyweight toe wear.

Do Not Use Again

Illustration 52 g06346602

Flyweight toe wear.

Do Not Use Again - if there are any signs of "flat spots". Worn flyweight toes may be highly polished so that flat spots are difficult to feel. Hold the flyweight toe surface in bright light and watch for changes in reflection in worn areas. Use a new flyweight toe for comparison.

Illustration 53 g06346609

Acceptable wear on flyweight dowel.

Use Again - if wear cannot be felt with a seal pick.

Illustration 54 g06346611

Heavy wear on flyweight dowel.

Do Not Use AgainNote: Examine the dowel seating area on the flyweight carrier. If there is any apparent wear, reinstall dowels in the unused positions, 90 degrees from original position.Bearing Assembly

Illustration 55 g06346614

The bearing (white collar) shown in position on the FARC diaphragm retainer (Type V, VI, and VII Governors) shows wear.

Do Not Use AgainGovernor Spring Seat

Illustration 56 g06346615

Governor spring seat with typical wear.

Use Again - if there are no gouges to surfaces (1) on the spring seating area.Spring Pack

Illustration 57 g06346618

End view of governor spring pack.

Use Again - after realignment.Note the off-center position of the internal springs with respect to the outside spring. This can cause governor instability, which results in surging. Rotate the springs on their seat so that the inner springs are aligned (centered) with respect to the outer spring. Remove sharp edges (A) from the inside diameter of the flat surface on the springs to ensure springs seat properly.

Illustration 46 g06346577

Rack control and limiting sleeve.

Use Again - if wear on contact surfaces cannot be felt with a seal pick.Riser Shaft and Pin

Illustration 47 g06346580

Riser shaft.

Use Again - if there is no wear step on the shaft, which can be felt with a seal pick. If a step is present, it will generally occur near the center of the shaft.

Illustration 48 g06346583

Normal wear on pin at end of riser shaft.

Use Again

Illustration 49 g06346588

Pin with material eroded away near the center relief.

Do Not Use AgainFlyweight and Dowel

Illustration 50 g06346593

Flyweight toe with gouges near dowel hole.

Do Not Use Again - if wear marks can be felt with a seal pick.

Illustration 51 g06346599

Flyweight toe wear.

Do Not Use Again

Illustration 52 g06346602

Flyweight toe wear.

Do Not Use Again - if there are any signs of "flat spots". Worn flyweight toes may be highly polished so that flat spots are difficult to feel. Hold the flyweight toe surface in bright light and watch for changes in reflection in worn areas. Use a new flyweight toe for comparison.

Illustration 53 g06346609

Acceptable wear on flyweight dowel.

Use Again - if wear cannot be felt with a seal pick.

Illustration 54 g06346611

Heavy wear on flyweight dowel.

Do Not Use AgainNote: Examine the dowel seating area on the flyweight carrier. If there is any apparent wear, reinstall dowels in the unused positions, 90 degrees from original position.Bearing Assembly

Illustration 55 g06346614

The bearing (white collar) shown in position on the FARC diaphragm retainer (Type V, VI, and VII Governors) shows wear.

Do Not Use AgainGovernor Spring Seat

Illustration 56 g06346615

Governor spring seat with typical wear.

Use Again - if there are no gouges to surfaces (1) on the spring seating area.Spring Pack

Illustration 57 g06346618

End view of governor spring pack.

Use Again - after realignment.Note the off-center position of the internal springs with respect to the outside spring. This can cause governor instability, which results in surging. Rotate the springs on their seat so that the inner springs are aligned (centered) with respect to the outer spring. Remove sharp edges (A) from the inside diameter of the flat surface on the springs to ensure springs seat properly.

Have questions with 101606-1310?

Group cross 101606-1310 ZEXEL

Mitsubishi

101606-1310

9 400 615 437

ME056669

INJECTION-PUMP ASSEMBLY

6D22

6D22