Information injection-pump assembly

ZEXEL

101606-1260

1016061260

Rating:

Cross reference number

ZEXEL

101606-1260

1016061260

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.9

2.85

2.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

87

86

88

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.3+-0.5

Pump speed

r/min

385

385

385

Average injection quantity

mm3/st.

21.5

20

23

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

2

2

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

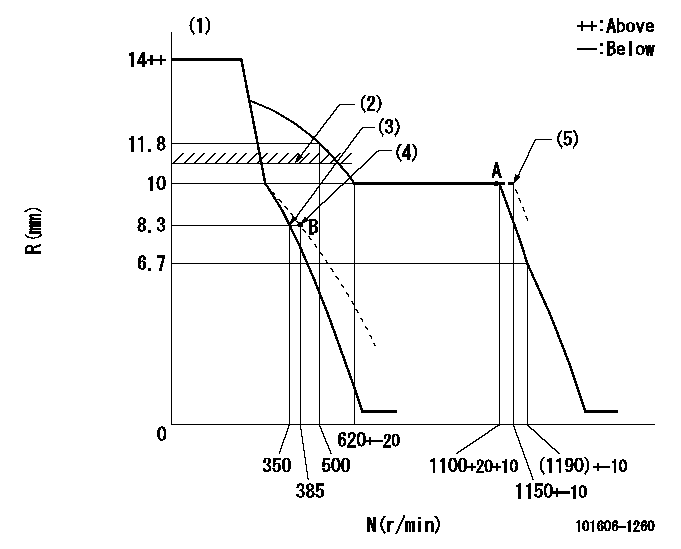

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)RACK LIMIT: RAL

(3)Main spring setting

(4)Set idle sub-spring

(5)At shipping

----------

K=15 RAL=11.5+-0.1mm

----------

----------

K=15 RAL=11.5+-0.1mm

----------

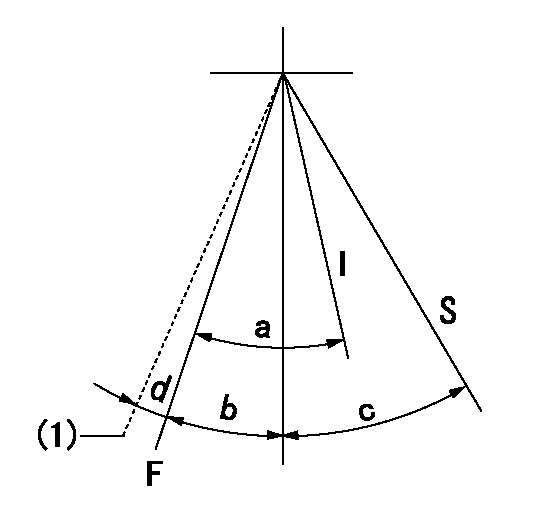

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)At shipping

----------

----------

a=24deg+-5deg b=10deg+-5deg c=32deg+-3deg d=(2deg)

----------

----------

a=24deg+-5deg b=10deg+-5deg c=32deg+-3deg d=(2deg)

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26deg+-5deg b=53deg+-5deg

----------

----------

a=26deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=19deg

----------

a=(2deg)

----------

aa=19deg

----------

a=(2deg)

Information:

You must read and understand the warnings and instructions contained in the Safety section of this manual before performing any operation or maintenance procedures.Zinc Rods

Corrosion in sea water circuits can result in premature deterioration of system components, leaks, and possible cooling system contamination. The cause for the accelerated corrosion may be the lack of sacrificial zinc anodes (rods) in the sea water system.Zinc rods are inserted in the engine's sea water cooling system to help prevent the corrosive action of salt (sea) water. The reaction of the zinc to the sea water causes the rods to deteriorate, instead of more critical engine cooling system parts. Rapid deterioration of zinc rods may indicate the presence of stray electrical currents from improperly installed or grounded electrical attachments.The zinc rods must be inspected every 50 service hours and replaced when they have deteriorated.The location and number of zinc rods depends on the individual engine and the engine's attachments. Zinc rods are located in: the heat exchanger bonnet, the aftercooler lines, the raw/sea water heat exchanger bonnet, the raw/sea water pump, and the raw/sea water lines.Inspect

1. Remove all the zinc rod assemblies. The assembly plugs are painted red for easy identification. 2. Tap the zinc rods lightly with a hammer. If the rod has deteriorated, or flakes when tapped, install a new zinc rod.Replace

1. Unscrew or drill the old rod from the plug. Clean the plug.2. Apply 9S-3263 Compound to the shoulder of a new rod. Apply the compound only to the shoulder of the rod. Install the rod into the plug.3. Coat the external threads of the plug with 5P-3413 Pipe Sealant. Install the zinc rod assembly. Refer to the Torque Specifications in this manual.

Corrosion in sea water circuits can result in premature deterioration of system components, leaks, and possible cooling system contamination. The cause for the accelerated corrosion may be the lack of sacrificial zinc anodes (rods) in the sea water system.Zinc rods are inserted in the engine's sea water cooling system to help prevent the corrosive action of salt (sea) water. The reaction of the zinc to the sea water causes the rods to deteriorate, instead of more critical engine cooling system parts. Rapid deterioration of zinc rods may indicate the presence of stray electrical currents from improperly installed or grounded electrical attachments.The zinc rods must be inspected every 50 service hours and replaced when they have deteriorated.The location and number of zinc rods depends on the individual engine and the engine's attachments. Zinc rods are located in: the heat exchanger bonnet, the aftercooler lines, the raw/sea water heat exchanger bonnet, the raw/sea water pump, and the raw/sea water lines.Inspect

1. Remove all the zinc rod assemblies. The assembly plugs are painted red for easy identification. 2. Tap the zinc rods lightly with a hammer. If the rod has deteriorated, or flakes when tapped, install a new zinc rod.Replace

1. Unscrew or drill the old rod from the plug. Clean the plug.2. Apply 9S-3263 Compound to the shoulder of a new rod. Apply the compound only to the shoulder of the rod. Install the rod into the plug.3. Coat the external threads of the plug with 5P-3413 Pipe Sealant. Install the zinc rod assembly. Refer to the Torque Specifications in this manual.