Information injection-pump assembly

ZEXEL

101606-1161

1016061161

Rating:

Cross reference number

ZEXEL

101606-1161

1016061161

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.8

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

60

58.1

61.9

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.5+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

9.3

8.2

10.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.8)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

60

59

61

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.6

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

80.5

78.5

82.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

2.4

1.9

2.9

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

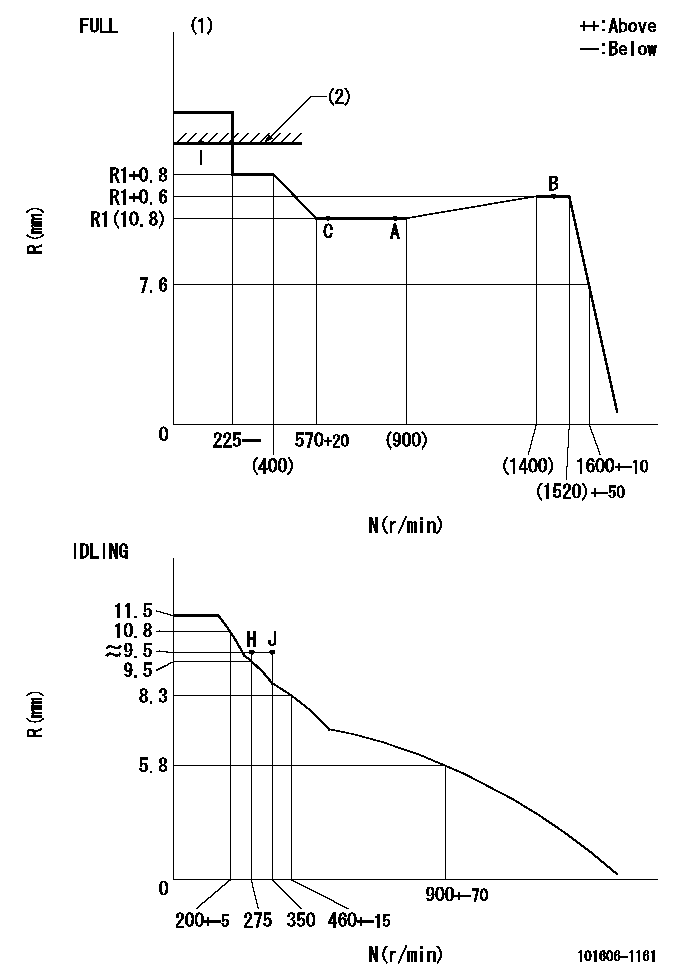

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C70

----------

----------

T1=C70

----------

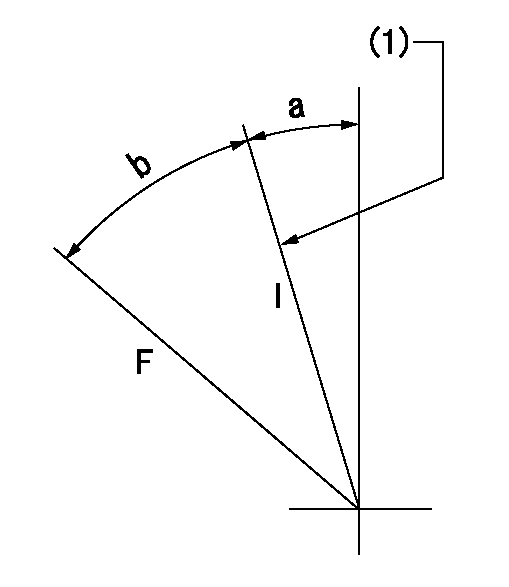

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=10deg+-5deg b=(46deg)+-3deg

----------

----------

a=10deg+-5deg b=(46deg)+-3deg

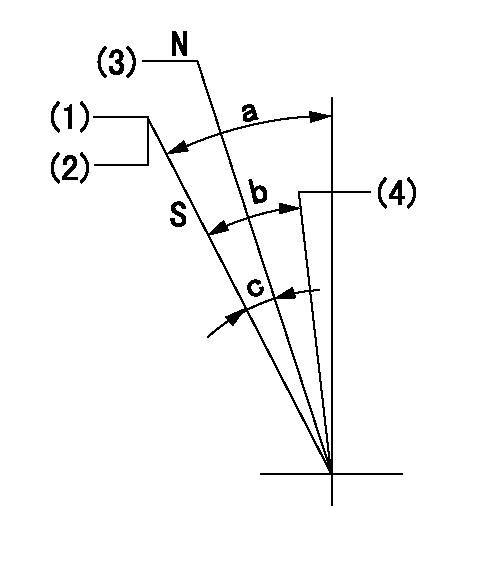

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at speed = rated point and rack position = aa (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt , confirm non-injection at pump speed bb. Rack position = cc (non-injection rack position).

(3)Rack position = approximately dd

(4)Free (at shipping)

----------

aa=7.1mm bb=275r/min cc=8.8mm dd=15mm

----------

a=38deg+-5deg b=(26.5deg) c=12.5deg+-3deg

----------

aa=7.1mm bb=275r/min cc=8.8mm dd=15mm

----------

a=38deg+-5deg b=(26.5deg) c=12.5deg+-3deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.2mm

----------

----------

N1=400+-5r/min Ra=9.2mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

Raw/Sea Water Pump Failure

The raw/sea water pump circulates sea or fresh water through the engine jacket water heat exchanger. If the raw/sea water pump should fail, follow the procedure below to continue engine operation.

Shut off valve-normally closed (1), emergency raw/sea water pump (2), emergency raw/sea water inlet (3), inlet valve-normally closed (4), emergency raw/sea water strainers (5), normal operation raw/sea water strainers (6), normal operation raw/sea water inlet (7), inlet valve-normally open (8), raw/sea water pump (9), jacket water heat exchanger (10), raw/sea water outlet (11), and aftercooler (12).1. Stop the engine. If the shaft bearing has failed, the pump does NOT need to be removed.2. Close inlet valve (8) to raw/sea water strainers (6) and raw/sea water pump (9).3. Open inlet valve (4) to emergency raw/sea water pump (2). Start and prime the pump.4. Start the engine. Engage the marine gear and continue operation at normal speed.Engine Lube Oil Pump Failure

If the engine lube oil pump fails, the oil pressure will drop and the engine jacket water temperature gauge reading will be above normal. The applicable engine shutoff controls (if equipped) will stop the engine. Refer to the following procedure to use the emergency lube oil pump.1. Place the marine gear in the NEUTRAL position. Stop the engine (if the engine is still running).2. Measure the engine oil level. Ensure the oil level is between the ADD and FULL marks on the dipstick. Add oil if necessary.3. Reset the oil pressure shutoff control (if equipped). Be sure that the oil pressure shutoff control RESET is in the RUN position to enable engine starting.4. Start the emergency standby lube oil pump. Observe the oil pressure gauge5. Start the engine. Engage the marine gear and operate the vessel at normal speed.Turbocharger Failure

Air cleaner (1), turbocharger air inlet hose (2), compressor (3), clamp (4), cartridge (5), turbine housing (6), oil supply line (7), aftercooler air inlet hose (8), and oil drain line (9).1. Remove air cleaner (1) and turbocharger air inlet hose (2).2. Remove oil supply line (7) from the top of cartridge (5). Remove oil supply line (7) from the cylinder block. Plug the oil supply opening in the cylinder block.3. Remove oil drain line (9) from the bottom of cartridge (5). Remove oil drain line (9) from the flywheel housing. Plug the oil drain opening in the flyheel housing.4. Remove the bolts from the flange to aftercooler air inlet hose (8).5. Remove clamp (4) while supporting compressor (3) and aftercooler air inlet hose (8). Remove aftercooler air inlet hose (8), compressor (3) and cartridge (5) as a unit.

DO NOT allow exhaust gas to discharge into engine room. Vent the exhaust to the outside and be sure venting systems are correctly installed and operating. Diesel engine exhaust contains products of combustion which may be harmful to your health.

6. Provide some means of attaching a flat steel against the opening in turbine housing (6) where cartridge (5) was removed. The plate must be large enough to completely cover the opening.

The raw/sea water pump circulates sea or fresh water through the engine jacket water heat exchanger. If the raw/sea water pump should fail, follow the procedure below to continue engine operation.

Shut off valve-normally closed (1), emergency raw/sea water pump (2), emergency raw/sea water inlet (3), inlet valve-normally closed (4), emergency raw/sea water strainers (5), normal operation raw/sea water strainers (6), normal operation raw/sea water inlet (7), inlet valve-normally open (8), raw/sea water pump (9), jacket water heat exchanger (10), raw/sea water outlet (11), and aftercooler (12).1. Stop the engine. If the shaft bearing has failed, the pump does NOT need to be removed.2. Close inlet valve (8) to raw/sea water strainers (6) and raw/sea water pump (9).3. Open inlet valve (4) to emergency raw/sea water pump (2). Start and prime the pump.4. Start the engine. Engage the marine gear and continue operation at normal speed.Engine Lube Oil Pump Failure

If the engine lube oil pump fails, the oil pressure will drop and the engine jacket water temperature gauge reading will be above normal. The applicable engine shutoff controls (if equipped) will stop the engine. Refer to the following procedure to use the emergency lube oil pump.1. Place the marine gear in the NEUTRAL position. Stop the engine (if the engine is still running).2. Measure the engine oil level. Ensure the oil level is between the ADD and FULL marks on the dipstick. Add oil if necessary.3. Reset the oil pressure shutoff control (if equipped). Be sure that the oil pressure shutoff control RESET is in the RUN position to enable engine starting.4. Start the emergency standby lube oil pump. Observe the oil pressure gauge5. Start the engine. Engage the marine gear and operate the vessel at normal speed.Turbocharger Failure

Air cleaner (1), turbocharger air inlet hose (2), compressor (3), clamp (4), cartridge (5), turbine housing (6), oil supply line (7), aftercooler air inlet hose (8), and oil drain line (9).1. Remove air cleaner (1) and turbocharger air inlet hose (2).2. Remove oil supply line (7) from the top of cartridge (5). Remove oil supply line (7) from the cylinder block. Plug the oil supply opening in the cylinder block.3. Remove oil drain line (9) from the bottom of cartridge (5). Remove oil drain line (9) from the flywheel housing. Plug the oil drain opening in the flyheel housing.4. Remove the bolts from the flange to aftercooler air inlet hose (8).5. Remove clamp (4) while supporting compressor (3) and aftercooler air inlet hose (8). Remove aftercooler air inlet hose (8), compressor (3) and cartridge (5) as a unit.

DO NOT allow exhaust gas to discharge into engine room. Vent the exhaust to the outside and be sure venting systems are correctly installed and operating. Diesel engine exhaust contains products of combustion which may be harmful to your health.

6. Provide some means of attaching a flat steel against the opening in turbine housing (6) where cartridge (5) was removed. The plate must be large enough to completely cover the opening.