Information injection-pump assembly

BOSCH

9 400 615 435

9400615435

ZEXEL

101606-1280

1016061280

MITSUBISHI

ME035391

me035391

Rating:

Include in #2:

104746-6033

as _

Cross reference number

BOSCH

9 400 615 435

9400615435

ZEXEL

101606-1280

1016061280

MITSUBISHI

ME035391

me035391

Zexel num

Bosch num

Firm num

Name

101606-1280

9 400 615 435

ME035391 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D14 * K

6D14 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

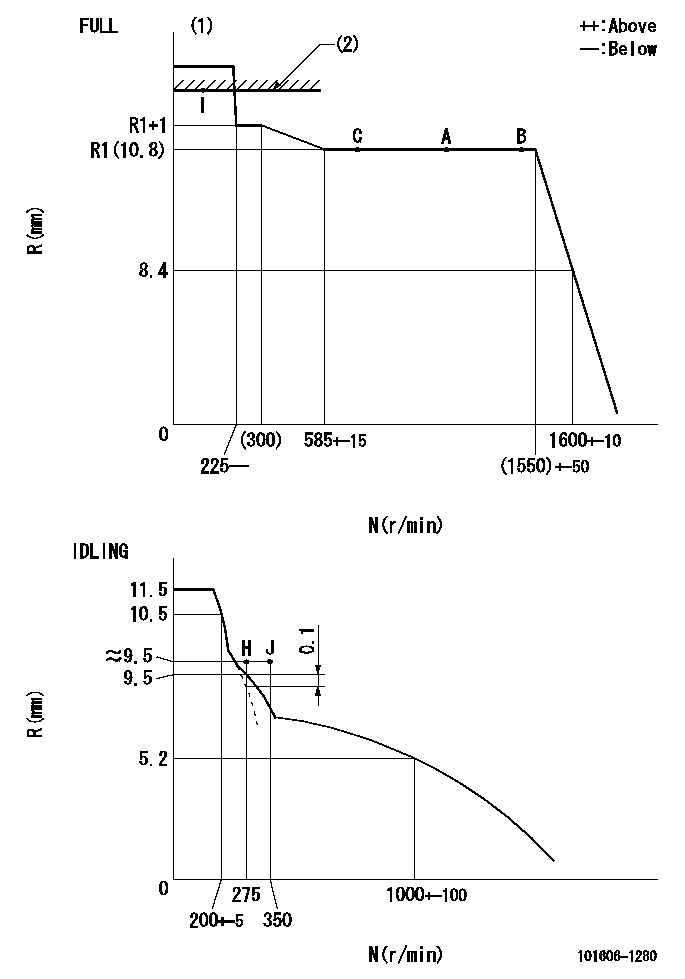

Injection quantity adjustment

Adjusting point

-

Rack position

10.8

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

65

63

67

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10.5

9

12

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.8)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

65

64

66

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(10.8)

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

77.5

75.5

79.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1(10.8)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

51.5

49.5

53.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

14.1+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

70

110

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

850

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.8

Timer adjustment_03

Pump speed

r/min

1200

Advance angle

deg.

2.6

2.1

3.1

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=A70

----------

----------

T1=A70

----------

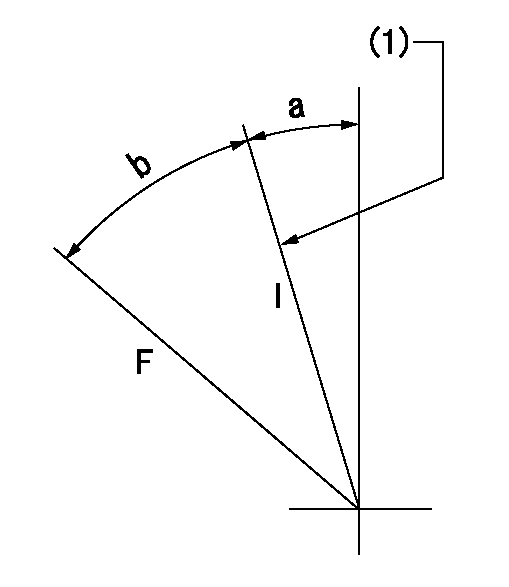

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=10deg+-5deg b=42deg+-3deg

----------

----------

a=10deg+-5deg b=42deg+-3deg

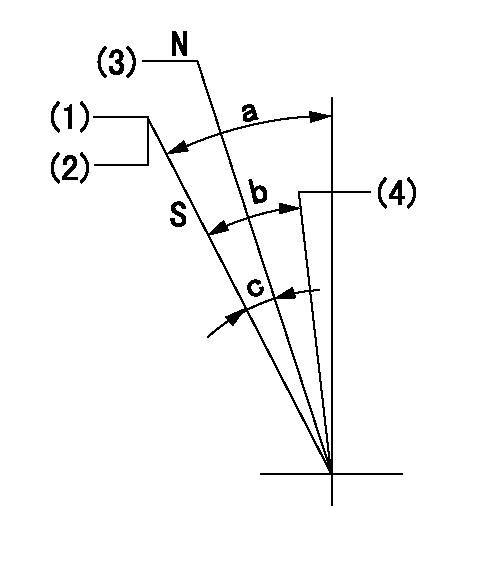

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at pump speed = aa and rack position = bb (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc. Rack position = dd (non-injection rack position).

(3)Rack position = approximately ee.

(4)Free (at shipping)

----------

aa=1550r/min bb=7.2mm cc=275r/min dd=8.2mm ee=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

----------

aa=1550r/min bb=7.2mm cc=275r/min dd=8.2mm ee=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(1deg)

----------

aa=16deg

----------

a=(1deg)

Information:

Engine Mounts

Inspect

Inspect the engine mounts for deterioration and proper bolt torque. Engine vibration may be caused by improper engine mounting and/or engine mount deterioration. Any engine mount showing deterioration should be replaced. Refer to the Torque Specifications section of this publication for recommended bolt torque values. See the Marine Engine Application and Installation Guide for more information.Crankshaft Vibration Damper

Inspect

Damage to, or failure of, the crankshaft vibration damper will increase torsional vibrations and result in damage to the crankshaft and other engine components. A deteriorating damper will cause excessive gear train noise at variable points in the speed range.The damper is mounted to the crankshaft, located behind the belt guard on the front of the engine.Removal and Installation

Refer to the Service Manual for the damper removal procedure and for the damper installation procedure.Visconic Damper

The visconic damper has a weight, located inside a fluid filled case. The weight moves in the case to limit torsional vibration. Inspect the damper for evidence of dents, cracks or leaks of the fluid.Replace the damper if the damper is dented, cracked, or leaking. Refer to the Service Manual or contact your Caterpillar dealer for damper replacement.Valve Lash

Check/Adjust

Initial valve lash adjustment on new, rebuilt or remanufactured engines is recommended at the first scheduled oil change interval due to initial wear and seating of valve train components.Subsequent adjustments should be made at Every 3000 Hour interval.This maintenance is recommended by Caterpillar as part of a lubrication and preventive maintenance schedule to provide maximum engine life.

Only qualified service personnel should perform this maintenance. Refer to the Service Manual or your Caterpillar dealer for the complete valve lash adjustment procedure.

Be sure the engine cannot be started while this maintenance is being performed. To prevent possible injury, do not use the starting motor to turn the flywheel.Hot engine components can cause burns. Allow additional time for the engine to cool before measuring/adjusting valve lash clearance.

Operation of Caterpillar engines with improper valve adjustments will reduce engine efficiency. This reduced efficiency could result in excessive fuel usage and/or shortened engine component life.

Valve Rotators

When inspecting the valve rotators, protective glasses or face shield and protective clothing must be worn, to prevent being burned by hot oil or spray.

A valve rotator which does not operate properly will accelerate valve face wear and valve seat wear and shorten valve life. If a damaged rotator is not replaced, valve face guttering could result and cause pieces of the valve to fall into the cylinder. This can cause piston and cylinder head damage.

After setting the valve lash and before installing the valve covers:1. Start the engine. Follow the engine starting procedure in this manual. Operate the engine at low idle.2. Observe the top surface of each valve rotator. Each valve rotator should turn slightly each time the valve closes.If a valve fails to rotate, contact your Caterpillar dealer.Fuel Ratio Control, Set Point, and Low Idle

Check/Adjust

The fuel ratio control limits the amount of fuel to the cylinders during acceleration. This affects the amount of exhaust smoke. The

Inspect

Inspect the engine mounts for deterioration and proper bolt torque. Engine vibration may be caused by improper engine mounting and/or engine mount deterioration. Any engine mount showing deterioration should be replaced. Refer to the Torque Specifications section of this publication for recommended bolt torque values. See the Marine Engine Application and Installation Guide for more information.Crankshaft Vibration Damper

Inspect

Damage to, or failure of, the crankshaft vibration damper will increase torsional vibrations and result in damage to the crankshaft and other engine components. A deteriorating damper will cause excessive gear train noise at variable points in the speed range.The damper is mounted to the crankshaft, located behind the belt guard on the front of the engine.Removal and Installation

Refer to the Service Manual for the damper removal procedure and for the damper installation procedure.Visconic Damper

The visconic damper has a weight, located inside a fluid filled case. The weight moves in the case to limit torsional vibration. Inspect the damper for evidence of dents, cracks or leaks of the fluid.Replace the damper if the damper is dented, cracked, or leaking. Refer to the Service Manual or contact your Caterpillar dealer for damper replacement.Valve Lash

Check/Adjust

Initial valve lash adjustment on new, rebuilt or remanufactured engines is recommended at the first scheduled oil change interval due to initial wear and seating of valve train components.Subsequent adjustments should be made at Every 3000 Hour interval.This maintenance is recommended by Caterpillar as part of a lubrication and preventive maintenance schedule to provide maximum engine life.

Only qualified service personnel should perform this maintenance. Refer to the Service Manual or your Caterpillar dealer for the complete valve lash adjustment procedure.

Be sure the engine cannot be started while this maintenance is being performed. To prevent possible injury, do not use the starting motor to turn the flywheel.Hot engine components can cause burns. Allow additional time for the engine to cool before measuring/adjusting valve lash clearance.

Operation of Caterpillar engines with improper valve adjustments will reduce engine efficiency. This reduced efficiency could result in excessive fuel usage and/or shortened engine component life.

Valve Rotators

When inspecting the valve rotators, protective glasses or face shield and protective clothing must be worn, to prevent being burned by hot oil or spray.

A valve rotator which does not operate properly will accelerate valve face wear and valve seat wear and shorten valve life. If a damaged rotator is not replaced, valve face guttering could result and cause pieces of the valve to fall into the cylinder. This can cause piston and cylinder head damage.

After setting the valve lash and before installing the valve covers:1. Start the engine. Follow the engine starting procedure in this manual. Operate the engine at low idle.2. Observe the top surface of each valve rotator. Each valve rotator should turn slightly each time the valve closes.If a valve fails to rotate, contact your Caterpillar dealer.Fuel Ratio Control, Set Point, and Low Idle

Check/Adjust

The fuel ratio control limits the amount of fuel to the cylinders during acceleration. This affects the amount of exhaust smoke. The

Have questions with 101606-1280?

Group cross 101606-1280 ZEXEL

Mitsubishi

Mitsubishi

101606-1280

9 400 615 435

ME035391

INJECTION-PUMP ASSEMBLY

6D14

6D14