Information injection-pump assembly

ZEXEL

101606-1180

1016061180

Rating:

Cross reference number

ZEXEL

101606-1180

1016061180

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

875

875

875

Average injection quantity

mm3/st.

60.3

59.3

61.3

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.7+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

9.2

7.7

10.7

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

0.8

0.3

1.3

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

5

5

5

Remarks

Finish

Finish

Test data Ex:

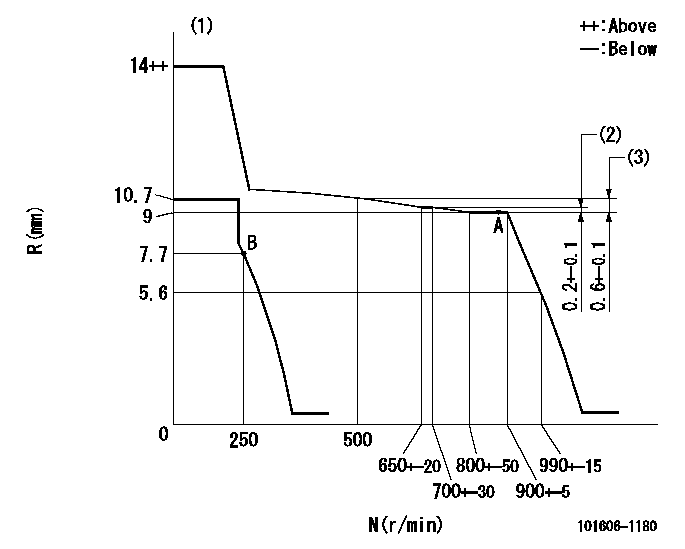

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

(3)Rack difference between N = N3 and N = N4

----------

K=5 N1=875r/min N2=670r/min N3=875r/min N4=500r/min

----------

----------

K=5 N1=875r/min N2=670r/min N3=875r/min N4=500r/min

----------

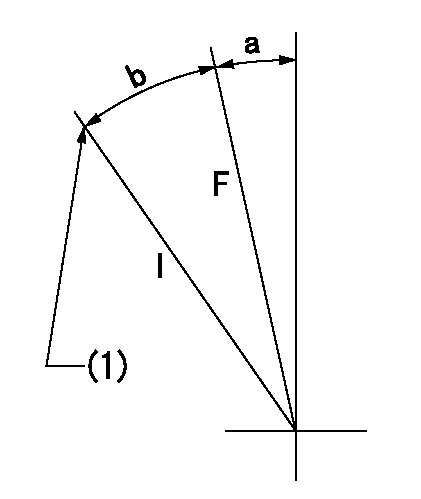

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=4deg+-5deg b=14deg+-5deg

----------

----------

a=4deg+-5deg b=14deg+-5deg

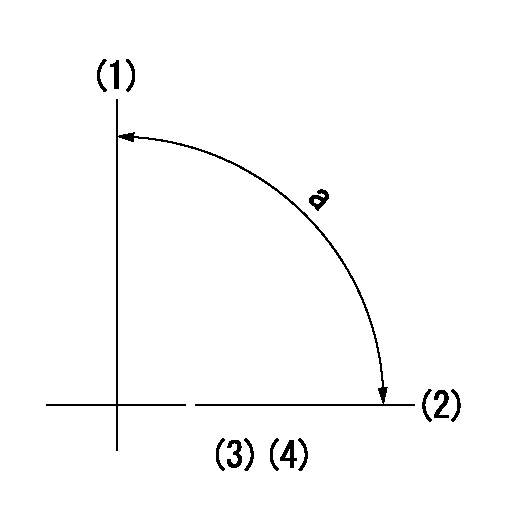

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26deg+-5deg b=53deg+-5deg

----------

----------

a=26deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '2' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(90deg)

----------

aa=18deg

----------

a=(90deg)

Information:

Contact your Caterpillar dealer for part numbers and available container sizes.

This oil is formulated for transmissions and drive trains only, and should not be used in engines. Shortened engine service life will result.Do not use Caterpillar Gear Oil (GO) in marine transmissions. Gear Oil can cause seal material to fail and possibly leak. Gear Oil also may not be compatible with friction materials and can reduce transmission efficiency.

Multi-grade oils are not currently blended by Caterpillar for use in transmissions. Multi-grade oils which use high molecular weight polymers as viscosity index improvers lose their viscosity effectiveness by permanent and temporary shear of the viscosity index improver. Therefore, multi-grade oils are not recommended for transmissions. The Caterpillar TO-4 specification does include a test for multi-grade oil shear stability. Multi-grade oils with adequate shear stability may be available in the future.Commercial Transmission/Drive Train Oils

If Caterpillar Transmission/Drive Train Oil is not used, commercial oils meeting the Caterpillar TO-4 specification must be used in Caterpillar marine transmissions:* TO-4 Specification Oils, single grade onlyCommercial Marine Transmissions

For marine transmissions which are not manufactured by Caterpillar, refer to the marine transmission or vessel OEM lubrication recommendations.S O S Oil Analysis

Caterpillar's Scheduled Oil Sampling (S O S) Oil Analysis should be a part of an engine's overall maintenance program. The S O S program monitors the engine and transmission through used oil analysis. The oil analysis measures wear metals and oil condition. Deviations from established limits or trend lines can diagnose an impending problem before the problem becomes apparent, costly, and destructive.See your Caterpillar dealer for more information regarding S O S Oil Analysis and how the program can help you manage your engine and transmission.Engine Lubricant Recommendations Summary

To achieve all the performance that was built into a Caterpillar engine, follow these guidelines:* Select the proper Caterpillar oil or commercial oil that meets the API specifications* Select the proper oil viscosity based on the applicable Lubricant Viscosities chart* Replace the engine oil and oil filter(s) at the intervals specified in the Operation and Maintenance Manual* Perform maintenance according to the Operation and Maintenance ManualCaterpillar Lubricating Grease

Caterpillar provides grease for a variety of applications and extreme temperature conditions. The descriptions of these products follow.Contact your Caterpillar dealer for part numbers and available container sizes. One grease may be incompatible with another grease. When using commercial grease, make sure the grease is compatible with the grease used in your system, or make sure to purge the system. Contact your supplier regarding grease compatibility questions.Multipurpose Grease

Multipurpose Lithium Complex Grease (MPG)

MPG is a NLGI No.2 general purpose lithium complex grease for light to medium duty applications. MPG has good high temperature characteristics, with a minimum dropping point of 260°C (500°F). MPG contains unleaded extreme pressure additives and anti-wear and corrosion inhibitors to provide extra protection in a variety of construction, agricultural and automotive applications.MPG meets the requirements for extended service intervals of automotive chassis points and wheel bearings with disc brakes, particularly in passenger cars, vans, light trucks and taxi fleets.

This oil is formulated for transmissions and drive trains only, and should not be used in engines. Shortened engine service life will result.Do not use Caterpillar Gear Oil (GO) in marine transmissions. Gear Oil can cause seal material to fail and possibly leak. Gear Oil also may not be compatible with friction materials and can reduce transmission efficiency.

Multi-grade oils are not currently blended by Caterpillar for use in transmissions. Multi-grade oils which use high molecular weight polymers as viscosity index improvers lose their viscosity effectiveness by permanent and temporary shear of the viscosity index improver. Therefore, multi-grade oils are not recommended for transmissions. The Caterpillar TO-4 specification does include a test for multi-grade oil shear stability. Multi-grade oils with adequate shear stability may be available in the future.Commercial Transmission/Drive Train Oils

If Caterpillar Transmission/Drive Train Oil is not used, commercial oils meeting the Caterpillar TO-4 specification must be used in Caterpillar marine transmissions:* TO-4 Specification Oils, single grade onlyCommercial Marine Transmissions

For marine transmissions which are not manufactured by Caterpillar, refer to the marine transmission or vessel OEM lubrication recommendations.S O S Oil Analysis

Caterpillar's Scheduled Oil Sampling (S O S) Oil Analysis should be a part of an engine's overall maintenance program. The S O S program monitors the engine and transmission through used oil analysis. The oil analysis measures wear metals and oil condition. Deviations from established limits or trend lines can diagnose an impending problem before the problem becomes apparent, costly, and destructive.See your Caterpillar dealer for more information regarding S O S Oil Analysis and how the program can help you manage your engine and transmission.Engine Lubricant Recommendations Summary

To achieve all the performance that was built into a Caterpillar engine, follow these guidelines:* Select the proper Caterpillar oil or commercial oil that meets the API specifications* Select the proper oil viscosity based on the applicable Lubricant Viscosities chart* Replace the engine oil and oil filter(s) at the intervals specified in the Operation and Maintenance Manual* Perform maintenance according to the Operation and Maintenance ManualCaterpillar Lubricating Grease

Caterpillar provides grease for a variety of applications and extreme temperature conditions. The descriptions of these products follow.Contact your Caterpillar dealer for part numbers and available container sizes. One grease may be incompatible with another grease. When using commercial grease, make sure the grease is compatible with the grease used in your system, or make sure to purge the system. Contact your supplier regarding grease compatibility questions.Multipurpose Grease

Multipurpose Lithium Complex Grease (MPG)

MPG is a NLGI No.2 general purpose lithium complex grease for light to medium duty applications. MPG has good high temperature characteristics, with a minimum dropping point of 260°C (500°F). MPG contains unleaded extreme pressure additives and anti-wear and corrosion inhibitors to provide extra protection in a variety of construction, agricultural and automotive applications.MPG meets the requirements for extended service intervals of automotive chassis points and wheel bearings with disc brakes, particularly in passenger cars, vans, light trucks and taxi fleets.