Information injection-pump assembly

ZEXEL

101606-1131

1016061131

Rating:

Cross reference number

ZEXEL

101606-1131

1016061131

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

11

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

60

58.1

61.9

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

10+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

10

8.9

11.1

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

60

59

61

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.6

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

80.5

78.5

82.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

2.4

1.9

2.9

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

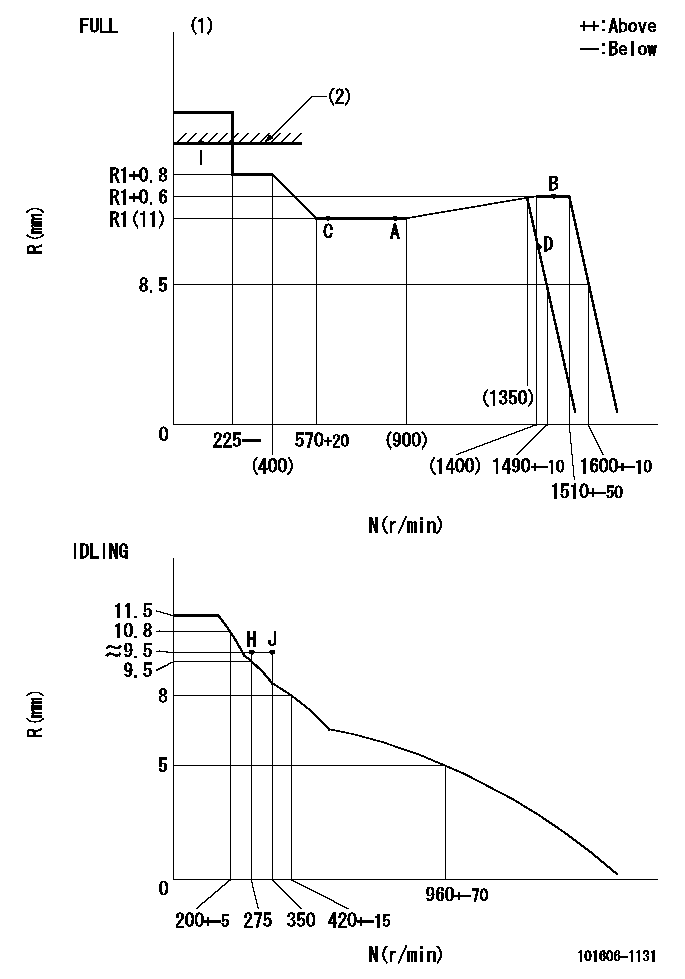

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C69

----------

----------

T1=C69

----------

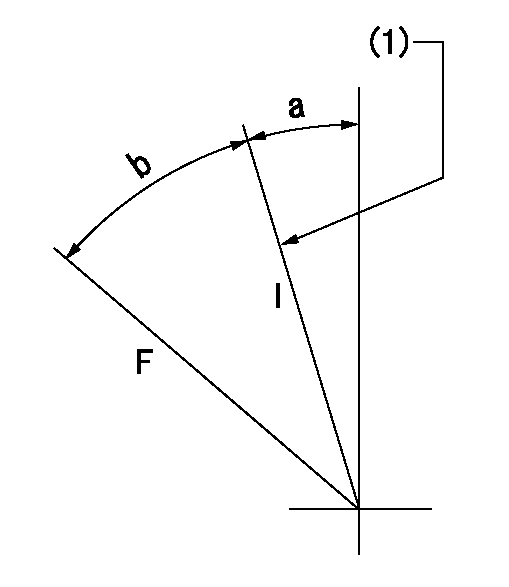

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=(42deg)+-3deg

----------

----------

a=18.5deg+-5deg b=(42deg)+-3deg

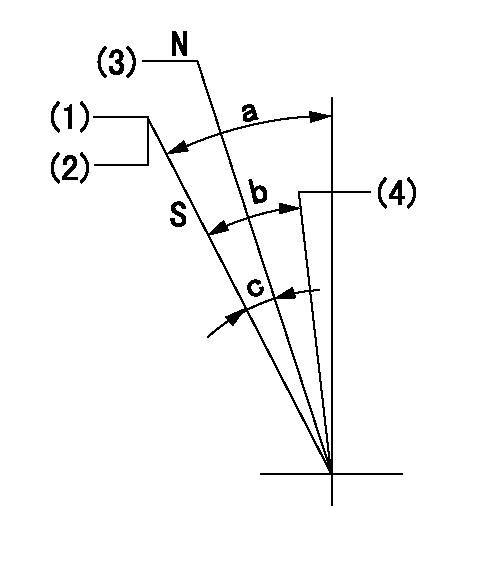

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at speed = rated point and rack position = aa (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt , confirm non-injection at pump speed bb. Rack position = cc (non-injection rack position).

(3)Rack position = approximately dd

(4)Free (at shipping)

----------

aa=(7)mm bb=275r/min cc=(8)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

----------

aa=(7)mm bb=275r/min cc=(8)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

0000001201

I:Idle

F:At operation, hold it in the full speed position.

(1)Rack position = aa, speed = bb.

----------

aa=8.5mm bb=1490r/min

----------

a=15deg+-5deg b=(36deg)+-3deg

----------

aa=8.5mm bb=1490r/min

----------

a=15deg+-5deg b=(36deg)+-3deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.2mm

----------

----------

N1=400+-5r/min Ra=9.2mm

----------

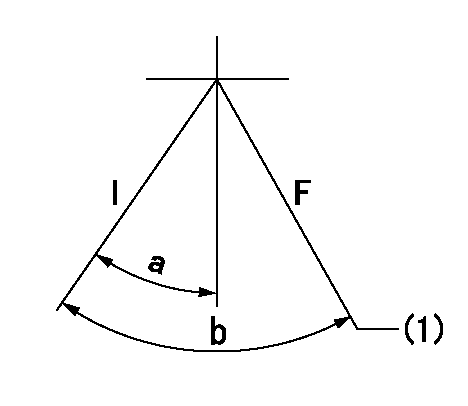

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

Fire Extinguisher

Have a fire extinguisher available and know how to use it. Inspect and have it serviced as recommended on its instruction plate.Crushing or Cutting Prevention

Support equipment and attachments properly when working beneath them.Never attempt adjustments while the engine is running unless otherwise specified in this manual.Stay clear of all rotating and moving parts. Guards should be in place whenever maintenance is not being performed.Keep objects away from moving fan blades. They will throw or cut any object or tool that falls or is pushed into them.Wear protective glasses when striking objects to avoid injury to your eyes.Chips or other debris can fly off objects when struck. Make sure no one can be injured by flying debris before striking any object.Mounting and Dismounting

Do not climb on, or jump off the engine or stand on components which cannot support your weight. Use an adequate ladder. Always use steps and handholds when mounting and dismounting.Clean steps, handholds and areas of the engine you will be working on or around.Before Starting the Engine

Inspect engine for potential hazards.Be sure all protective guards and covers are installed if an engine must be started to make adjustments or checks. To help prevent an accident caused by parts in rotation, work carefully around them.Do not disable or bypass automatic shutoff circuits. They are provided to prevent personal injury and engine damage.Never start an engine with the governor linkage disconnected.Make provisions for shutting off the air or fuel supply to stop the engine if there is an overspeed on start-up after performing repair or maintenance to the engine.See the Maintenance section of this manual for adjustment, or the Service Manual for repairs.Engine Starting

DO NOT start the engine or move any of the controls if there is a warning tag attached to the controls. Check with the person who attached the tag before starting.Make sure no one is working on, or close to the engine or engine driven components before starting it. Always make an inspection of the engine before and after starting.Start the engine only from the operator's station. Never short across the starter terminals or the batteries as this could bypass the engine neutral-start system as well as damage the electrical system.Always start the engine according to the required Engine Starting procedure described in this manual to prevent major engine component damage and personal injury.Make sure the engine is equipped with a lighting system as required by conditions.Make sure all lights are working properly.Check the jacket water and oil temperature gauges frequently during the operation of jacket water and/or lube oil heaters to ensure proper operation.Diesel engine exhaust contains products of combustion which may be harmful to your health. Always start and operate the engine in a well-ventilated area and, if in an enclosed area, vent the exhaust to the outside.Ether

Ether is poisonous and flammable.Inhaling ether vapors or repeated contact of ether with skin can cause personal injury.Do not smoke while changing ether cylinders.Use ether only in well ventilated areas.Use ether with care to avoid

Have a fire extinguisher available and know how to use it. Inspect and have it serviced as recommended on its instruction plate.Crushing or Cutting Prevention

Support equipment and attachments properly when working beneath them.Never attempt adjustments while the engine is running unless otherwise specified in this manual.Stay clear of all rotating and moving parts. Guards should be in place whenever maintenance is not being performed.Keep objects away from moving fan blades. They will throw or cut any object or tool that falls or is pushed into them.Wear protective glasses when striking objects to avoid injury to your eyes.Chips or other debris can fly off objects when struck. Make sure no one can be injured by flying debris before striking any object.Mounting and Dismounting

Do not climb on, or jump off the engine or stand on components which cannot support your weight. Use an adequate ladder. Always use steps and handholds when mounting and dismounting.Clean steps, handholds and areas of the engine you will be working on or around.Before Starting the Engine

Inspect engine for potential hazards.Be sure all protective guards and covers are installed if an engine must be started to make adjustments or checks. To help prevent an accident caused by parts in rotation, work carefully around them.Do not disable or bypass automatic shutoff circuits. They are provided to prevent personal injury and engine damage.Never start an engine with the governor linkage disconnected.Make provisions for shutting off the air or fuel supply to stop the engine if there is an overspeed on start-up after performing repair or maintenance to the engine.See the Maintenance section of this manual for adjustment, or the Service Manual for repairs.Engine Starting

DO NOT start the engine or move any of the controls if there is a warning tag attached to the controls. Check with the person who attached the tag before starting.Make sure no one is working on, or close to the engine or engine driven components before starting it. Always make an inspection of the engine before and after starting.Start the engine only from the operator's station. Never short across the starter terminals or the batteries as this could bypass the engine neutral-start system as well as damage the electrical system.Always start the engine according to the required Engine Starting procedure described in this manual to prevent major engine component damage and personal injury.Make sure the engine is equipped with a lighting system as required by conditions.Make sure all lights are working properly.Check the jacket water and oil temperature gauges frequently during the operation of jacket water and/or lube oil heaters to ensure proper operation.Diesel engine exhaust contains products of combustion which may be harmful to your health. Always start and operate the engine in a well-ventilated area and, if in an enclosed area, vent the exhaust to the outside.Ether

Ether is poisonous and flammable.Inhaling ether vapors or repeated contact of ether with skin can cause personal injury.Do not smoke while changing ether cylinders.Use ether only in well ventilated areas.Use ether with care to avoid