Information injection-pump assembly

ZEXEL

101606-1111

1016061111

Rating:

Cross reference number

ZEXEL

101606-1111

1016061111

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

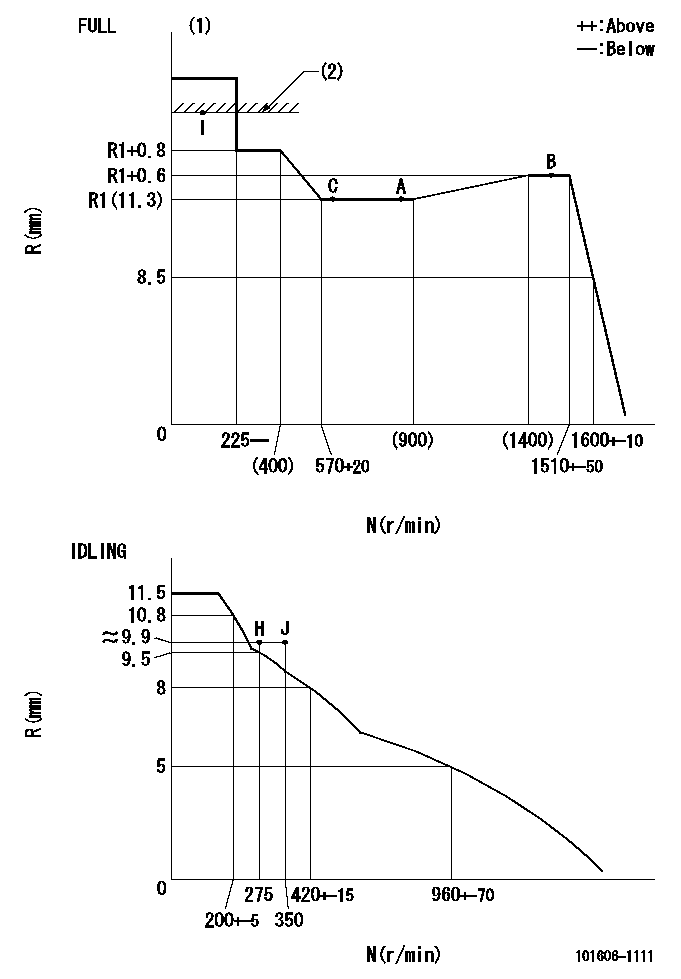

Injection quantity adjustment

Adjusting point

-

Rack position

11.3

Pump speed

r/min

850

850

850

Each cylinder's injection qty

mm3/st.

65.4

63.5

67.3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

9.9+-0.5

Pump speed

r/min

275

275

275

Each cylinder's injection qty

mm3/st.

9.2

8.1

10.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

65.4

64.4

66.4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.6

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

81.2

77.2

85.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1(11.3)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

49.5

45.5

53.5

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

75

85

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1250--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1350

Advance angle

deg.

2.4

1.9

2.9

Timer adjustment_04

Pump speed

r/min

1500

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=C69

----------

----------

T1=C69

----------

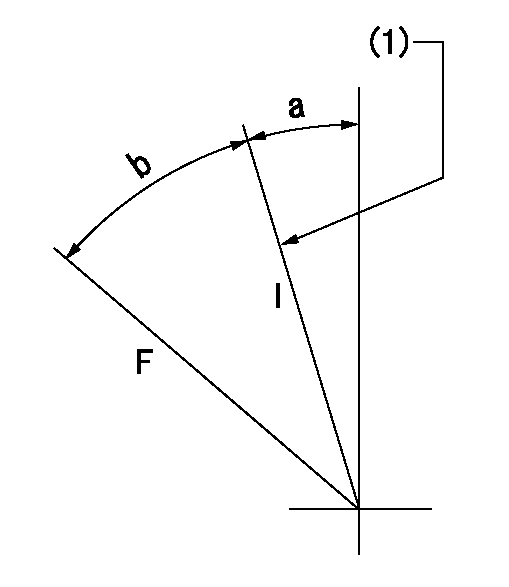

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=18.5deg+-5deg b=(42deg)+-3deg

----------

----------

a=18.5deg+-5deg b=(42deg)+-3deg

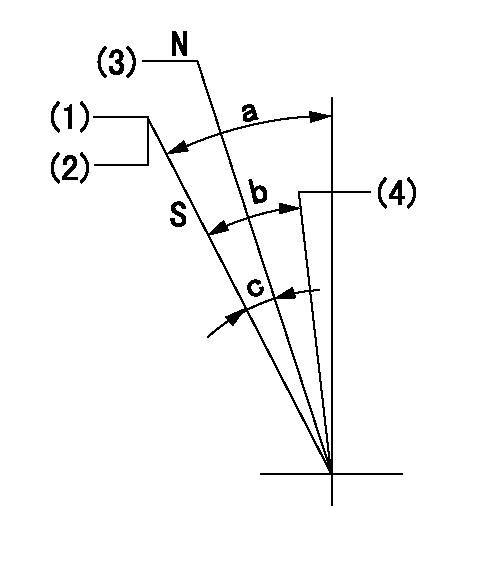

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Set the stopper bolt at speed = rated point and rack position = aa (non-injection rack position). Confirm non-injection.

(2)After setting the stopper bolt , confirm non-injection at pump speed bb. Rack position = cc (non-injection rack position).

(3)Rack position = approximately dd

(4)Free (at shipping)

----------

aa=7mm bb=275r/min cc=(8)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

----------

aa=7mm bb=275r/min cc=(8)mm dd=17.4mm

----------

a=38.5deg+-5deg b=(27deg) c=17deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=400+-5r/min Ra=9.7mm

----------

----------

N1=400+-5r/min Ra=9.7mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(1deg)

----------

aa=12deg

----------

a=(1deg)

Information:

Lubricant Viscosity Recommendations

The proper SAE grade of oil to select is determined by the minimum outside temperature at which the engine will be started and the maximum outside temperature in which the engine will be operating. This recommendation is to ensure the correct viscosity is used until the next oil change. Engine start-up at lower than specified ambient temperature requires caution. Start-up at very low ambient temperatures may require a jacket water heater, auxiliary oil heaters or other methods to increase the engine crankcase and surrounding temperatures. When operating below -20°C (-4°F) refer to Caterpillar for information.The use of multi-viscosity oils is preferred because of full protection through a wider temperature range. See chart for recommended viscosity and temperature range. To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting. If the oil will flow off, the oil is fluid enough to circulate properly.Lubricant Viscosity Chart

Refill Capacities

Engine Crankcase Oil Capacity

The crankcase refill capacities reflect the engine crankcase capacity plus on-engine oil filter change. If equipped with an auxiliary oil filter system, consult the oil filter system manufacturer for information.Total Cooling System Capacity

The Total Cooling System capacity will vary, depending on the engine model (3114 or 3116), radiator system size and capacity provided by truck/vehicle manufacturer. In order to properly maintain the cooling system, Total Cooling System capacity must be known. The chart below is left blank and should be filled in by the customer to determine the Total Cooling System Capacity for his engine and application.Add 0.25 liter (0.5 U.S. pint) of Caterpillar liquid supplemental coolant additive (Conditioner) for every 30 liter (8 U.S. gallon) of cooling system capacity to maintain the cooling system at Every 250 Service Hours.

The proper SAE grade of oil to select is determined by the minimum outside temperature at which the engine will be started and the maximum outside temperature in which the engine will be operating. This recommendation is to ensure the correct viscosity is used until the next oil change. Engine start-up at lower than specified ambient temperature requires caution. Start-up at very low ambient temperatures may require a jacket water heater, auxiliary oil heaters or other methods to increase the engine crankcase and surrounding temperatures. When operating below -20°C (-4°F) refer to Caterpillar for information.The use of multi-viscosity oils is preferred because of full protection through a wider temperature range. See chart for recommended viscosity and temperature range. To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting. If the oil will flow off, the oil is fluid enough to circulate properly.Lubricant Viscosity Chart

Refill Capacities

Engine Crankcase Oil Capacity

The crankcase refill capacities reflect the engine crankcase capacity plus on-engine oil filter change. If equipped with an auxiliary oil filter system, consult the oil filter system manufacturer for information.Total Cooling System Capacity

The Total Cooling System capacity will vary, depending on the engine model (3114 or 3116), radiator system size and capacity provided by truck/vehicle manufacturer. In order to properly maintain the cooling system, Total Cooling System capacity must be known. The chart below is left blank and should be filled in by the customer to determine the Total Cooling System Capacity for his engine and application.Add 0.25 liter (0.5 U.S. pint) of Caterpillar liquid supplemental coolant additive (Conditioner) for every 30 liter (8 U.S. gallon) of cooling system capacity to maintain the cooling system at Every 250 Service Hours.