Information injection-pump assembly

ZEXEL

101606-1132

1016061132

MITSUBISHI

ME076012

me076012

Rating:

Cross reference number

ZEXEL

101606-1132

1016061132

MITSUBISHI

ME076012

me076012

Zexel num

Bosch num

Firm num

Name

101606-1132

ME076012 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D15 * K

6D15 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

69

66.9

71.1

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.9+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

9.2

8.1

10.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

69

68

70

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.35

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

82.5

78.5

86.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.2

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

47.6

43.6

51.6

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

2.4

1.9

2.9

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

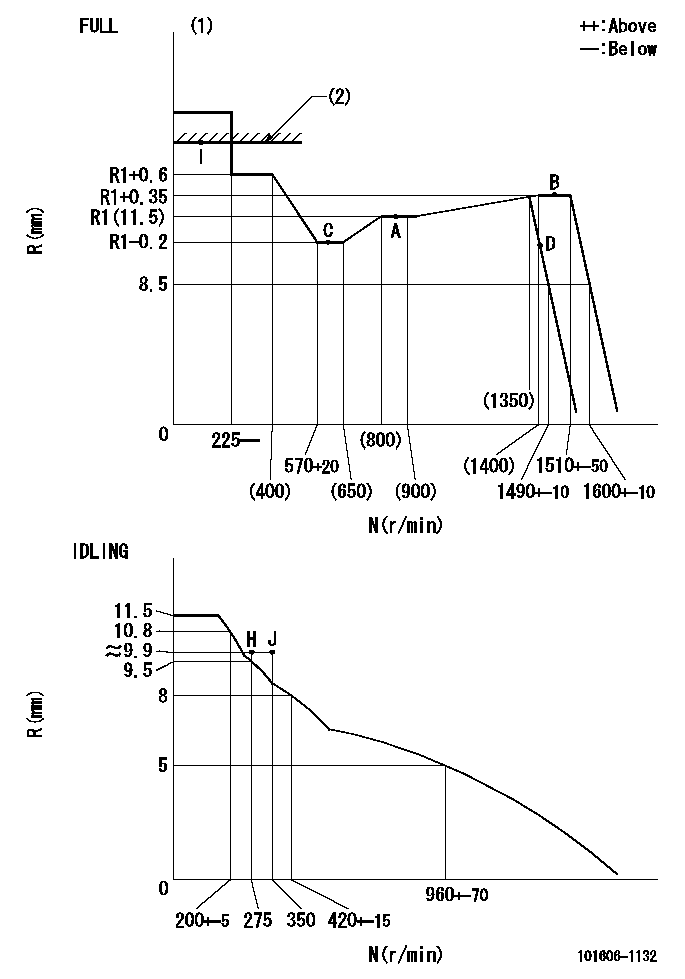

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C92

----------

----------

T1=C92

----------

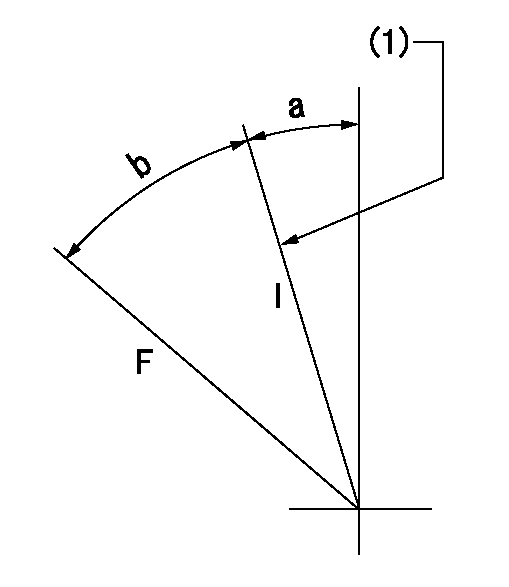

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=(42deg)+-3deg

----------

----------

a=18.5deg+-5deg b=(42deg)+-3deg

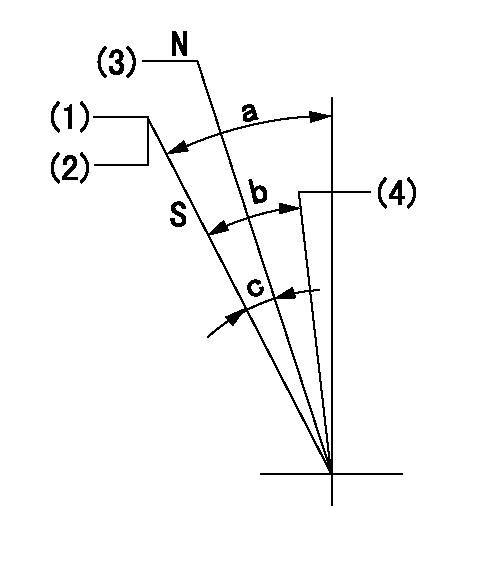

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at speed = rated point and rack position = aa (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt , confirm non-injection at pump speed bb. Rack position = cc (non-injection rack position).

(3)Rack position = approximately dd

(4)Free (at shipping)

----------

aa=(7)mm bb=275r/min cc=(8)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

----------

aa=(7)mm bb=275r/min cc=(8)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

0000001201

I:Idle

F:At operation, hold it in the full speed position.

(1)Rack position = aa, speed = bb.

----------

aa=8.5mm bb=1490r/min

----------

a=15deg+-5deg b=(36deg)+-3deg

----------

aa=8.5mm bb=1490r/min

----------

a=15deg+-5deg b=(36deg)+-3deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.7mm

----------

----------

N1=400+-5r/min Ra=9.7mm

----------

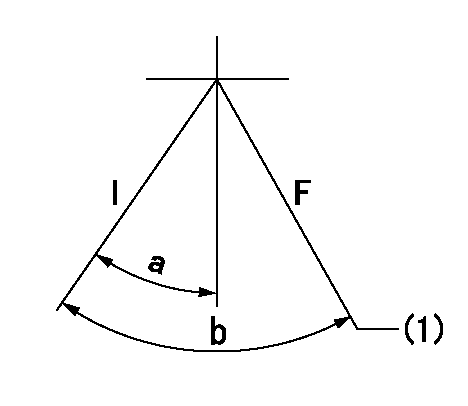

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

Engine Description

Older 3408 and 3412 models may by precombustion chamber (PC) type engines. Newer 3408 and 3412 models are direct injection (DI) engines.A mechanical governor controls the fuel injection pump output to maintain the engine rpm selected by the operator. The fuel injection pump meters and pumps fuel under high pressure to a fuel injection nozzle for each cylinder. An automatic timing device advances or retards fuel injection to provide the best fuel injection timing over the full range of engine speed.The air/fuel ratio control, located on the governor, restricts the movement of the fuel rack, allowing only the proper amount of fuel to be injected into the cylinders during acceleration, to minimize exhaust smoke.These engines are available as turbocharged (T) or turbocharged and aftercooled (TA). Inlet air is filtered by an air cleaner before entering the engine cylinders. In turbocharged engines, the filtered inlet air is compressed by a turbocharger before entering the engine cylinders. The turbocharger is driven by the engine exhaust.There are four in-head valves (two inlet valves and two exhaust valves) for each cylinder. The camshaft actuates the rocker arms and the valves through mechanical lifters and push rods.The jacket water cooling system uses an expansion tank and a gear driven centrifugal water pump. The engine coolant is circulated by passing through the oil cooler first, then to the engine block and cylinder head. One water temperature regulator for each cylinder bank regulates engine coolant temperature by restricting coolant flow for quick engine warm-up. The regulator opens to allow free circulation of coolant after operating temperature has been reached.The watercooled exhaust manifolds, risers and turbochargers are designed to minimize radiated heat in the engine room.Lubrication of the engine is accomplished by a gear-type pump and bypass valves. The pump provides full pressure lubrication to the engine internal and external parts. The engine lubricating oil (both cooled and filtered) provides unrestricted flow to engine parts when oil viscosity is high or if the oil cooler is restricted or if the oil filter elements become plugged.The engines are available with SAE standard counterclockwise rotation (CCW when viewed from rear of engine). The engines can be equipped with either the SAE No.1 flywheel or the SAE No.0 flywheel to mate with various marine gears. Several marine gear manufacturers offer marine transmissions for the engines through local distributors.Engine Specifications

3408 Engine

3412 Engine

Older 3408 and 3412 models may by precombustion chamber (PC) type engines. Newer 3408 and 3412 models are direct injection (DI) engines.A mechanical governor controls the fuel injection pump output to maintain the engine rpm selected by the operator. The fuel injection pump meters and pumps fuel under high pressure to a fuel injection nozzle for each cylinder. An automatic timing device advances or retards fuel injection to provide the best fuel injection timing over the full range of engine speed.The air/fuel ratio control, located on the governor, restricts the movement of the fuel rack, allowing only the proper amount of fuel to be injected into the cylinders during acceleration, to minimize exhaust smoke.These engines are available as turbocharged (T) or turbocharged and aftercooled (TA). Inlet air is filtered by an air cleaner before entering the engine cylinders. In turbocharged engines, the filtered inlet air is compressed by a turbocharger before entering the engine cylinders. The turbocharger is driven by the engine exhaust.There are four in-head valves (two inlet valves and two exhaust valves) for each cylinder. The camshaft actuates the rocker arms and the valves through mechanical lifters and push rods.The jacket water cooling system uses an expansion tank and a gear driven centrifugal water pump. The engine coolant is circulated by passing through the oil cooler first, then to the engine block and cylinder head. One water temperature regulator for each cylinder bank regulates engine coolant temperature by restricting coolant flow for quick engine warm-up. The regulator opens to allow free circulation of coolant after operating temperature has been reached.The watercooled exhaust manifolds, risers and turbochargers are designed to minimize radiated heat in the engine room.Lubrication of the engine is accomplished by a gear-type pump and bypass valves. The pump provides full pressure lubrication to the engine internal and external parts. The engine lubricating oil (both cooled and filtered) provides unrestricted flow to engine parts when oil viscosity is high or if the oil cooler is restricted or if the oil filter elements become plugged.The engines are available with SAE standard counterclockwise rotation (CCW when viewed from rear of engine). The engines can be equipped with either the SAE No.1 flywheel or the SAE No.0 flywheel to mate with various marine gears. Several marine gear manufacturers offer marine transmissions for the engines through local distributors.Engine Specifications

3408 Engine

3412 Engine

Have questions with 101606-1132?

Group cross 101606-1132 ZEXEL

Mitsubishi

101606-1132

ME076012

INJECTION-PUMP ASSEMBLY

6D15

6D15