Information injection-pump assembly

ZEXEL

101606-1090

1016061090

Rating:

Cross reference number

ZEXEL

101606-1090

1016061090

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-5520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.2

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

73.8

72.8

74.8

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

12.6

11.1

14.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1400

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

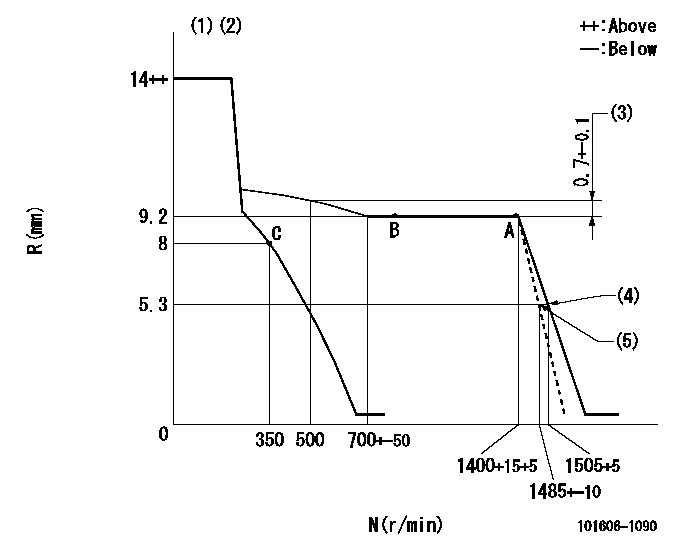

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Supplied with torque spring not set.

(3)Rack difference between N = N1 and N = N2

(4)Set idle sub-spring

(5)Main spring setting

----------

K=11 N1=1400r/min N2=500r/min

----------

----------

K=11 N1=1400r/min N2=500r/min

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=27deg+-5deg b=17deg+-5deg

----------

----------

a=27deg+-5deg b=17deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26deg+-5deg b=53deg+-5deg

----------

----------

a=26deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's tooth at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=18deg

----------

a=(2deg)

----------

aa=18deg

----------

a=(2deg)

Information:

Air Inlet Heater

To aid cold weather starting and reduce white smoke at start-up, the Caterpillar 3114 and 3116 diesel engines are equipped with an electric air heater grid located at the air inlet elbow. The heater control module senses engine oil pressure, engine coolant temperature, and time. Under the proper conditions, the control module activates a switch (solenoid), which turns the heater on and off. The heater grid, solenoid, control module and sensors are part of the engine arrangement.Operation

The air inlet heater system is designed to provide heat prior to start-up, during cranking, and after the engine has started. If the coolant temperature is below the preset limit, the control module allows the heater to stay on for pre-heating up to 30 seconds when the ignition is turned to the RUN position. An indicator lamp in the instrument panel is lit when the unit is on.Lamp Test

When the ignition switch is turned to the RUN position, the control module energizes the switch, supplying the heater element with power for two seconds. The indicator lamp in the instrument panel will illuminate at that time. Failure of the lamp to light indicates a system malfunction. If the coolant temperature is below the preset limit, the system should go directly from the lamp test into the pre-heat cycle (lamp will NOT turn off). For more detailed information on the air inlet heater, consult the Systems Operation section of the Truck Engine Service Manual.Refer to the Truck Owner Manual for starting procedures relating to the use of coolant and/or crankcase oil heaters.Priming Fuel System After Filter Change

After changing the fuel filter(s), prime (purge) the fuel system to remove air bubbes from the system. DO NOT remove the plug in the fuel filter base to release air from the fuel system while priming. Periodic removal of the plug will result in increased wear of the threads in the fuel filter base and lead to fuel leakage. 1. Loosen Fuel Filter Air Bleed Vent Cap two full turns. Unlock and operate the priming pump plunger until fuel appears at the cap. Use a cloth or container to catch excess fuel. Twenty five to thirty pump strokes may be required to fill filter.2. Tighten Fuel Filter Air Bleed Cap and continue to operate priming pump until a resistance is felt. Push the plunger in and tighten by hand and promptly continue with next step.

Do not crank the engine continuously for more than 30 seconds. Allow the starter to cool for two minutes before cranking again.

3. Crank the engine promptly after pressurizing fuel system. The engine should start within 15 seconds.4. If the engine will not start, or once started continues to misfire or smoke, further priming is necessary to help purge fuel system of air before air bubbles enter fuel injectors. Allow starting motor two minutes to cool and repeat step #2 and crank again.5. If the engine starts, but runs rough, then continue to run the engine at low idle until fuel flows free

To aid cold weather starting and reduce white smoke at start-up, the Caterpillar 3114 and 3116 diesel engines are equipped with an electric air heater grid located at the air inlet elbow. The heater control module senses engine oil pressure, engine coolant temperature, and time. Under the proper conditions, the control module activates a switch (solenoid), which turns the heater on and off. The heater grid, solenoid, control module and sensors are part of the engine arrangement.Operation

The air inlet heater system is designed to provide heat prior to start-up, during cranking, and after the engine has started. If the coolant temperature is below the preset limit, the control module allows the heater to stay on for pre-heating up to 30 seconds when the ignition is turned to the RUN position. An indicator lamp in the instrument panel is lit when the unit is on.Lamp Test

When the ignition switch is turned to the RUN position, the control module energizes the switch, supplying the heater element with power for two seconds. The indicator lamp in the instrument panel will illuminate at that time. Failure of the lamp to light indicates a system malfunction. If the coolant temperature is below the preset limit, the system should go directly from the lamp test into the pre-heat cycle (lamp will NOT turn off). For more detailed information on the air inlet heater, consult the Systems Operation section of the Truck Engine Service Manual.Refer to the Truck Owner Manual for starting procedures relating to the use of coolant and/or crankcase oil heaters.Priming Fuel System After Filter Change

After changing the fuel filter(s), prime (purge) the fuel system to remove air bubbes from the system. DO NOT remove the plug in the fuel filter base to release air from the fuel system while priming. Periodic removal of the plug will result in increased wear of the threads in the fuel filter base and lead to fuel leakage. 1. Loosen Fuel Filter Air Bleed Vent Cap two full turns. Unlock and operate the priming pump plunger until fuel appears at the cap. Use a cloth or container to catch excess fuel. Twenty five to thirty pump strokes may be required to fill filter.2. Tighten Fuel Filter Air Bleed Cap and continue to operate priming pump until a resistance is felt. Push the plunger in and tighten by hand and promptly continue with next step.

Do not crank the engine continuously for more than 30 seconds. Allow the starter to cool for two minutes before cranking again.

3. Crank the engine promptly after pressurizing fuel system. The engine should start within 15 seconds.4. If the engine will not start, or once started continues to misfire or smoke, further priming is necessary to help purge fuel system of air before air bubbles enter fuel injectors. Allow starting motor two minutes to cool and repeat step #2 and crank again.5. If the engine starts, but runs rough, then continue to run the engine at low idle until fuel flows free